Method for preparing silica gel surface phenols molecularly imprinted polymer

A technology of molecular imprinting and polymers, applied in chemical instruments and methods, and other chemical processes, can solve the problems of low molecular weight of functional macromolecules, low grafting rate of imprinted materials, and low content of functional groups, etc., and achieve excellent adsorption options properties, easy adsorption equilibrium, and low diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

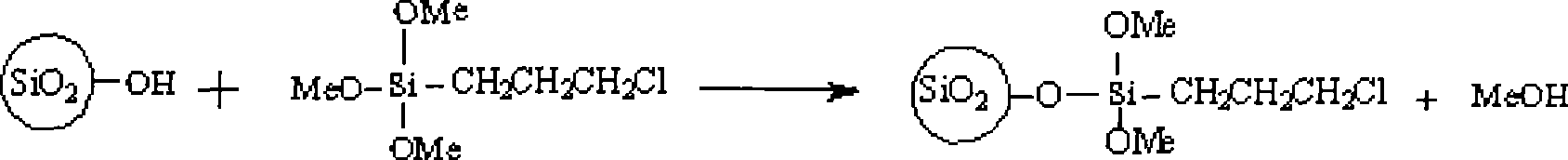

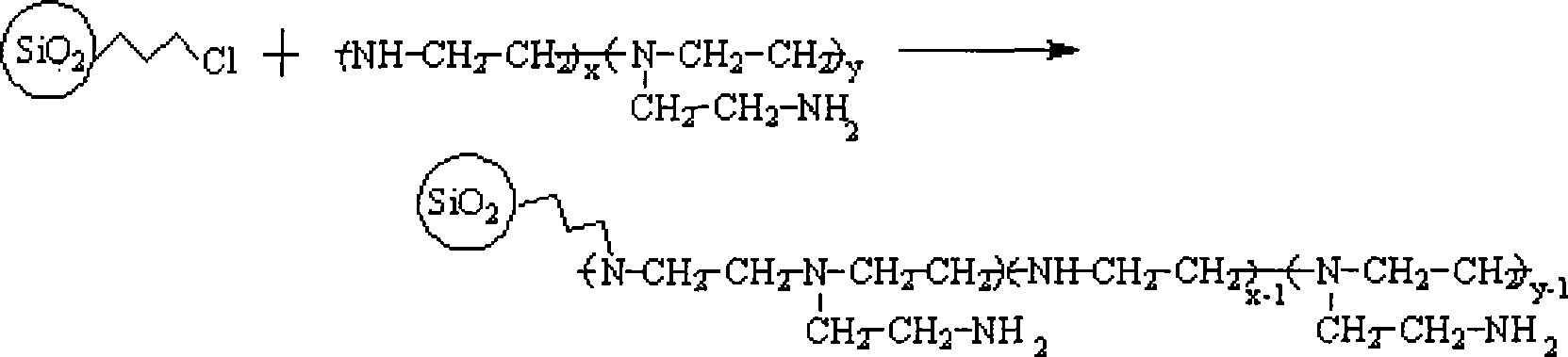

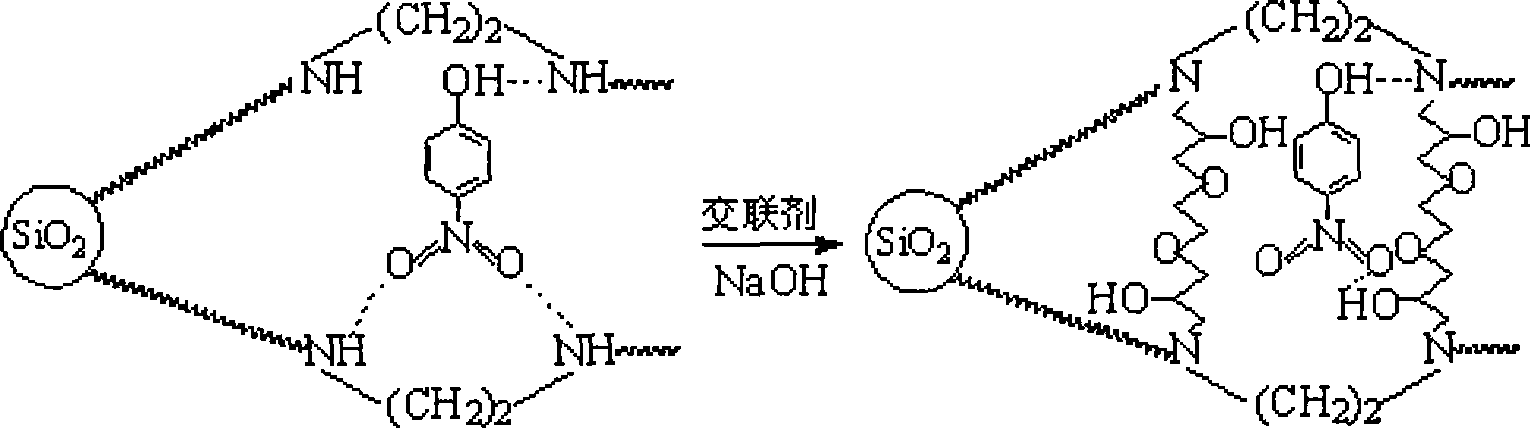

[0021] A method for preparing a phenolic molecularly imprinted polymer on the surface of silica gel, comprising the following steps: (1) Activation of silica gel: adding 5 g of silica gel to 30 mL of 5% hydrochloric acid aqueous solution, stirring and activating at 90° C., after 4 hours of activation , filter, fully wash the filter cake with distilled water, and finally vacuum-dry it in a vacuum oven for 24 hours to obtain activated silica gel; (2) chemically bonded alkyl halides on the surface of silica gel: add 5 g of activated silica gel to a 100 mL four-necked flask , then add 40mL toluene and 1mL water as solvent and stir, then add 10mL γ-chloropropyltrimethoxysilane, react at 70°C for 6h, after the reaction, extract the product with toluene in a Soxhlet extractor for 24h, remove The unreacted silane coupling agent in the system is finally vacuum-dried in a vacuum oven for 24h to obtain chloropropylated silica gel (CP-SiO 2 ); (3) chemical grafting of polyethyleneimine PE...

Embodiment 2

