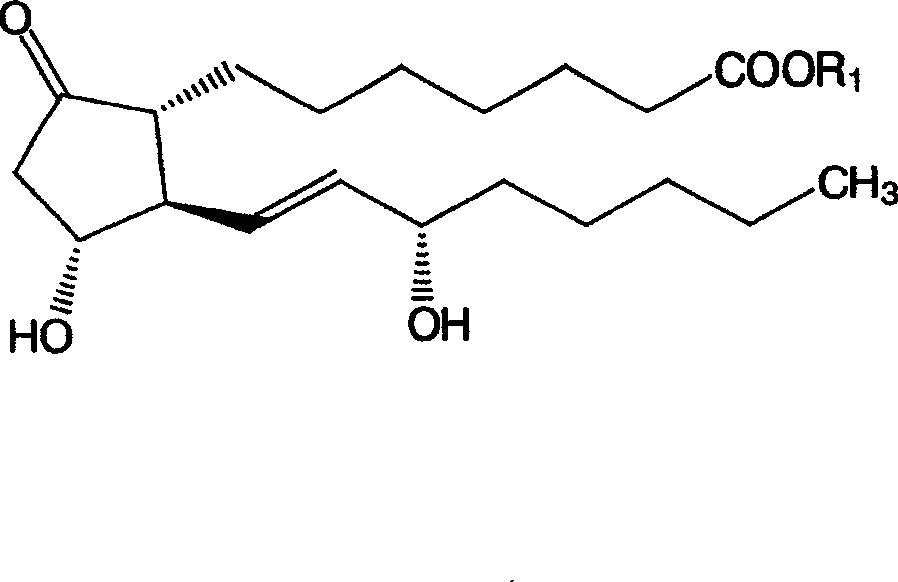

Prostaglandin microemulsion gel rubber preparation and method of producing the same

A prostaglandin and microemulsion gel technology, applied in the field of medicine, can solve the problems of inconvenient use of transdermal drug carriers and low viscosity of microemulsion systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

