Process for producing carboxylic acid

A carboxylic acid and preparatory process technology, applied in the field of carboxylic acid preparation, can solve the problems of increased heat removal load on the cooling surface, reduced cooling surface area, and difficulty in high-speed operation of the scraping device, and achieves high productivity and excellent cleaning performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The method for producing carboxylic acid of the present invention has a preparatory step before the crystallization step in which carboxylic acid crystals are precipitated from a carboxylic acid-containing liquid in a crystallization tank. Cool to below the crystallization onset temperature.

[0037] The carboxylic acid-containing liquid is not limited as long as it contains at least carboxylic acid and crystallizes carboxylic acid by lowering the temperature. It may be liquid carboxylic acid itself or a liquid in which carboxylic acid is dissolved in a solvent. Specifically, a liquid in which carboxylic acid is dissolved in a solvent to be purified, a liquid containing carboxylic acid (mother liquor) obtained in a carboxylic acid production process, a mother liquor after separating a part of carboxylic acid crystals, melting of carboxylic acid crystals, etc. Liquid, etc., can also be any processed liquid.

[0038] The type of carboxylic acid is not particularly limite...

Embodiment 1

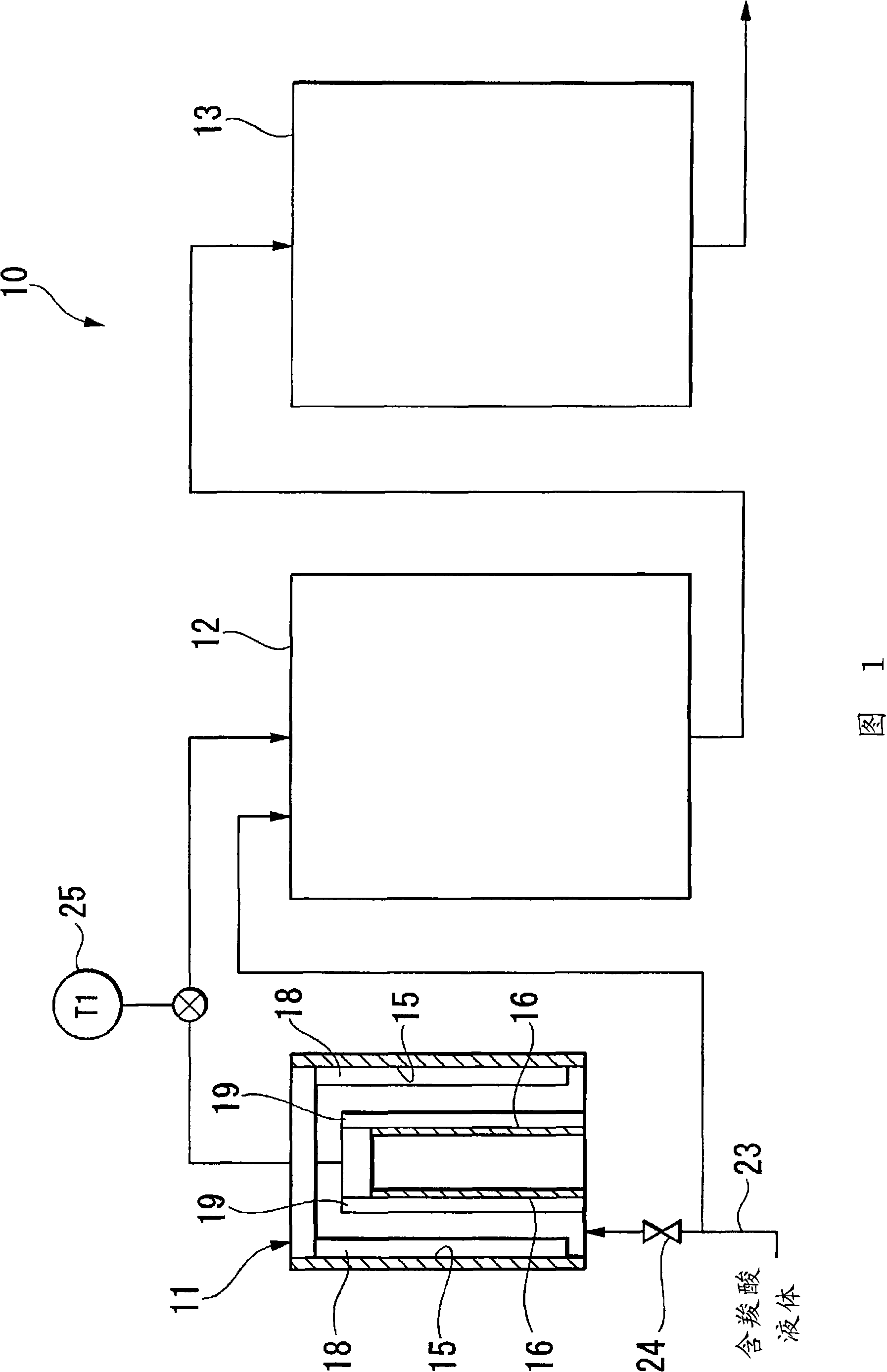

[0080] Using the apparatus shown in FIG. 1, the crystallization step and the preliminary step were performed.

