Aminoacid polypeptide nutrient fluid, preparation method thereof and use

A technology of amino acid and nutrient solution, which is applied in the field of fermentation engineering, can solve problems such as differences, and achieve the effects of reasonable composition of enzyme system, promotion of proliferation and fermentation, and balanced composition of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

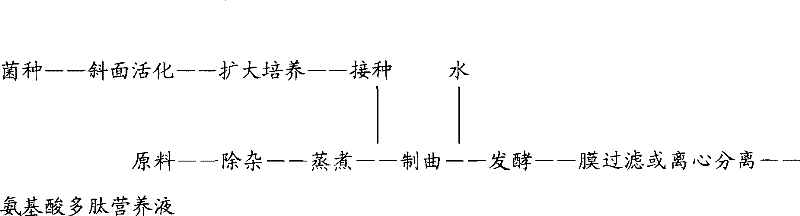

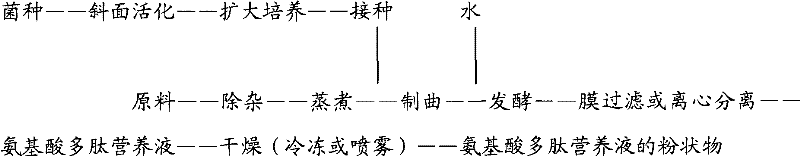

Method used

Image

Examples

preparation Embodiment 1

[0035] (1) Using soybeans and wheat flour as raw materials, the weight ratio of the two is 7:3, remove impurities from the soybeans, soak them, drain them, carry out pressure cooking (pressure 0.08Mpa, time is 25 minutes), cool, and mix in the required Wheat flour, the raw material for koji making.

[0036] (2) Aspergillus oryzae (product number: Huyao 3.042) was gradually expanded and cultivated on inclined planes, triangular flasks and curved discs to obtain seed koji.

[0037] (3) Inoculate the seed koji that accounts for 0.3% of the weight ratio of the koji-making raw materials, and then send it to the disc koji-making device for koji-making, and control the koji material by adjusting the temperature and humidity of the koji-making space, the temperature, humidity and air volume of the ventilation The temperature is 30 ~ 35 ℃, 36 hours out of song.

[0038] (4) Mix the koji and water in a weight ratio of 1:1.0 to obtain a fermented mash at 48°C, place it in a fermentation...

preparation Embodiment 2

[0042] (1) Using soybeans and rice flour as raw materials, the weight ratio of the two is 6:4, remove impurities, soak, drain the soybeans, carry out pressure cooking (pressure 0.08Mpa, time is 25 minutes), cool, and mix in the required Rice flour, the raw material for koji making.

[0043] (2) Mucor radiata Yazhi (product number: CICC3118) was gradually expanded and cultivated on inclined planes, triangular flasks and curved discs to obtain seed koji.

[0044] (3) Inoculate the koji that accounts for 0.6% of the weight ratio of the raw materials for making koji, dilute with sterile water, filter, inoculate with liquid spray, and then carry out grid tray culture, and control the quality of the grid tray by adjusting the temperature and humidity of the cultivation space. The temperature is 25-30°C, and it matures in 54 hours.

[0045] (4) Mix the koji and water in a weight ratio of 1:2.0 to obtain fermented mash at 52°C, place it in a fermenter with a heat preservation jacket,...

preparation Embodiment 3

[0048] (1) Use peanut meal and roasted wheat as raw materials, and the weight ratio of the two is 7:3. The peanut meal is moistened with water, pressure-cooked (0.1MPa, 25 minutes), cooled, and mixed with the required crushed roasted Wheat (20 orders), obtain koji raw material.

[0049] (2) Aspergillus niger (product number: AS3.350) was gradually expanded and cultivated on inclined planes, triangular flasks and curved discs to obtain seed koji.

[0050] (3) Inoculate the kind of koji that accounts for 0.4% of the raw material weight ratio for koji making, and then send it to the koji pool for koji making, and control the temperature of the koji material by adjusting the temperature and humidity of the koji making space, the temperature, humidity and air volume of the ventilation. 30 ~ 33 ℃, 40 hours out of song.

[0051] (4) Mix the koji and water in a weight ratio of 1:2.2 to obtain fermented mash at 43°C, put it in a fermenter with a heat preservation jacket, and keep it for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com