Method for treating papermaking waste water by constructing artificial flora

A technology of papermaking wastewater and bacterial colony, which is applied in the direction of processing wastewater treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as difficult to repeat and control, unclear treatment process, uncontrollability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The determination of each bacterial strain's growth demand for oxygen, temperature tolerance, pH and salinity tolerance

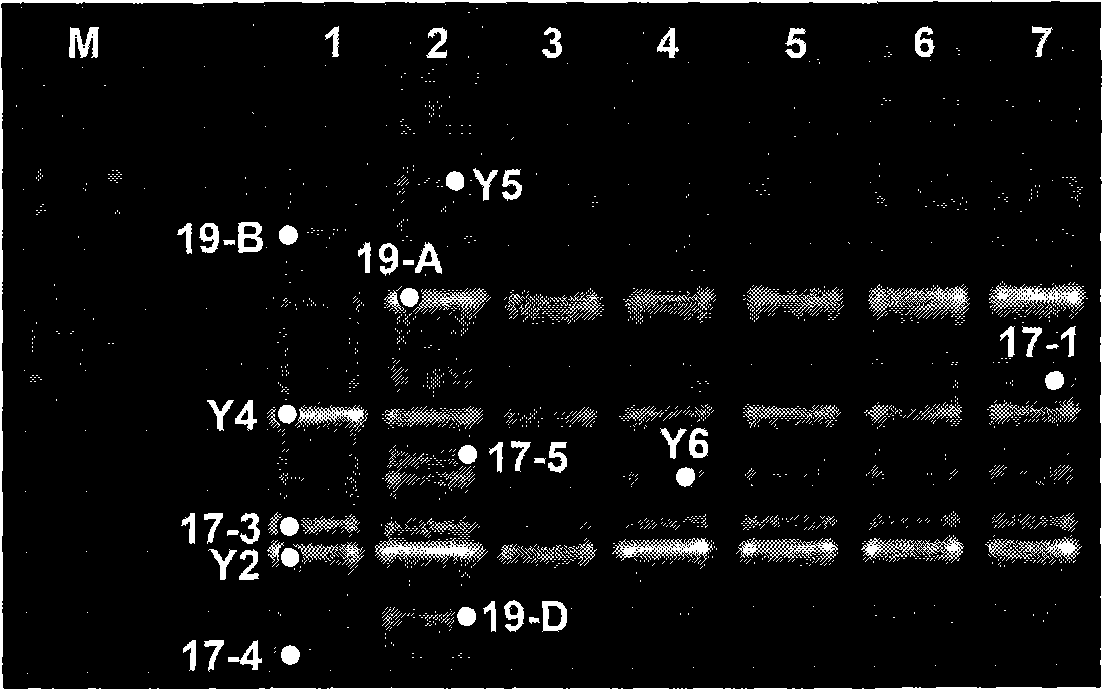

[0046](1) Strain selection: Four strains of Halomonas (Halomonas) isolated from various extreme natural environments such as strong alkali and high salinity and preserved in the "China Typical Culture Collection Center" were selected on October 29, 2008. ) sp.Y2 CCTCC NO: M 208188, Halomonas (Halomonas) sp.17-5 CCTCC NO: M 208192, Halomonas (Halomonas) sp.19-A CCTCC NO: M 208186 or Halomonas ( Halomonas) sp.19-D CCTCC NO: M 208193 and seven strains of Bacillus (Bacillus) sp.Y4 CCTCC NO: M 208189, Bacillus (Bacillus) sp.Y5CCTCC NO: M 208190, Bacillus (Bacillus) sp.17 -1 CCTCC NO: M 208183, Bacillus sp.17-3 CCTCC NO: M 208184, Bacillus sp.17-4 CCTCC NO: M 208185, Bacillus sp.19-B CCTCC NO: M 208187 or Bacillus sp.Y6 CCTCC NO: M 208191;

[0047] First, select the strains in the above-mentioned Halomonas sp.Y2, Halomonas sp.17-5, Halomona...

