Process for producing crystallization type II branched-chain poly-ammonium phosphate

A branched-chain ammonium polyphosphate and crystallization technology, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as high investment, high pollution, and high energy consumption, and achieve good reliability, simple raw materials, and thermal stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

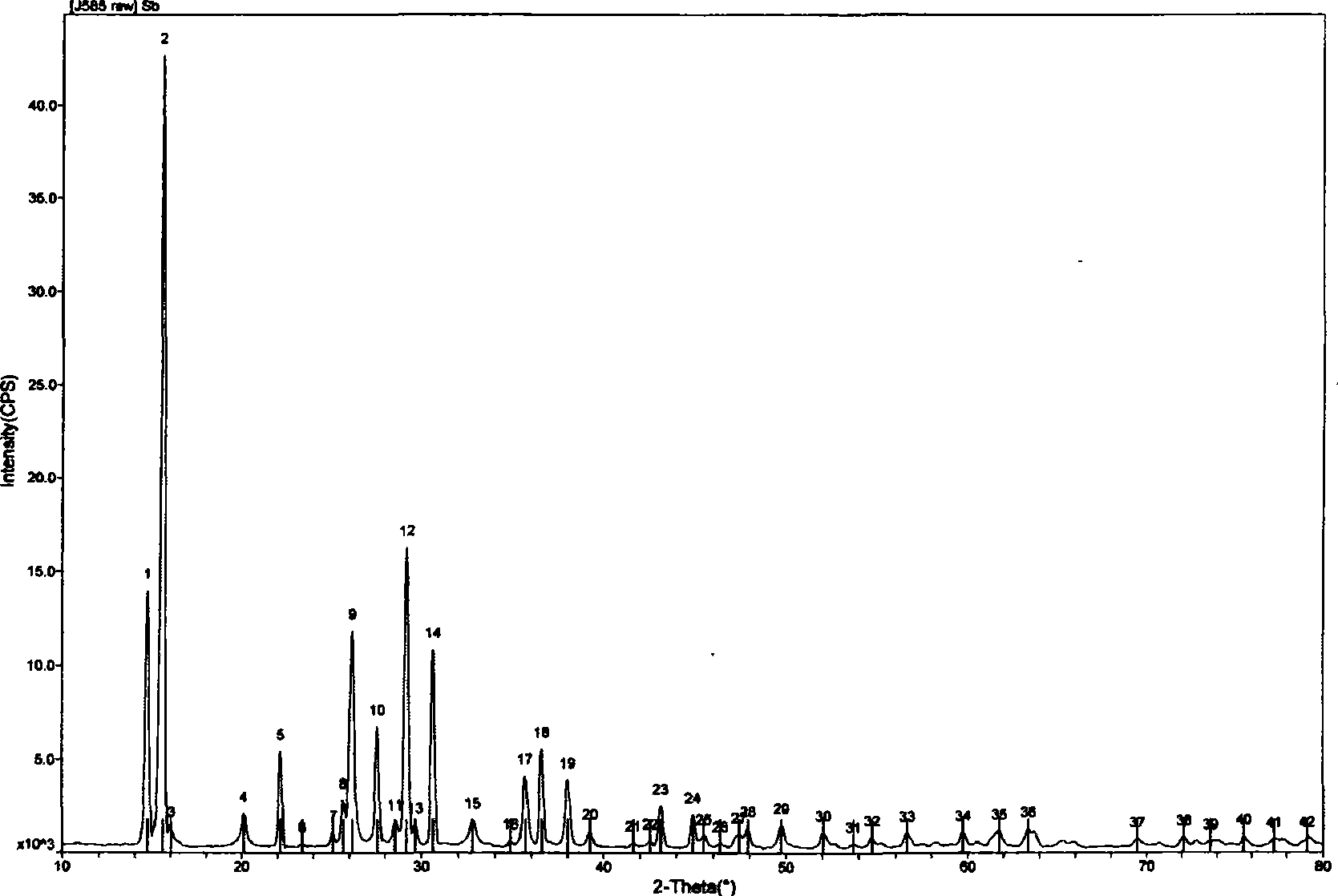

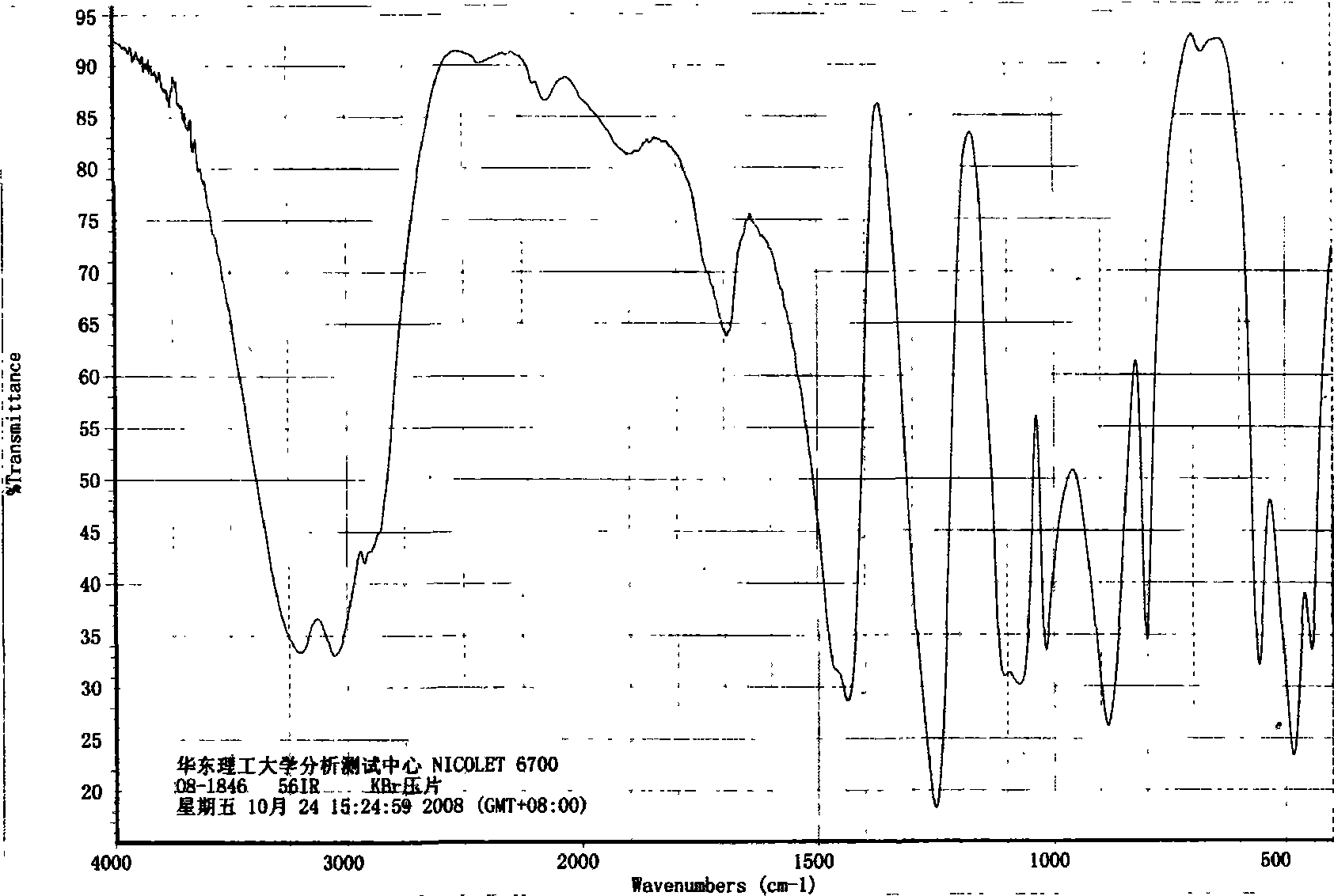

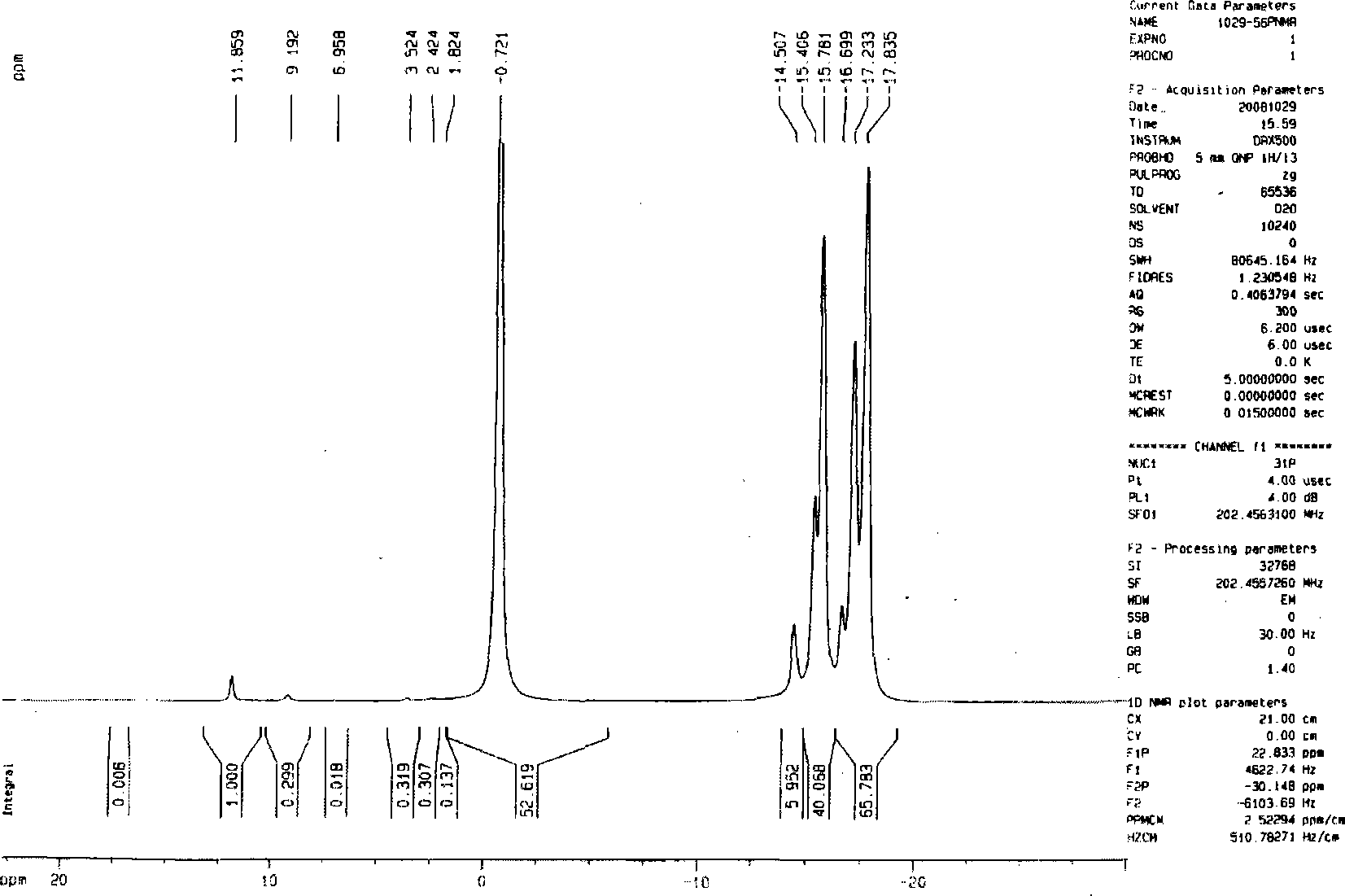

Image

Examples

Embodiment 1

[0032] Add 200L of refined phosphoric acid (85%) into the reactor and raise the temperature to 250°C. During this period, it is best to operate under negative pressure and keep stirring, so as to remove a large amount of water from steaming, or to continuously replace with air to remove water; reach 