Elemental oxygen degradation resistant polyimide material and method of producing the same

A technology of polyimide and anti-atomic oxygen, applied in the field of organic-inorganic hybrid polyimide materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

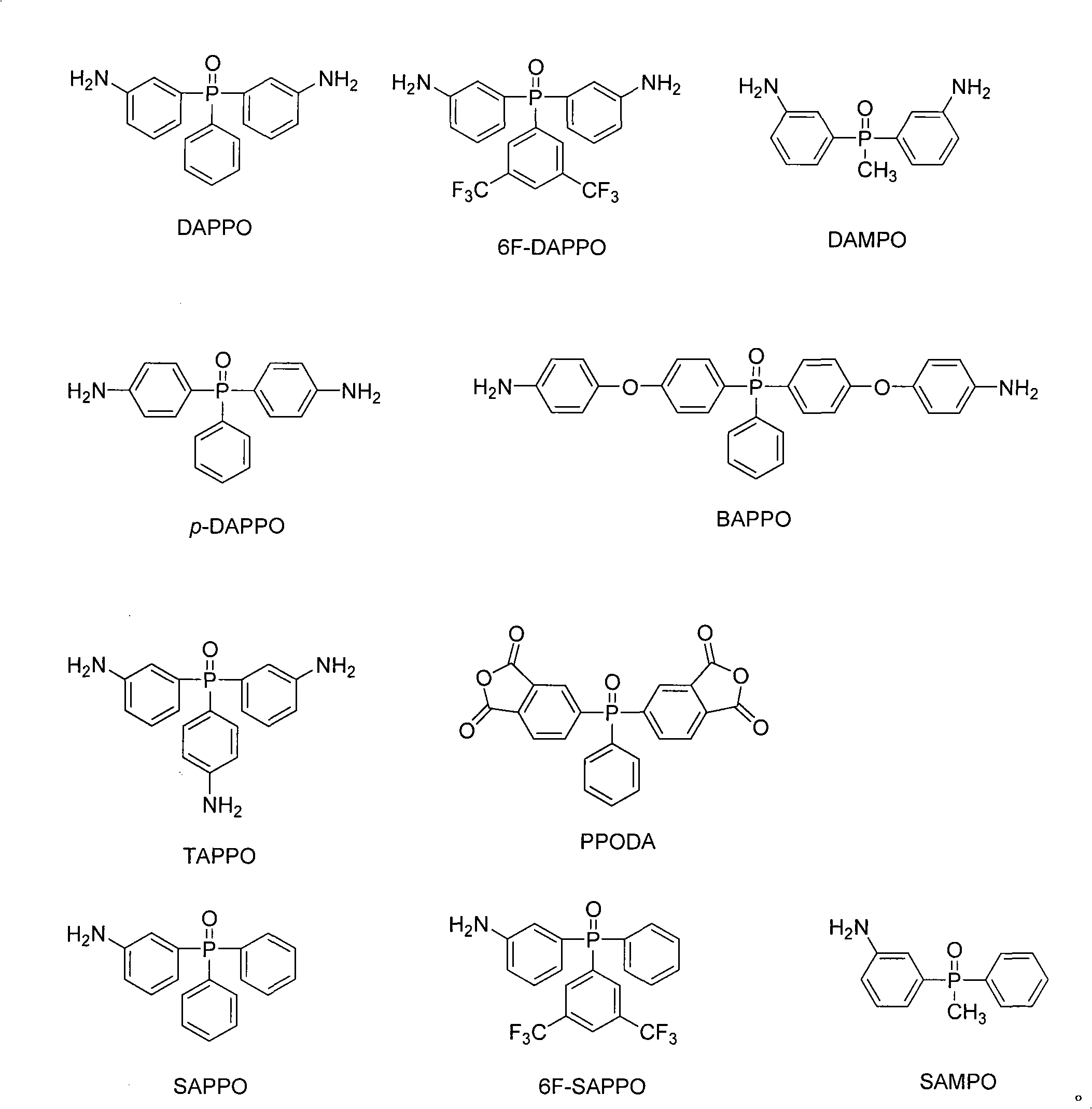

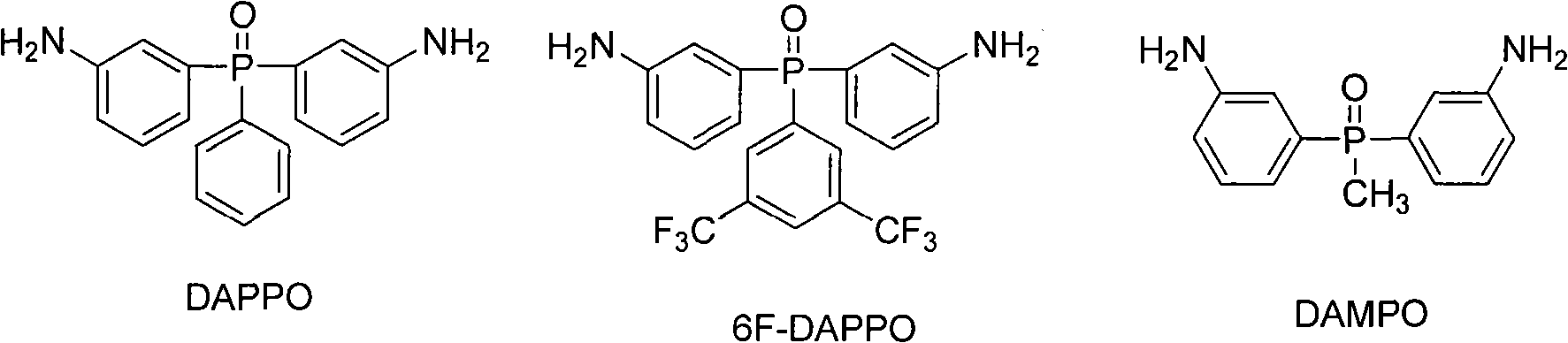

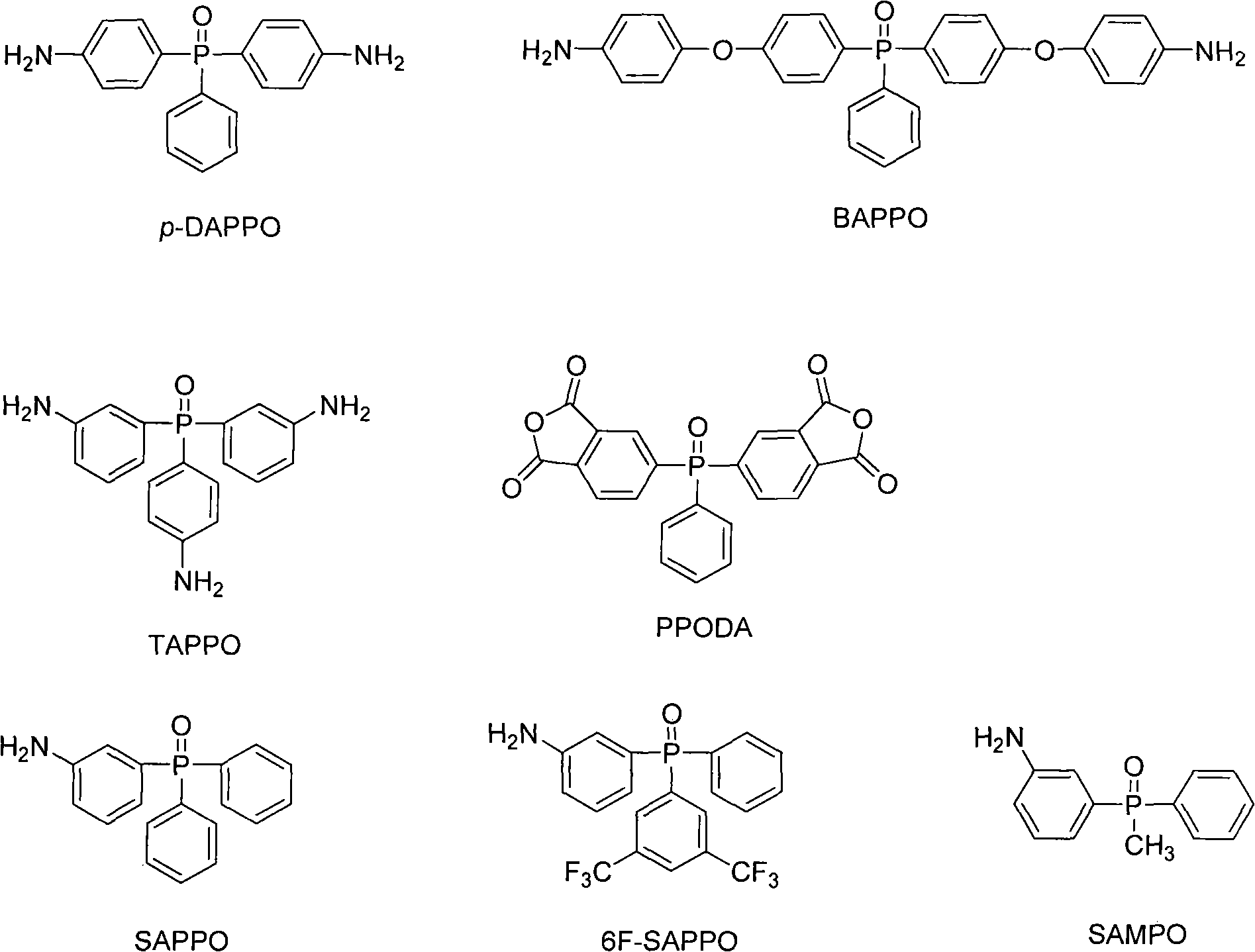

Method used

Image

Examples

Embodiment 1

[0019] At room temperature, in a three-necked bottle, first fully dissolve 30.83g of phosphorus-containing diamine monomer DAPPO in N,N'-dimethylacetamide (DMAc), and then add in batches when the solution is clear and no particles are seen. 3,3',4,4'-biphenyldianhydride (BPDA) with the amount of diamine and other substances. After stirring and reacting for about 4 hours, 22.1 g of tetraethyl orthosilicate (TEOS) was added as an inorganic component, and stirring was continued for 8 hours to obtain a uniform and viscous precursor polyamic acid (PAA) solution.

[0020] Apply the precursor solution to clean glass, scrape out a layer of liquid film about 0.25mm thick with a glass rod wrapped with copper wire, and place it horizontally in a far-infrared drying oven to achieve imide through temperature programming control. The heating program is: 60°C / 1h, 80°C / 1h, 120°C / 1h, 150°C / 1h, 200°C / 1h, 250°C / 1h, 300°C / 1h, after cooling to room temperature, the film is removed to obtain Polyi...

Embodiment 2

[0031] Change the quality of the inorganic component ethyl orthosilicate to 44.2g, and the others are the same as in Example 1.

Embodiment 3

[0033] Change the inorganic component into 19.3g tetra-n-butyl zirconia, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com