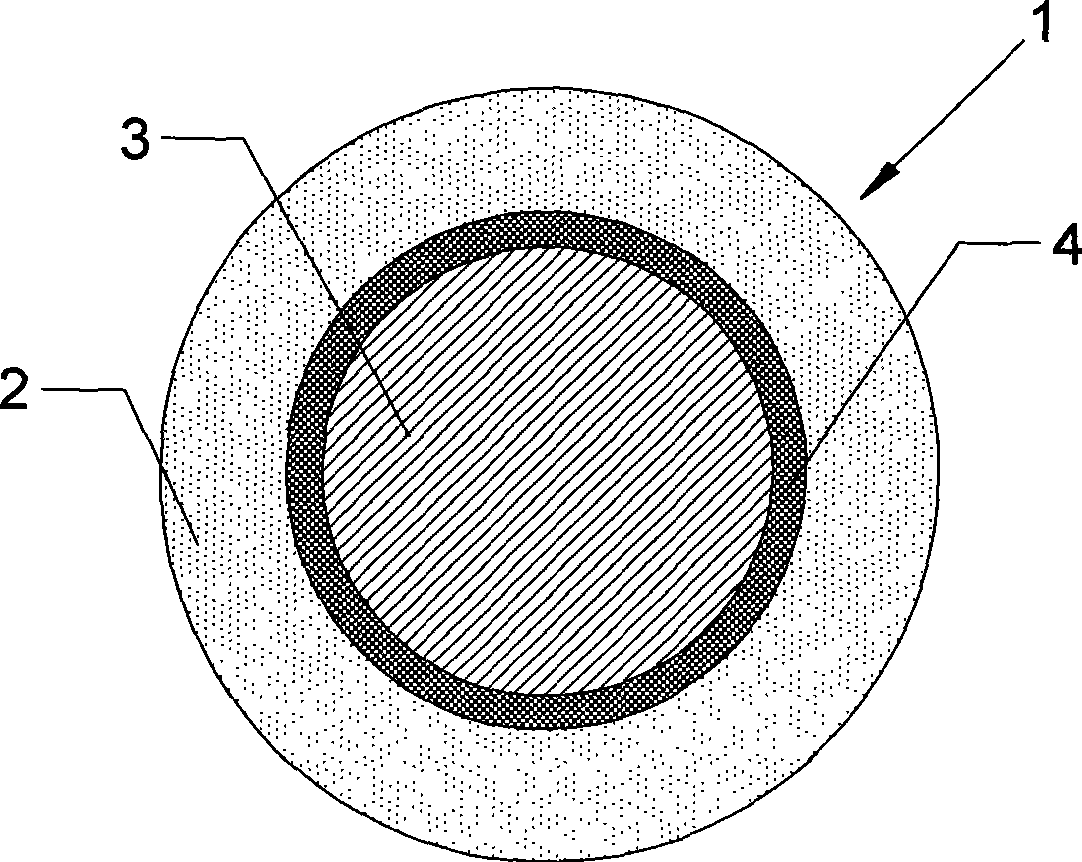

Vascular undercoat stent

An inner coating and blood vessel technology, applied in stents, coatings, medical science, etc., to achieve the effect of no cracking, good compatibility, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Figure 4 It is a schematic diagram of the preparation process of the intravascular coated stent of the present invention. As can be seen:

[0060] The preparation method of endovascular coated stent of the present invention comprises the following steps:

[0061] (1) coating and forming a polymer bottom layer on the surface of the stent body;

[0062] (2) Alternate coating on the surface of the polymer bottom layer to form multiple silk fibroin peptide layers and chitosan layers.

[0063] The coating comprises a polymer bottom layer, a multi-layer silk fibroin peptide layer and a chitosan layer.

[0064] In the above-mentioned preparation method, when the polymer bottom layer is coated on the surface of the stent body, the solution used is an aqueous solution of NaCl containing polyethyleneimine, wherein the concentration of polyethyleneimine is 5-10mg / ml, and the soaking time is 10 -60 minutes.

[0065] In the above-mentioned preparation method, when the silk fib...

Embodiment 1

[0085] Example 1 Hydrophilicity experiment of the intravascular coated stent of the present invention

[0086] Experimental instrument: The contact angle of the coating surface was measured by an OCA20 video optical contact angle measuring instrument (manufactured by Dataphysics Instrument Company, Germany). Measurement accuracy: ±0.1°.