Embodiment 2

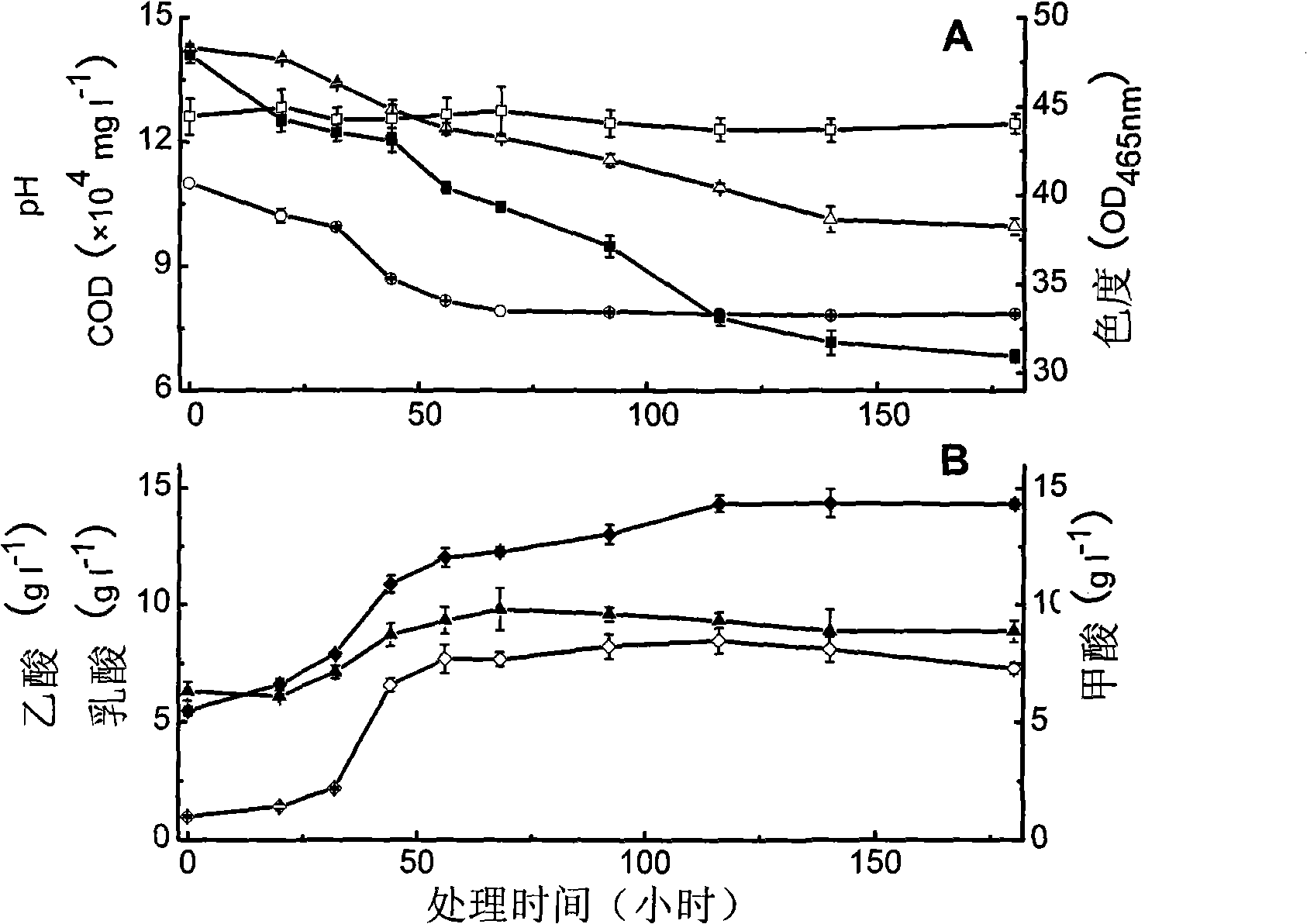

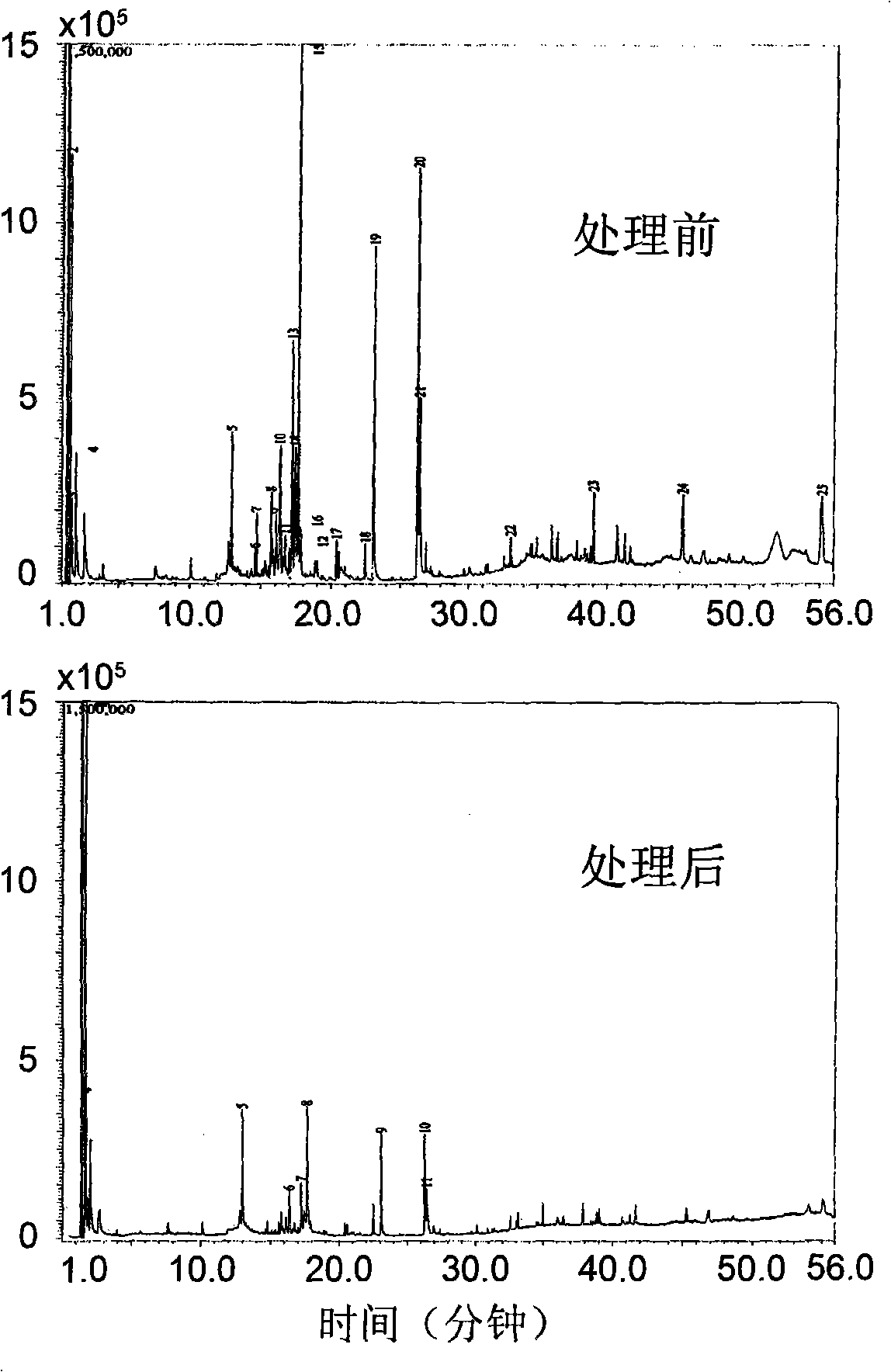

[0063] Embodiment 2: the method for constructing artificial flora to treat papermaking wastewater

[0064] Select Halomonas (Halomonas) sp.Y2CCTCC NO: M 208188 and Halomonas (Halomonas) sp.19-A CCTCC NO: M 208186 strains to carry out the following operations respectively:

[0065] (1) Slant culture: the above-mentioned Halomonas strain was inoculated on a solid slant medium containing 1.6% agar powder by mass percentage and a pH of 8.0, and the cells were cultured at 30° C. for 20 hours;

[0066] (2) First-level seed cultivation: the thallus cultivated in step (1) was put into 100ml complete liquid medium with an inoculation loop under aseptic conditions, and cultured on a shaker at 200 rpm for 16 hours at 30°C. Hours to the middle of the logarithmic growth phase, the first-class seeds were obtained;

[0067] (3) Expansion cultivation: with the inoculum size of 5% by volume ratio, connect the primary seeds in 1000ml complete liquid medium, shake and cultivate for 16 hours on ...

Embodiment 3

[0078] Embodiment 3: the method for constructing flora to carry out papermaking wastewater treatment

[0079] Select Halomonas sp.Y2 CCTCC NO: M 208188, Halomonas sp.17-5 CCTCC NO: M 208192 and Halomonas sp.19-A CCTCC NO: The M 208186 strain was subjected to the following operations:

[0080] (1) Slant culture: the above-mentioned Halomonas strain was inoculated on a solid slant medium containing 1.6% agar powder by mass percentage and a pH of 8.0, and the cells were cultured at 30° C. for 20 hours;

[0081] (2) First-level seed cultivation: the thallus cultivated in step (1) was put into 100ml complete liquid medium with an inoculation loop under aseptic conditions, and cultured on a shaker at 200 rpm for 16 hours at 30°C. Hours to the middle of the logarithmic growth phase, the first-class seeds were obtained;

[0082] (3) Expansion cultivation: with the inoculum size of 5% by volume ratio, connect the primary seeds in 1000ml complete liquid medium, shake and cultivate for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com