Method for producing methane from smooth cord-grass and cattle manure

A technology of Spartina alterniflora and biogas production, which is applied in fermentation, biosynthesis, waste fuel, etc., to achieve the effects of strong operability, resource utilization, and improved buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

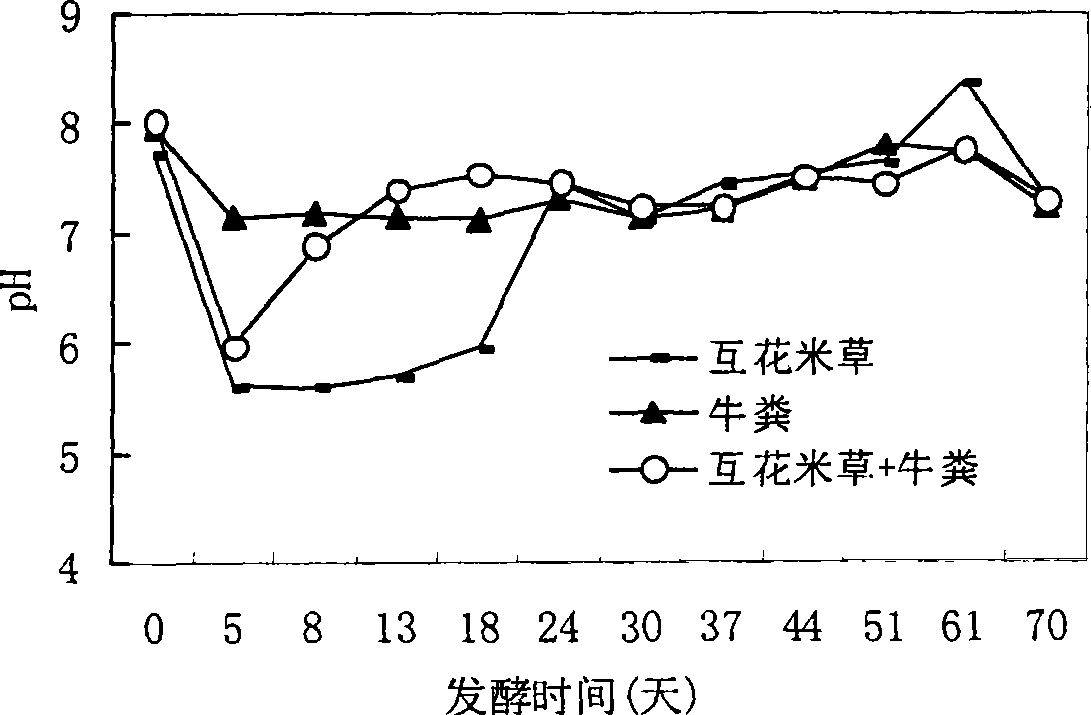

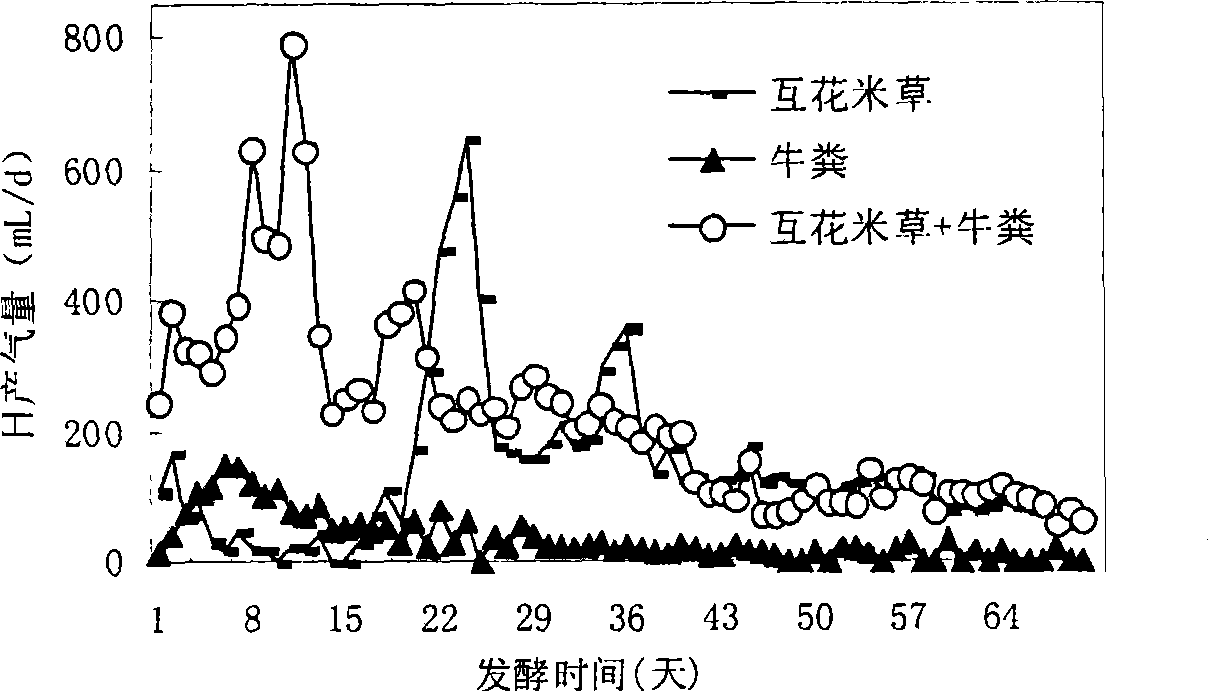

[0025] The anaerobic fermentation of Spartina alterniflora and cow manure produces biogas.

