Adhesive complex tunnel fire-resisting paint

A technology of fire retardant coatings and binders, applied in fire retardant coatings, cement coatings, etc., can solve the problems of high alumina cement cost, unfavorable use of large-scale tunnel fire retardant coatings, etc., to improve the fire resistance limit, reduce heat conduction, reduce The effect of the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

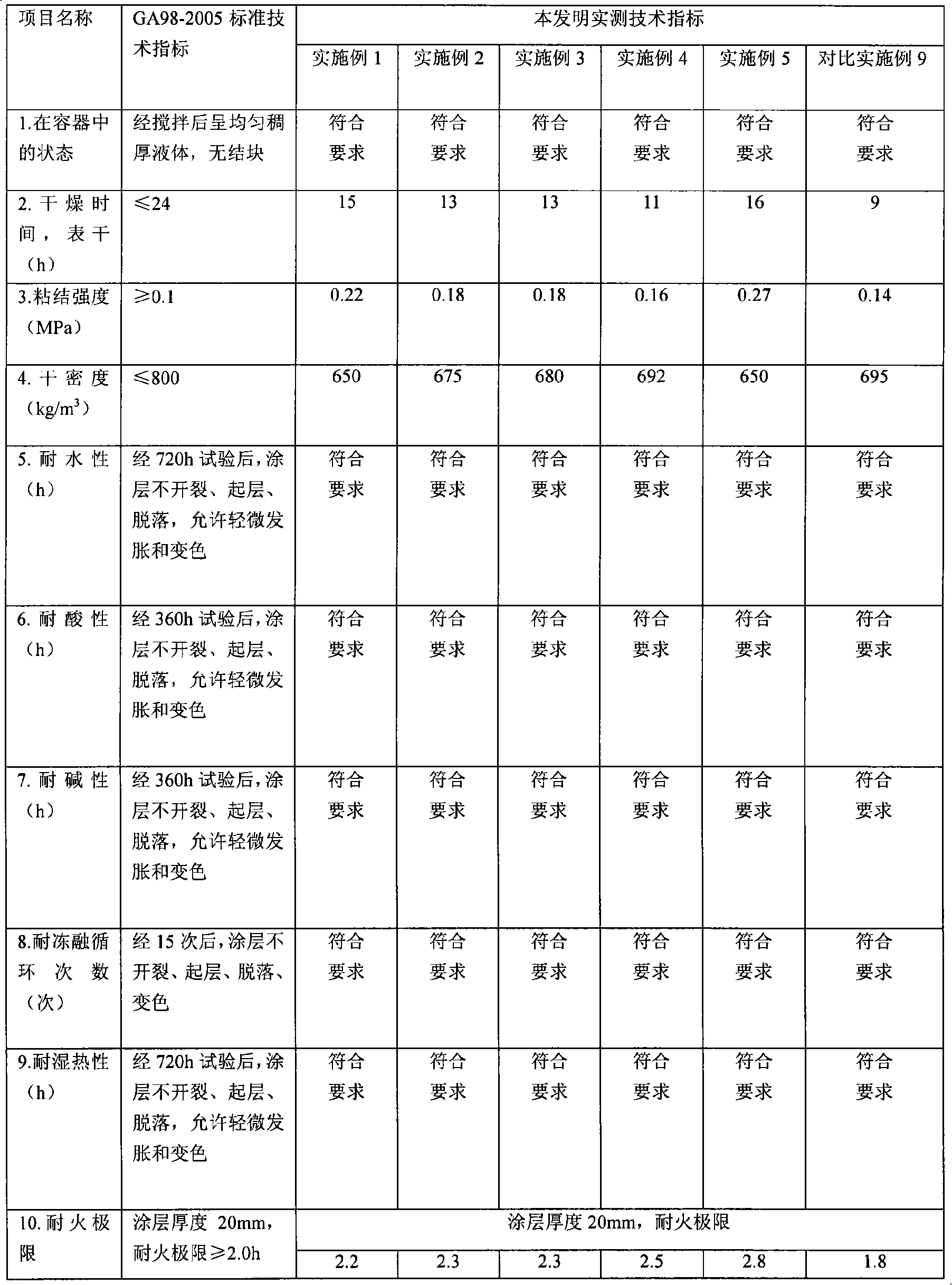

Embodiment 1

[0020] Ordinary Portland cement and high alumina cement (weight ratio: 1:1) 10 kg; expanded perlite, expanded vermiculite and light calcium carbonate (weight ratio: 3:1:1) 50 kg; inorganic mineral fiber 1 kg; 30 kg of magnesium hydroxide and aluminum hydroxide (weight ratio: 3:1); 3 kg of rubber powder; 1.0 kg of superplasticizer, air-entraining agent and expansion agent (weight ratio: 12:1:2). Put the above-mentioned raw materials into a forced mixer and stir evenly. At the construction site, add water according to the weight of the material (the weight ratio of material to water is 1:1), stir it with a forced mixer for 15 minutes, mix it into a mortar with a certain consistency, spray it on the surface of the substrate that has been properly treated, and maintain it at room temperature for 28 days. test.

Embodiment 2

[0022] Ordinary Portland cement and high alumina cement (weight ratio 1:2) 35 kg; expanded perlite, expanded vermiculite and light calcium carbonate (weight ratio 3:2:1) 90 kg; inorganic mineral fiber 4 kg; hydrogen Magnesium oxide and aluminum hydroxide (weight ratio 2:1) 10 kg; rubber powder 5 kg; superplasticizer, air-entraining agent and expansion agent (weight ratio 5:1:1) 3.0 kg. Put the above-mentioned raw materials into a forced mixer and stir evenly. At the construction site, add water according to the weight of the material (the weight ratio is 1:1.5), stir it with a forced mixer for 15 minutes, mix it into a mortar with a certain consistency, spray it on the surface of the substrate that has been properly treated, and test it after 28 days of curing at room temperature.

Embodiment 3

[0024] Ordinary Portland cement and high alumina cement (weight ratio 1:3) 50 kg; expanded perlite, expanded vermiculite and light calcium carbonate (weight ratio 4:2:1) 40 kg; inorganic mineral fiber 10 kg; hydrogen Magnesium oxide and aluminum hydroxide flame retardant system (weight ratio 3.5:1) 5 kg; rubber powder 0.1 kg; high-efficiency water reducer, air-entraining agent and expansion agent (weight ratio 10:1:3) 0.5 kg. Put the above-mentioned raw materials into a forced mixer and stir evenly. At the construction site, add water according to the weight percentage of the material (weight ratio 1:0.8), stir with a forced mixer for 15 minutes, mix it into a mortar with a certain consistency, spray it on the surface of the substrate that has been properly treated, and test it after 28 days of curing at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com