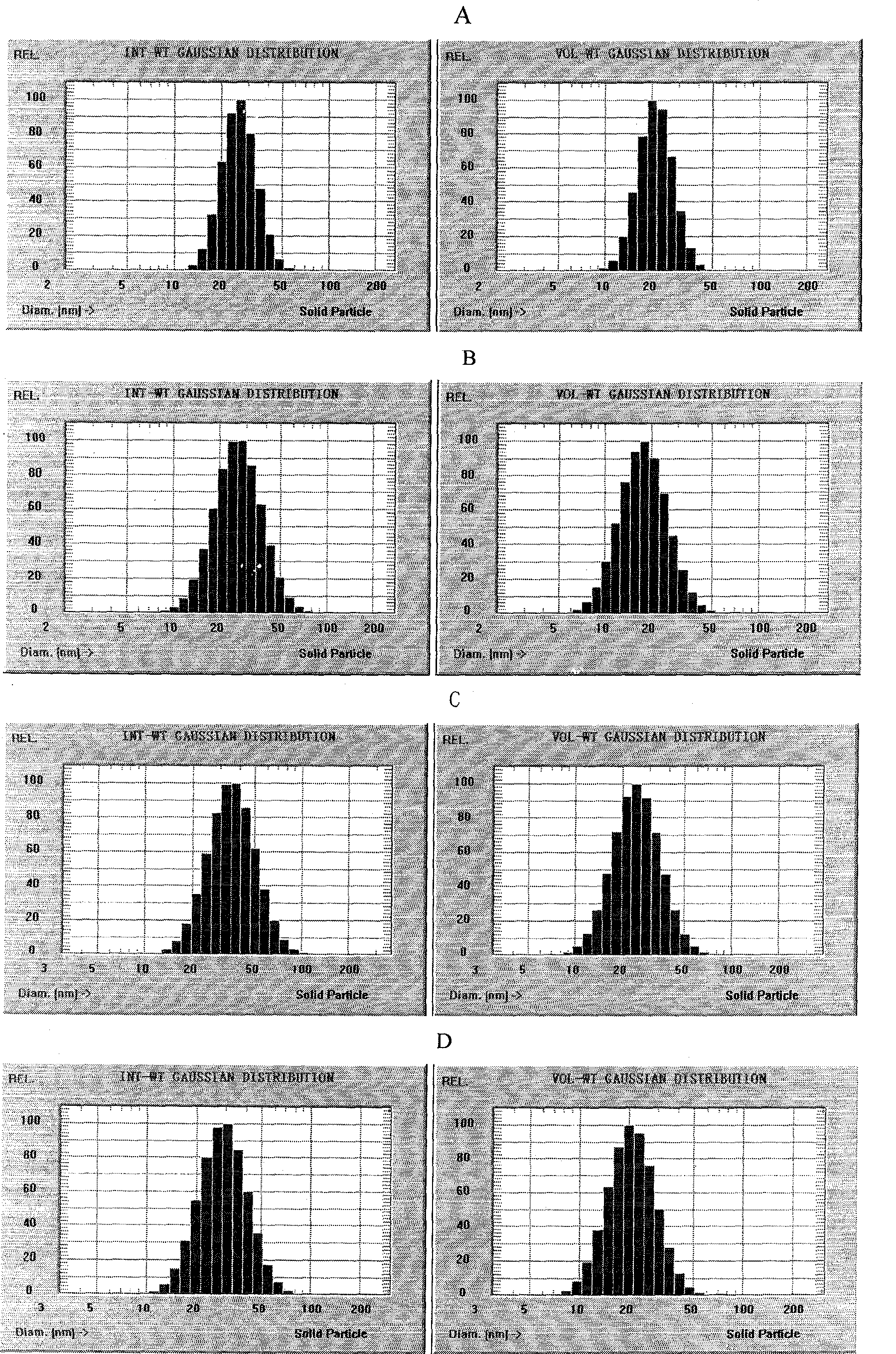

Image

Examples

Embodiment 1

[0035] Prostaglandin E1 0.2g

[0036] Refined soybean oil 10g

[0037] Lecithin 3g

[0038] Poloxamer 188 7g

[0039] Glycerin 10g

[0040] Vitamin C 0.2g

[0041] Methylcellulose 1g

[0042] Water for injection 68.6g

[0043]Preparation method: mix refined soybean oil and lecithin evenly to obtain an oil phase, add prostaglandin E1 into the oil phase to dissolve; disperse methylcellulose in water, swell overnight, then add poloxamer 188, glycerin and vitamin C , mixed uniformly to obtain a water phase; adding the oil phase to the water phase, stirred evenly, and filtered through a 0.22 μm microporous membrane to obtain a prostaglandin E1 microemulsion gel preparation.

Embodiment 2

[0045] Prostaglandin E1 0.5g

[0046] Ethyl oleate 8g

[0047] Polyoxyethylene castor oil 10g

[0048] Isopropanol 6g

[0049] Carbomer 0.5g

[0050] Triethanolamine 0.55g

[0051] Propylparaben 0.05g

[0052] Water for injection 74.4g

[0053] Preparation method: Mix ethyl oleate and polyoxyethylene castor oil evenly to obtain an oil phase, add prostaglandin E1 into the oil phase to dissolve; disperse carbomer in water, swell overnight, then add isopropanol, and mix evenly to obtain water phase; adding the oil phase to the water phase, stirring evenly to obtain a microemulsion; adding triethanolamine to the microemulsion, and mixing evenly to obtain the prostaglandin E1 microemulsion gel preparation.