[0034] A method for preparing a phenolic molecularly imprinted polymer on the surface of silica gel, comprising the following steps: (1) Activation of silica gel: adding 10 g of silica gel to 60 mL of 20% hydrochloric acid aqueous solution, stirring and activating at 90° C., after 8 hours of activation , filtered, and the filter cake was fully washed with distilled water, and finally vacuum-dried in a vacuum oven for 30 hours to obtain activated silica gel; (2) chemically bonded alkyl halides on the surface of silica gel: add 10 g of activated silica gel to a 100 mL four-necked flask , then add 60mL of xylene and 5mL of water as solvent and stir, then add 15mL of γ-bromopropyltrimethoxysilane, react at 80°C for 8h, after the reaction, extract the product with toluene in a Soxhlet extractor for 30h, Remove the unreacted silane coupling agent in the system, and finally vacuum-dry it in a vacuum oven for 30 hours to obtain bromopropylated silica gel; (3) chemically graft polyethyl...

Embodiment 3

[0036] A method for preparing a phenolic molecularly imprinted polymer on the surface of silica gel, comprising the following steps: (1) Activation of silica gel: adding 5 g of silica gel to 50 mL of 15% hydrochloric acid aqueous solution, stirring and activating at 90° C., after 8 hours of activation , filtered, and the filter cake was fully washed with distilled water, and finally vacuum-dried in a vacuum oven for 30 hours to obtain activated silica gel; (2) chemically bonded alkyl halides on the surface of silica gel: add 5 g of activated silica gel to a 100 mL four-necked flask , then add 50mL of organic solvent and 1mL of water as solvent and stir, then add 10mL of γ-iodopropyltrimethoxysilane, react at 85°C for 7h, after the reaction, extract the product with toluene in a Soxhlet extractor for 30h, Remove the unreacted silane coupling agent in the system, and finally vacuum-dry it in a vacuum oven for 24h to obtain iodopropylated silica gel; (3) chemically graft polyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com