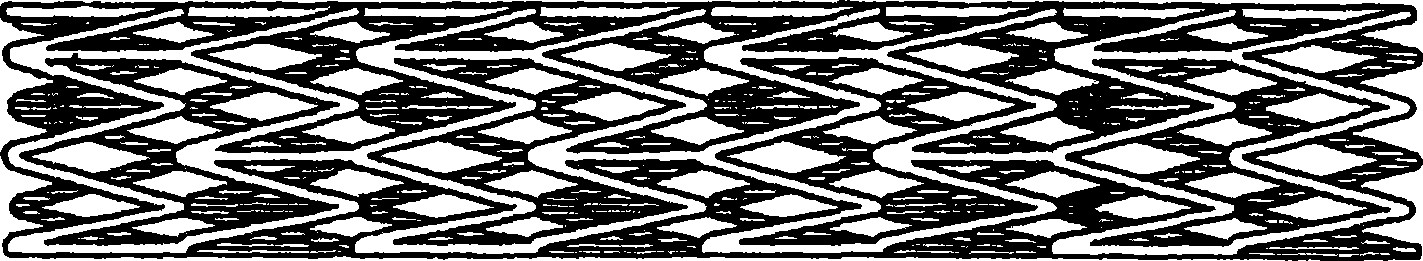

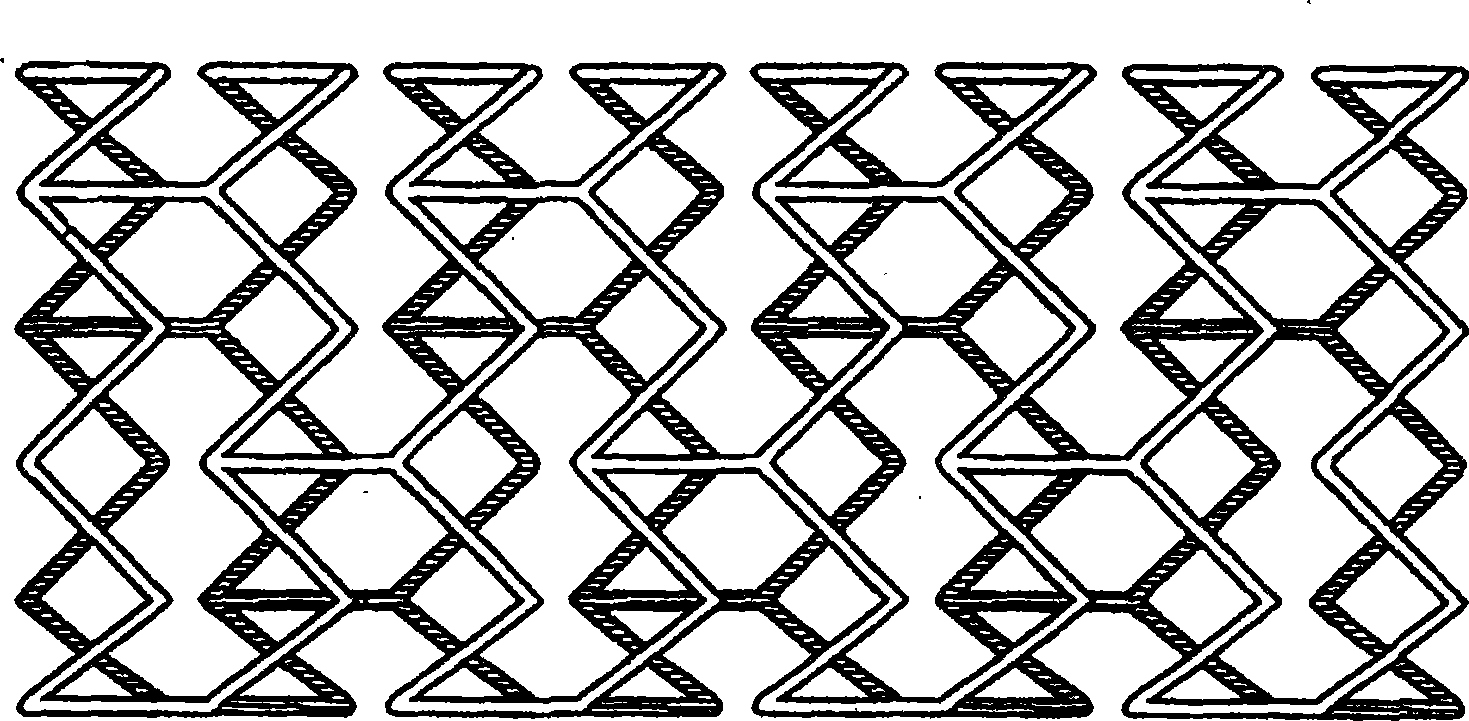

[0087] Experimental material: 316L stainless steel was used as the support body, and 12 pieces of coated supports were prepared by using the above-mentioned electrostatic self-assembly method of the present invention. The first layer of coating is composed of polyethyleneimine layer and 1 layer of silk peptide layer; the second layer of coating is polyethyleneimine layer, 1 layer of silk peptide layer and 1 layer of chitosan from inside to outside Layer composition; the third layer of coating is polyethyleneimine layer, (silk fibroin peptide layer + chitosan layer) from the inside to the outside 1 +Silk fibroin peptide layer; the fourth lay...

Embodiment 2

[0090] Example 2 Anticoagulant effect experiment of endovascular coated stent of the present invention

[0091] Experimental materials: 6 pieces of 316L stainless steel endovascular coated stents prepared according to the above-mentioned electrostatic self-assembly method of the present invention (1 layer of polyethyleneimine layer, 21 layers of multi-layer silk fibroin peptide layer and chitosan layer) and only the surface Clean 6 pieces of uncoated 316L stainless steel brackets.

[0092] Experimental method: drop 0.1ml of anticoagulated human blood on the surface of the stent, add 0.01ml of CaCl with a micro-sampler 2 Solution (0.2mol / l), gently stir with a micro-syringe needle, and immediately record the time, at 10, 20, 30, 40, 50, 60min, wash with 50ml of distilled water respectively, collect the washing liquid in a beaker, and use 756MC The absorbance OD-time curve was tested at a wavelength of 540nm by an ultraviolet spectrophotometer, and compared with the uncoated 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com