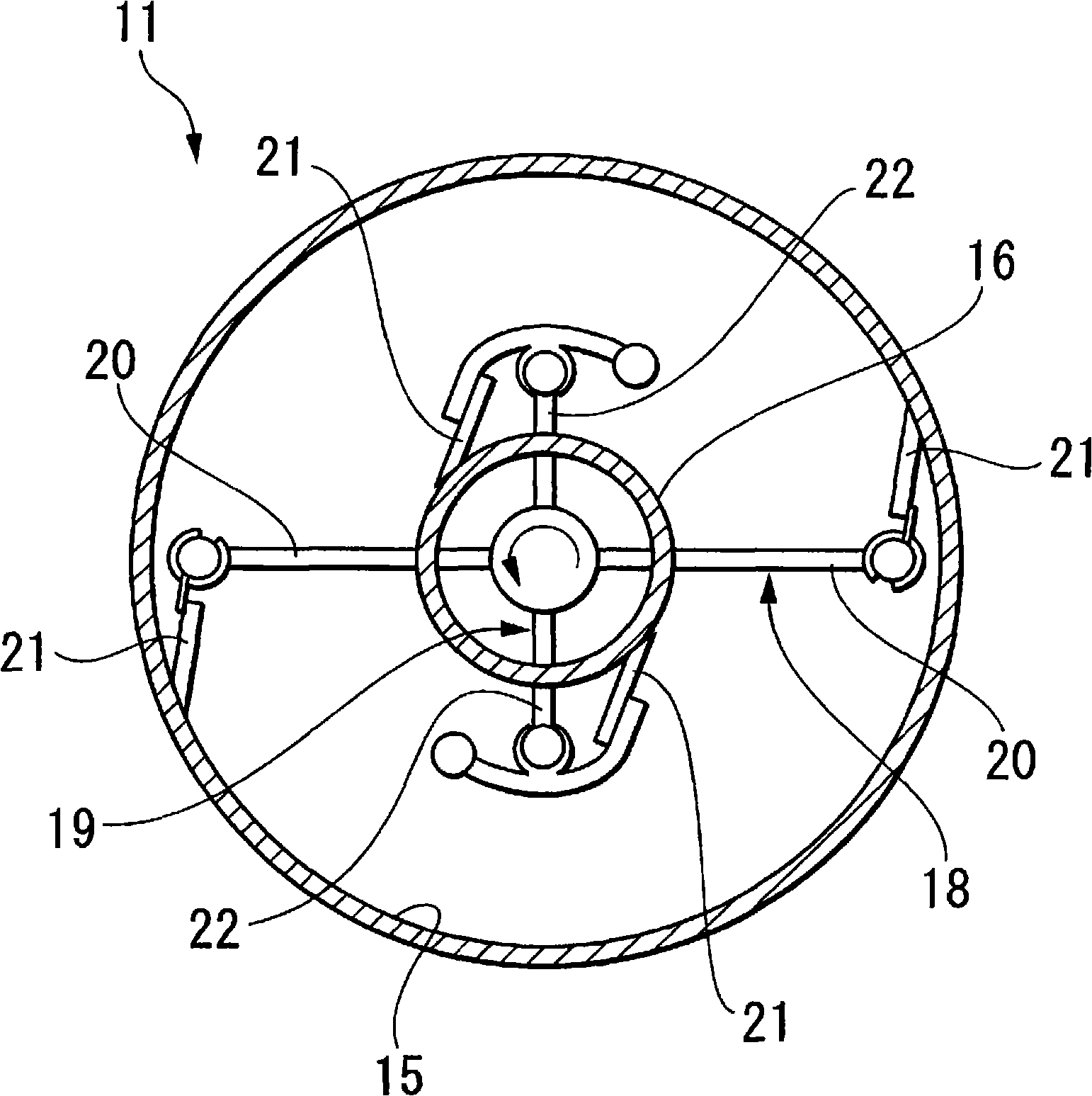

[0081] In the cooler 11, "Tarosamu (trade name, manufactured by N.V. Machinefabriek Terlet Co.)" was used as a double cylindrical scraped surface heat exchanger. This heat exchanger has two sets of scraping parts 20 and 22 each having a scraper (10 mm thick, made of PTFE) 21 as an outer cylinder side scraper device 18 and an inner cylinder side scraper device 19 .

[0082] On the side of the rear stage of the cooler 11, a first crystallization tank 12 and a second crystallization tank 13 each having scraper blades are arranged in series. The volume of the cooler 11 is 0.16% of the total volume of the first crystallization tank 12 and the second crystallization tank 13 .

[0083] First, in the crystallization tanks 12 and 13, add a carboxylic acid-containing liquid (by mixing 4 mass % methanol in methacrylic acid, adjust to a freezing point (crystallization start tem...

Embodiment 2

[0090] The device was operated in the same manner as in Example 1, except that the scraper 21 included in the scraper device 19 on the inner cylinder side and the scraper device 18 on the outer cylinder side was changed to a scraper made of phenolic resin (bakelite) having a thickness of 3.5 mm.

[0091] As a result, a slurry-like carboxylic acid-containing liquid having a cooler outlet temperature of 8.0° C. and containing 8.9% by mass of methacrylic acid crystal particles having a particle diameter of about 80 μm was continuously discharged from the cooler 11 . When this operation was continued, the operation status was also stable after 100 hours, and a slurry-like carboxylic acid-containing liquid containing 37% by mass of methacrylic acid crystal particles with a particle diameter of about 225 μm was obtained from the outlet of the second crystallization tank 13 .

[0092] In addition, at this time, the heat removal load of the first crystallization tank 12 is 6.0MJ / hr / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com