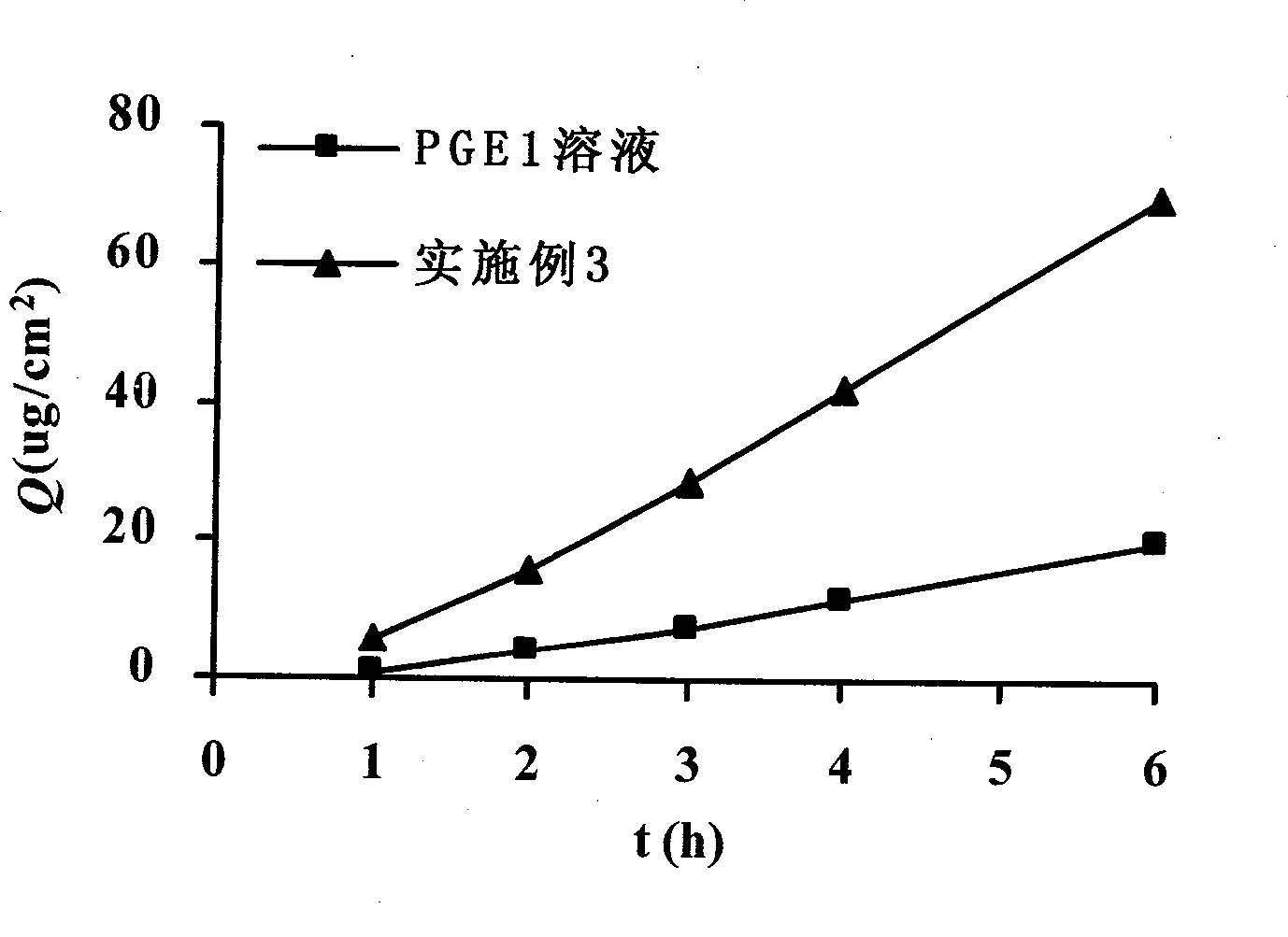

Embodiment 3

[0055] Prostaglandin E1 0.8g

[0056] Isopropyl Palmitate 15g

[0057] Tween 80 12g

[0058] 1,2-propanediol 10g

[0059] Azone 5g

[0060] Disodium EDTA 0.05g

[0061] Hydroxypropyl Cellulose 3g

[0062] Water for injection 54.15g

[0063] Preparation method: mix isopropyl palmitate and azone evenly to obtain an oil phase, add prostaglandin E1 into the oil phase to dissolve; disperse hydroxypropyl cellulose in water, swell overnight, then add Tween 80, 1, 2 -Propylene glycol and disodium edetate are mixed evenly to obtain the water phase; the oil phase is added to the water phase, stirred evenly, and sterilized and filtered through a 0.22 μm microporous membrane to obtain the prostaglandin E1 microemulsion gel preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com