Method for removing vanadium impurity in titanic chloride by forced assisted-circulation heating

A technology of titanium tetrachloride and crude titanium tetrachloride, applied in titanium halide, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of scaling or scarring, affecting heating efficiency, air pollution, etc., to prevent The effect of volatilization, improving heating efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

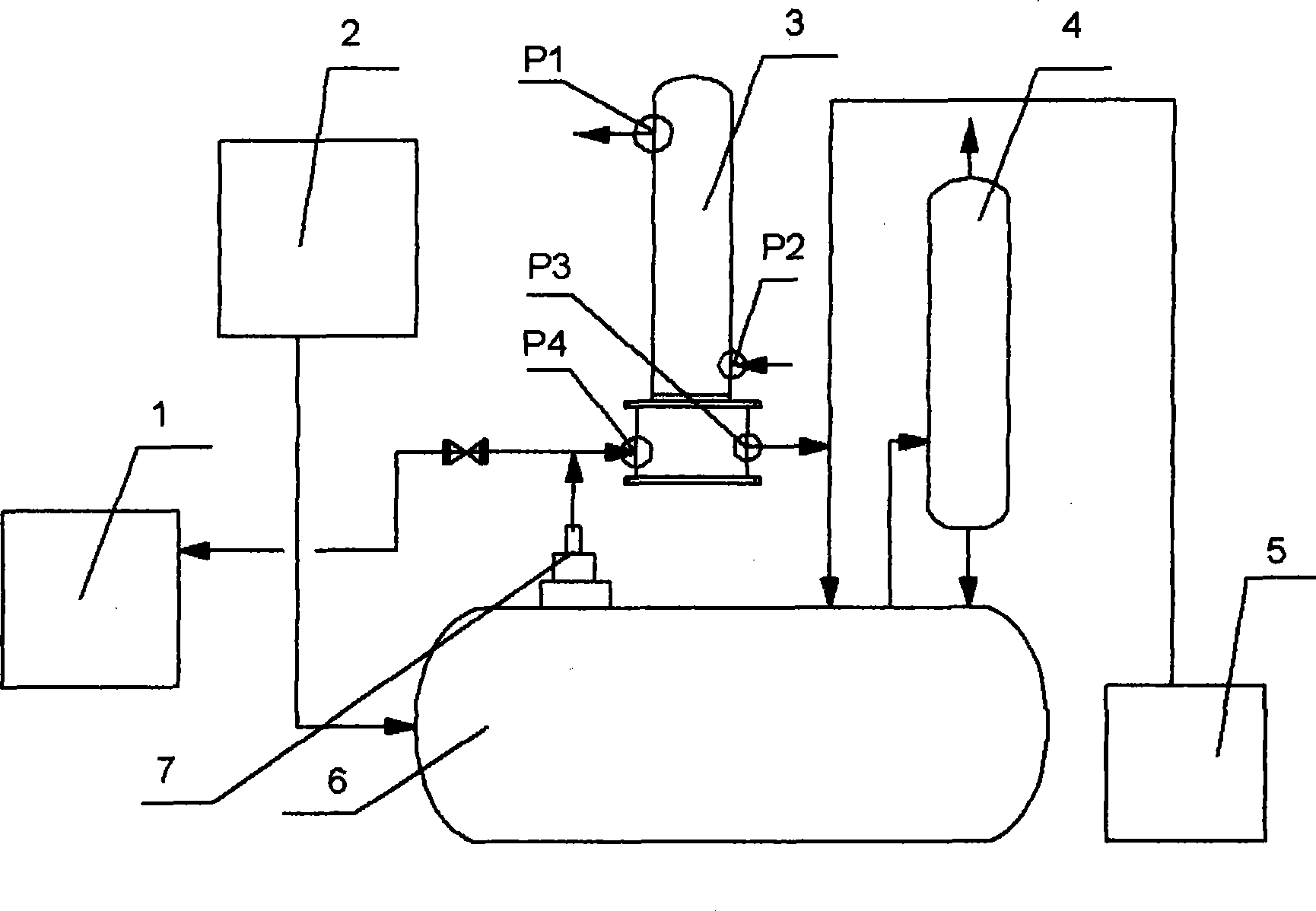

[0011] Embodiments are described below with reference to the drawings.

[0012] It is an equipment for forced external circulation heating to remove vanadium impurities in titanium tetrachloride. It connects the crude titanium tetrachloride storage tank 2 with the vanadium removal reaction evaporator 6 through the pipeline, and the vanadium removal reaction evaporator 6 is equipped with submerged mud The outlet of the pump 7 and the submerged mud pump 7 is connected to the tube side inlet P4 of the tubular heat exchanger 3, and the tube side outlet P3 of the heat exchanger 3 is connected to the vanadium removal reaction evaporator 6, and the vanadium removal reaction evaporator 6 passes through the pipeline Connected to the middle of the vanadium removal tower 4, the top of the vanadium removal tower 4 has a vent hole, and the bottom has a pipeline connected to the vanadium removal reaction evaporator 6, the mineral oil storage tank 5 is connected to the vanadium removal reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com