Watersoluble acrylic acid modified saturated polyester, production method and watersoluble baking aluminum paint

A water-based acrylic and aluminum powder paint technology, used in polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of non-repeatable construction, prone to rust, poor hardness and toughness of the paint film, to ensure environmental protection and Fire safety, health protection, scratch resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with embodiment.

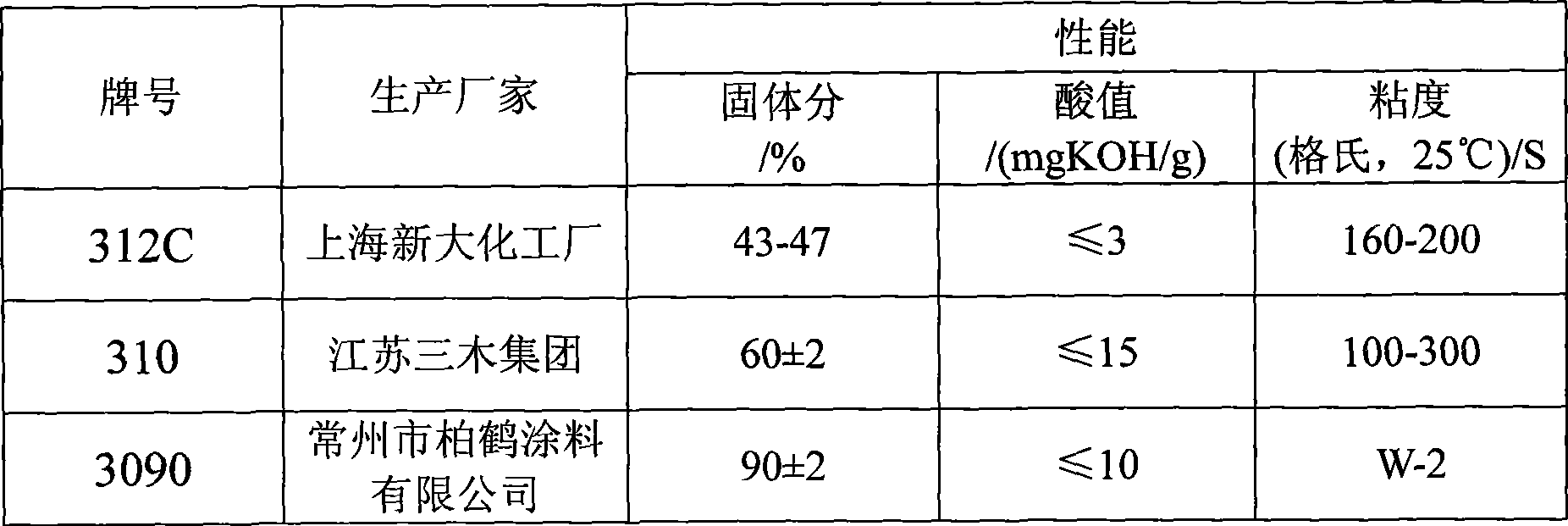

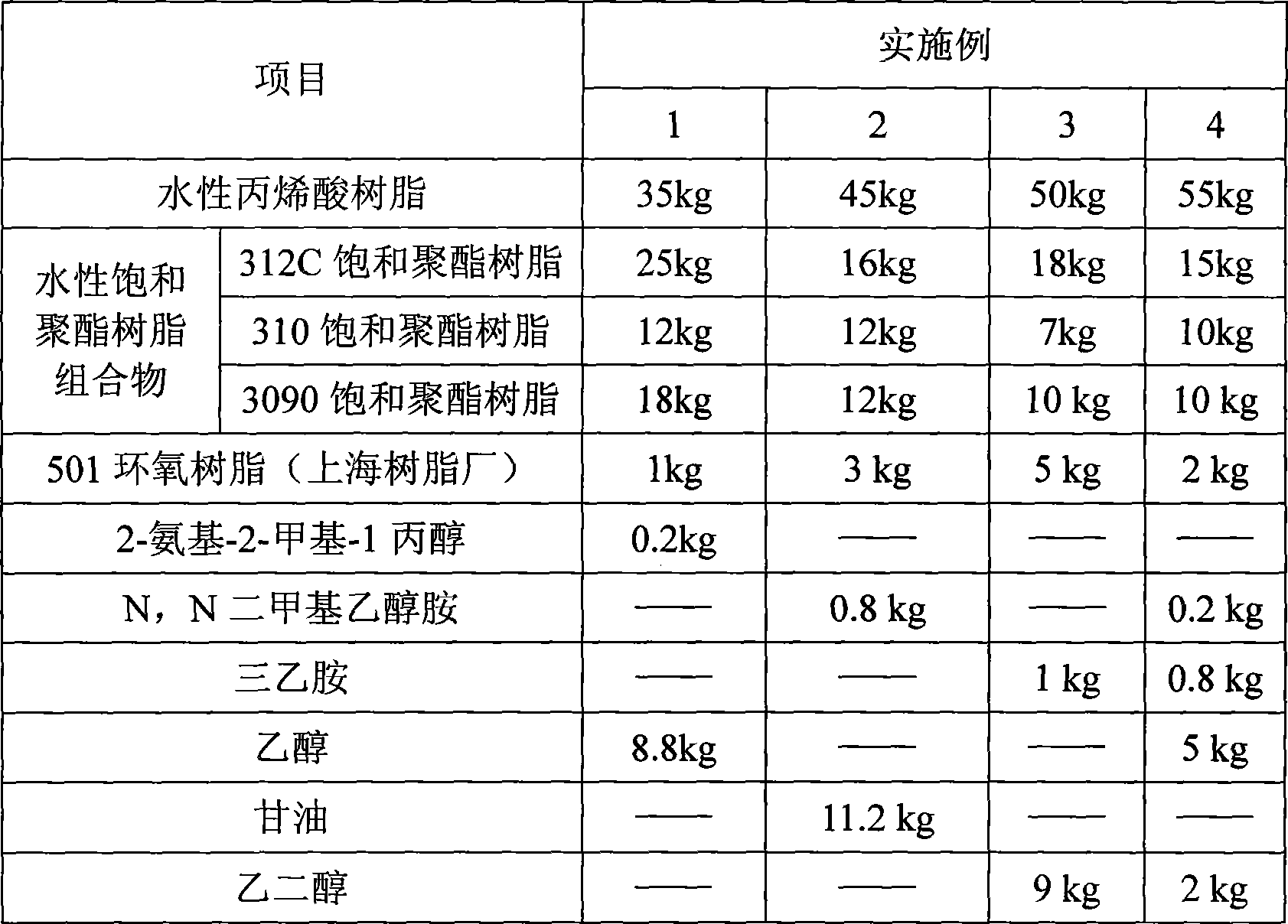

[0046] Table 1 is a recipe example for the synthesis of water-based acrylic modified saturated polyester.

[0047] Table 1:

[0048]

[0049] The preparation method of water-based acrylic acid modified saturated polyester in table 1 is:

[0050] (1) Add the water-based acrylic resin monomer into the disperser, stir at 600n / min for 30min, then add 312C saturated polyester resin, stir for 30min, then add 310 saturated polyester resin, stir for 30min, then add 3090 saturated polyester resin Ester resin, stirred for 30min;

[0051] (2) Increase the speed of the disperser to 1200n / min, add epoxy resin and stir for 30min;

[0052] (3) Increase the speed of the disperser to 2200n / min, add the neutralizer and stir for 30min;

[0053] (4) Finally, add alcohol diluent and stir evenly to obtain the product.

