Method of preparing cerium oxide nano-plate

A nano-sheet, cerium oxide technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of reducing the specific surface area of cerium oxide, reducing the performance of cerium oxide, affecting the specific surface area, etc., and achieving easy control of the structure. , The effect of improving catalytic efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

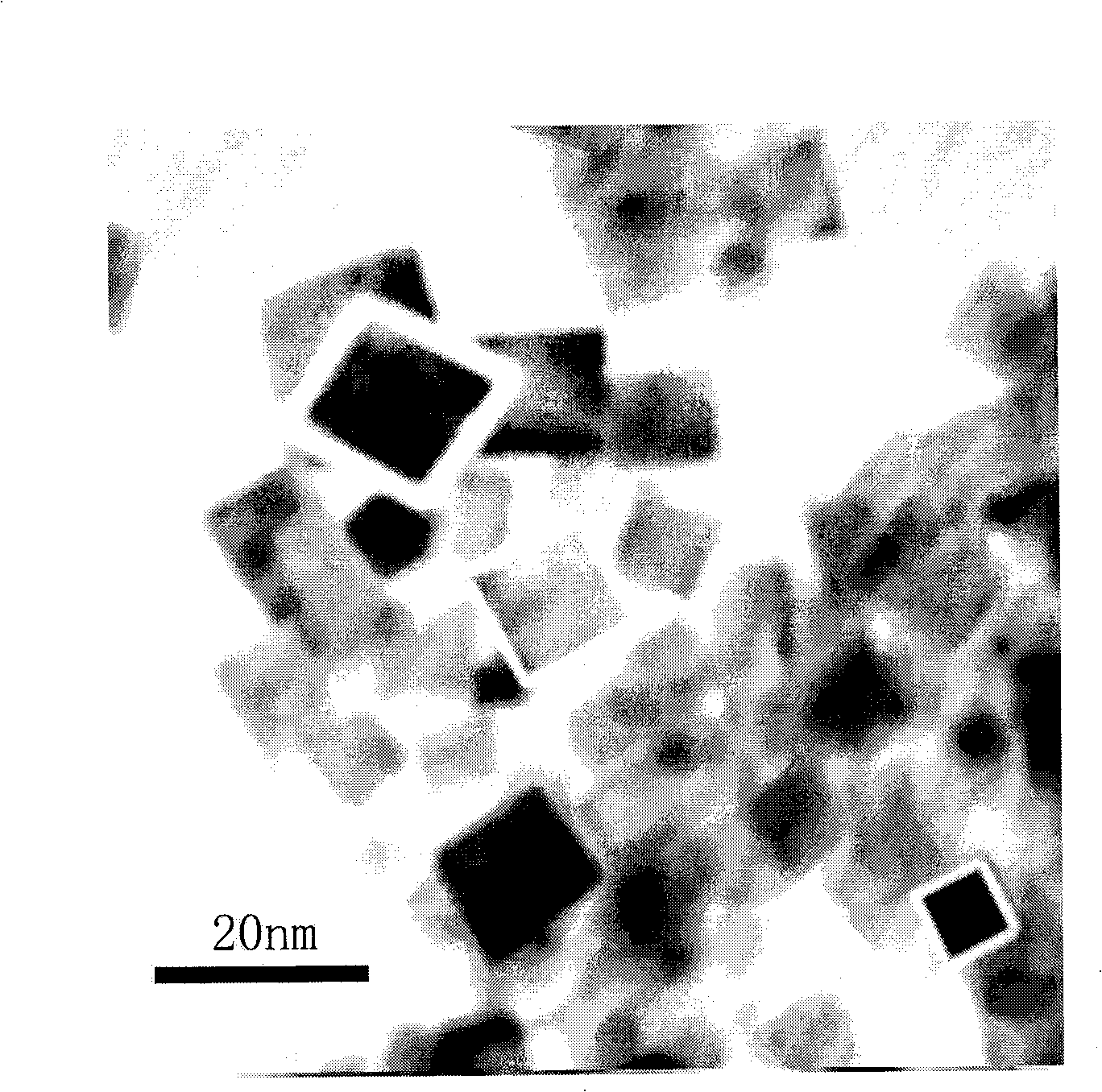

[0016] Example 1: With stirring, dissolve 1 mmol of cerium nitrate and 3 mmol of cetyltrimethylammonium bromide in 35 mL of water, add 5 mL of ammonia water, ultrasonicate for 10 min, transfer to a 50 mL hydrothermal kettle, and heat at 100 °C After hydrothermal heating for 24 hours, the product was centrifuged, washed with deionized water until neutral (pH 7), and dried at 60°C to obtain cerium oxide nanosheets. (The product is square with a size of 20-40 nm and a thickness of 3-5 nm).

Embodiment 2

[0017] Example 2: Dissolve 0.3mmol of cerium chloride and 0.9mmol of cetyltrimethylammonium bromide in 35mL of water, add 5ml of ammonia water, sonicate for 10min, transfer to a 50mL hydrothermal kettle, and heat at 180°C for 24h , the product was centrifuged, washed with deionized water until neutral (pH 7), and dried at 60°C to obtain cerium oxide nanosheets. (The product is rhombohedral and hexagonal, with a size of 10-20 nm and a thickness of 3-5 nm).

Embodiment 3

[0018] Example 3: Dissolve 0.3mmol of cerium ammonium nitrate and 0.9mmol of cetyltrimethylammonium bromide in 35mL of water, add 5ml of ammonia water, sonicate for 10min, transfer to a 50mL hydrothermal kettle, and heat at 120°C for 72h , the product was centrifuged, washed with deionized water until neutral (pH 7), and dried at 60°C to obtain cerium oxide nanosheets. (The products are square, rhombus and hexagonal, with a size of 40-80 nm and a thickness of 3-5 nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com