Automatic drip model method of microcomputer combining with digital control drip model machine

A technology of drip molding machine and microcomputer, applied in computer control, program control, comprehensive factory control, etc., can solve the problems of low precision, poor consistency, and low processing efficiency, so as to improve processing accuracy and optimize processing effect, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

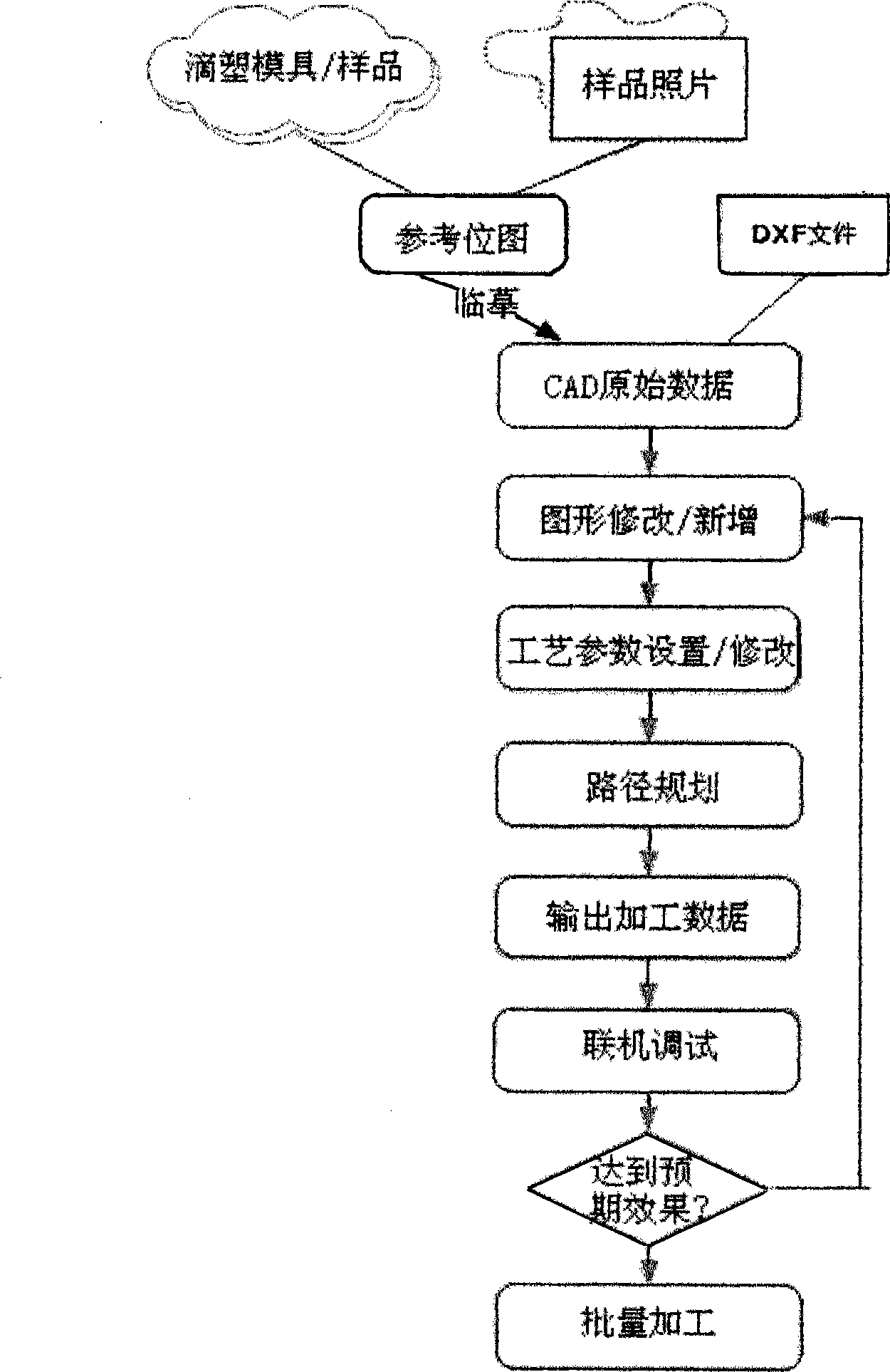

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] Prepare at least one set of CNC plastic dropping machines that can accept CNC instructions, such as WLZDH D541-8B plastic dropping machines from Ningbo Micro Automation Technology Co., Ltd., PTC RD441DS plastic dropping machines from Shanghai Baoling Electronic Technology Co., Ltd., Shishi Hengshun Machinery The factory's HS-DJ5880 plastic drop machine, the control system of this type of CNC plastic drop machine has "single-step" and "simulation" processing functions, and can perform parameter modification, starting point correction and other operations on the processing file, and has TCF Or the recognition ability of CNC instructions, which can convert the recognized instructions into the machining process of the actuator.