[0026] (1) Grinding pretreatment of the raw material Spartina alterniflora: cut the upper part of the harvested Spartina alterniflora by mechanical or manual methods (because the underground part is time-consuming and laborious to harvest, only the above-ground part can be harvested) into 1~2cm Of

[0027] (2) Adjust the solid content of cow dung to 10% with water and stir it;

[0028] (3) Mix the chopped Spartina alterniflora in step (1) with the cow dung processed in step (2) according to a dry matter mass ratio of 3:1;

[0029] (4) Separate the Spartina alterniflora (containing 42 grams of dry matter) obtained in step (1), the cow dung (containing 14 grams of dry matter) obtained in step (2), and the mixture (containing 56 grams of dry matter) obtained in step (3). Add to the 1000mL anaerobic reactor, add 96.68% water content of anaerobic sludge (one or more of the biogas residue from t...

Embodiment 2

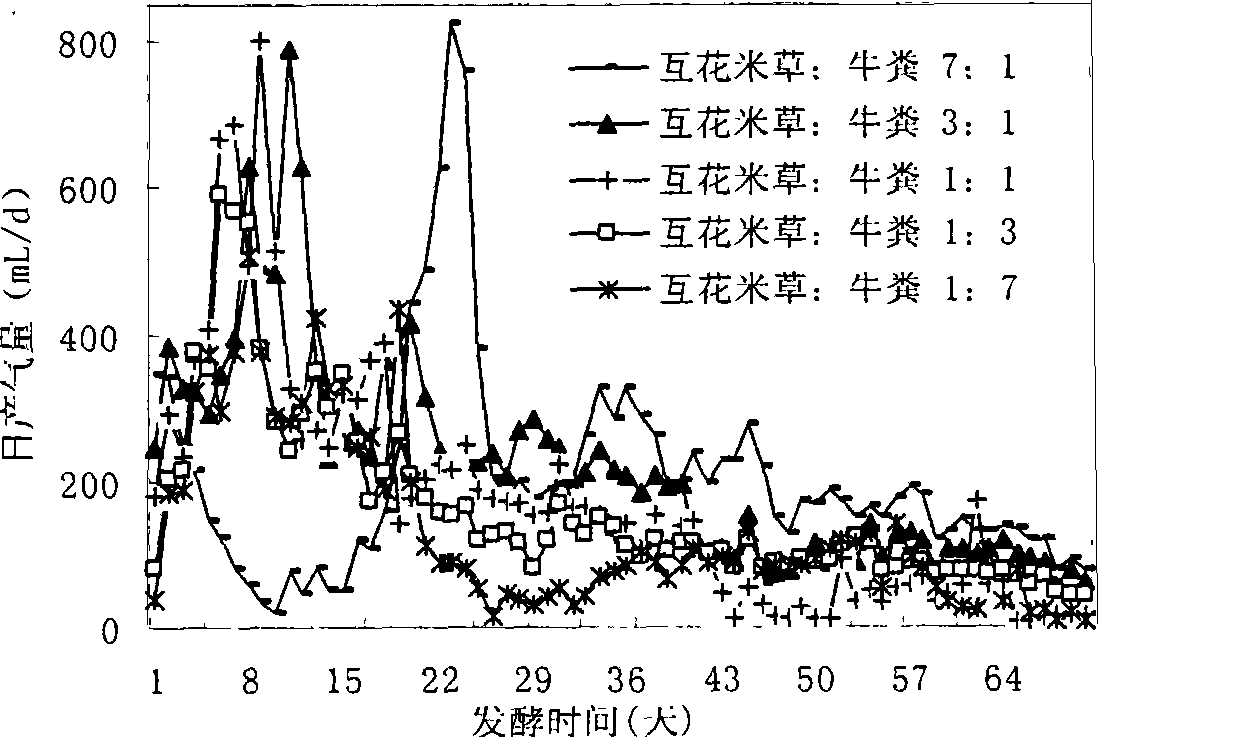

[0034] Spartina alterniflora and cow dung are mixed with different ratios to produce biogas by anaerobic digestion.

[0035] (1) The raw material Spartina alterniflora is crushed and pretreated by mechanically or artificially cutting the upper part of the harvested Spartina alterniflora into small sections of 1 to 2 cm;

[0036] (2) Adjust the solid content of the retrieved cow dung to 10% with water and stir it evenly;

[0037] (3) Combine the chopped Spartina alterniflora in step (1) with the cow dung pretreated in step (2) at a dry matter ratio of 7:1, 3:1, 1:1, 1:3, and 1: 7 Mix well;

[0038] (4) Add the mixture (containing 56 grams of dry matter) obtained in step (3) to a 1000 mL anaerobic reactor, add 371.30 grams of anaerobic sludge with a water content of 96.68% for inoculation and mix;

[0039] (5) Add water to the mixture obtained in step (4) to make the system TS load of the reactor 7%;

[0040] (6) Closed fermentation device, the gas outlet of the fermentation device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com