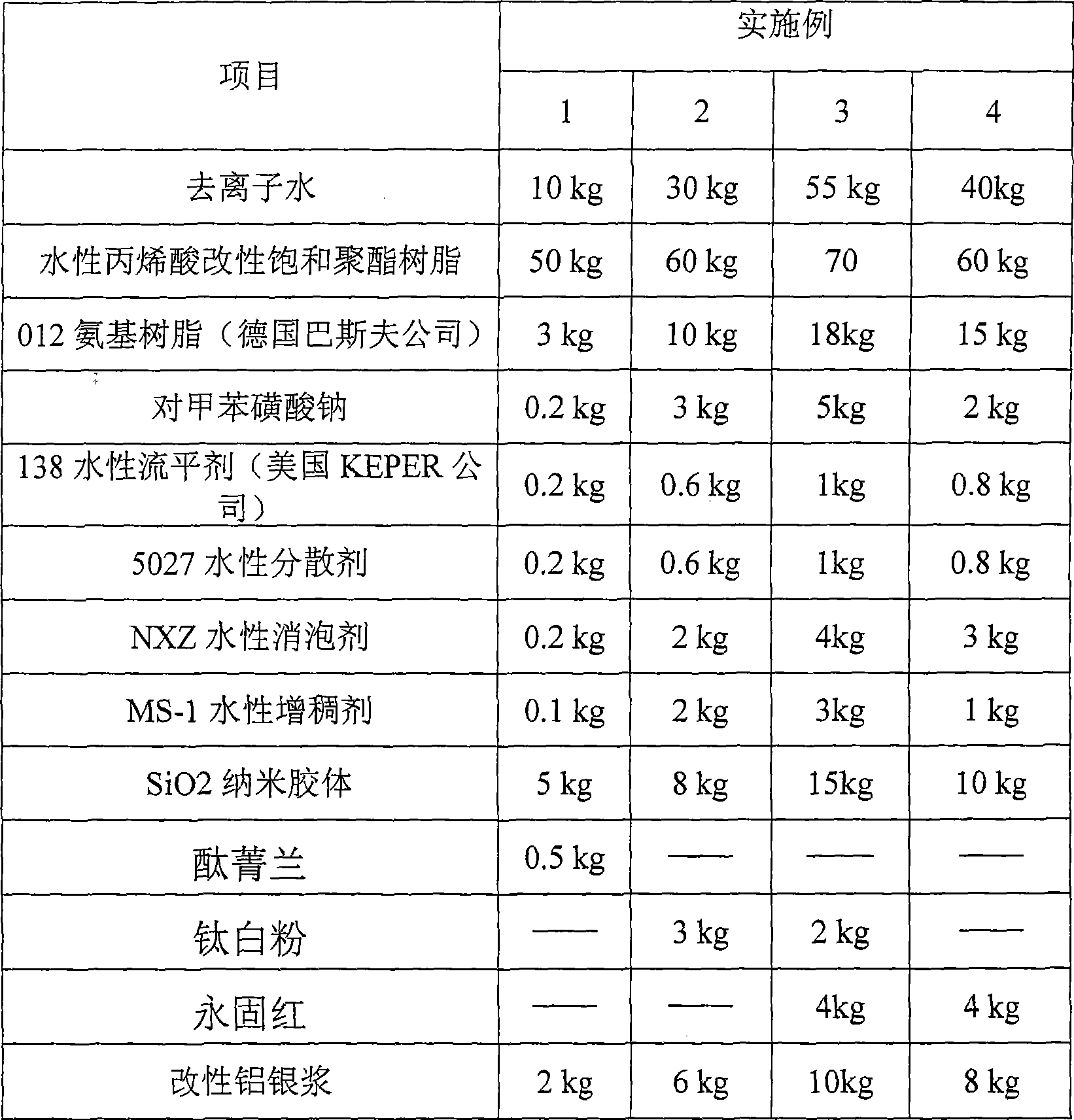

[0054] Table 2 is the embodiment of water-based baking aluminum powder paint.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com