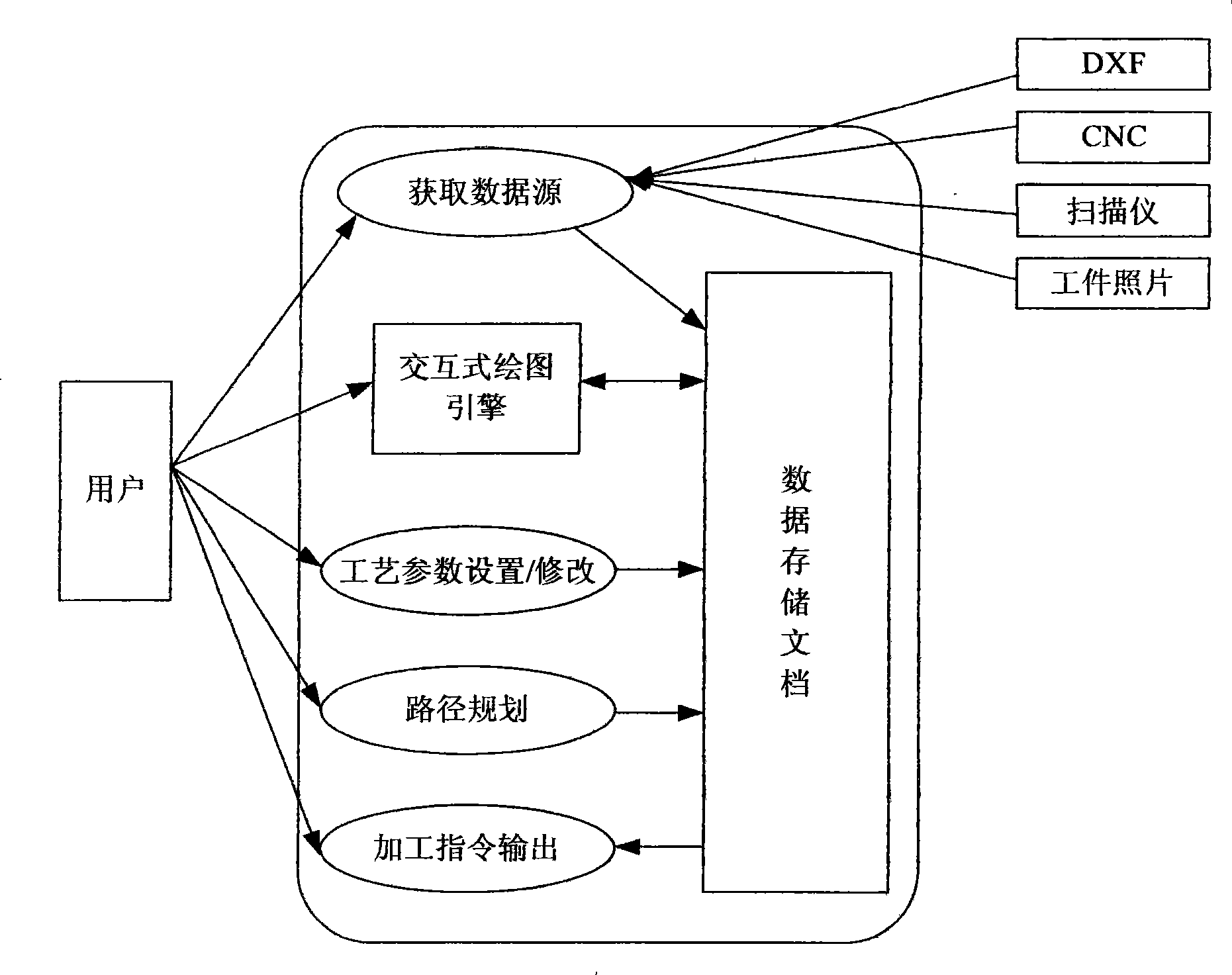

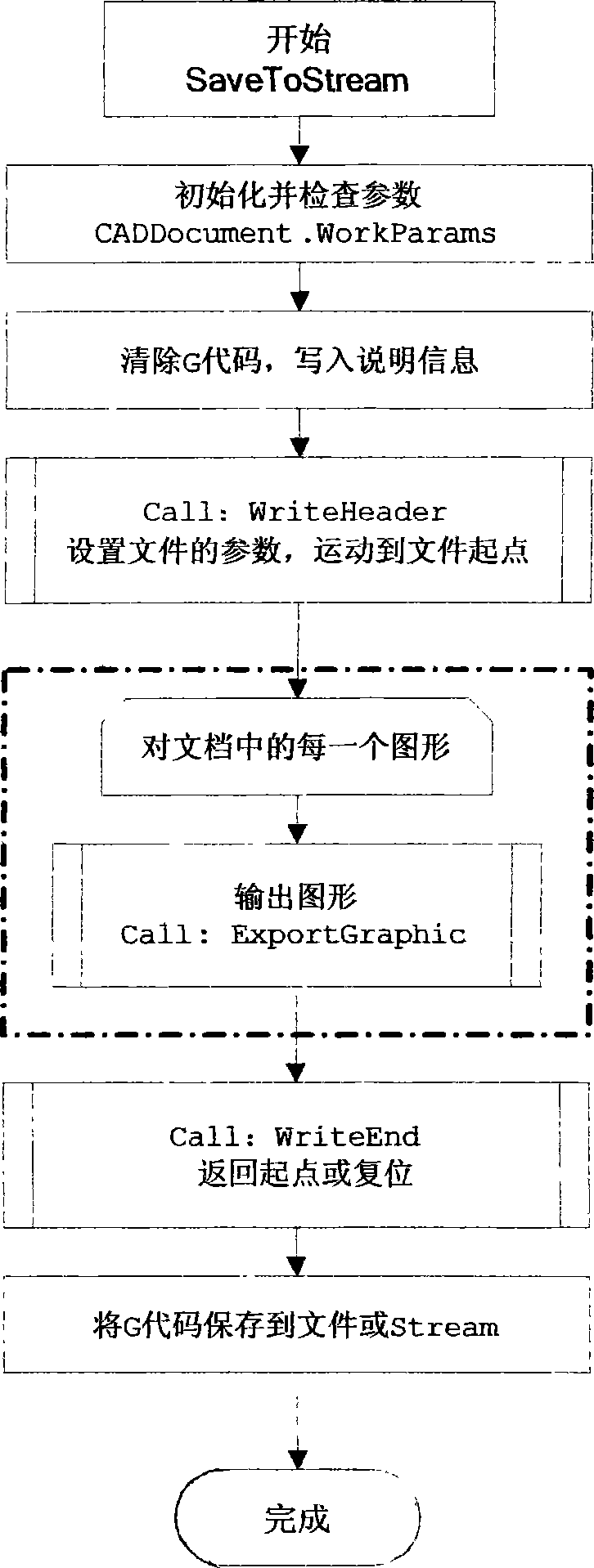

[0028] Embed processing programs based on various knowledge and algorithms of graphics and computational geometry in the microcomputer. The pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com