250 After ℃, gradually add 17.688kg of urea within half an hour and stir, and continuously remove the released gas. After adding urea, add 46.431kg of melamine at 240°C to 250°C at one time and stir, gradually increasing the temperature. When the temperature rises to 300°C, start timing the heat preservation reaction for half an hour, gradually increase the stirring power, and remove the released gas. After half an hour, feed ammonia into the reaction period with a flow rate of 10m 3 / h, the product is initially solidified after a few minutes. The semi-finished products are all transferred to the broken reactor which has been preheated to 250°C. After the transfer, pass the ammo...

Embodiment 2

[0034] In this embodiment, the heat preservation reaction is at 310° C. for half an hour; after turning into crushing reaction gas, ammoniation is passed through ammonia at 310° C. for one hour, and the rest of the operations are the same as in Example 1. 99% of the obtained product is type II ammonium polyphosphate, the average degree of polymerization is 1286, and the 1% weight loss temperature is greater than 275° C. (the weight loss rate is less than 0.5%).

Embodiment 3

[0036] In the embodiment, the heat preservation reaction is at 320° C. for half an hour; after being transferred to the crushing reactor, the ammonification is carried out at 320° C. for 1 hour, and the rest of the operations are the same as in Example 1. The obtained product is a mixed ammonium polyphosphate of type I and type II, with an average degree of polymerization of 1112 and a 1% weight loss temperature of less than 275°C (weight loss rate of less than 0.5%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com