Zirconium oxide coating on aluminum alloy surface and method for producing the same

A technology of aluminum alloy surface and zirconia, applied in the direction of coating, electrolytic coating, electrolytic inorganic material coating, etc., can solve the problems of annealing of base material, low melting point of aluminum alloy, etc., and achieve the effect of high bonding strength and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

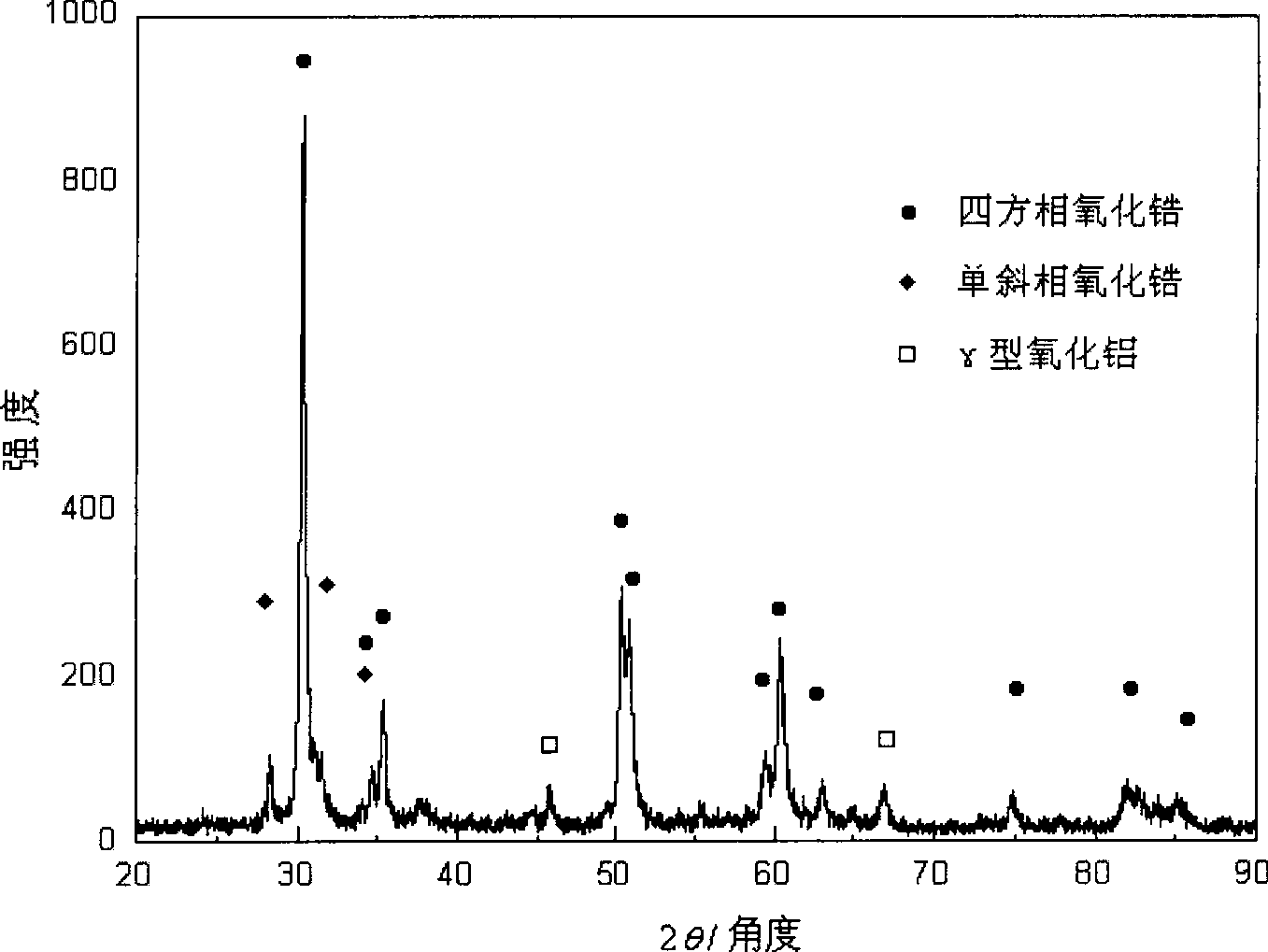

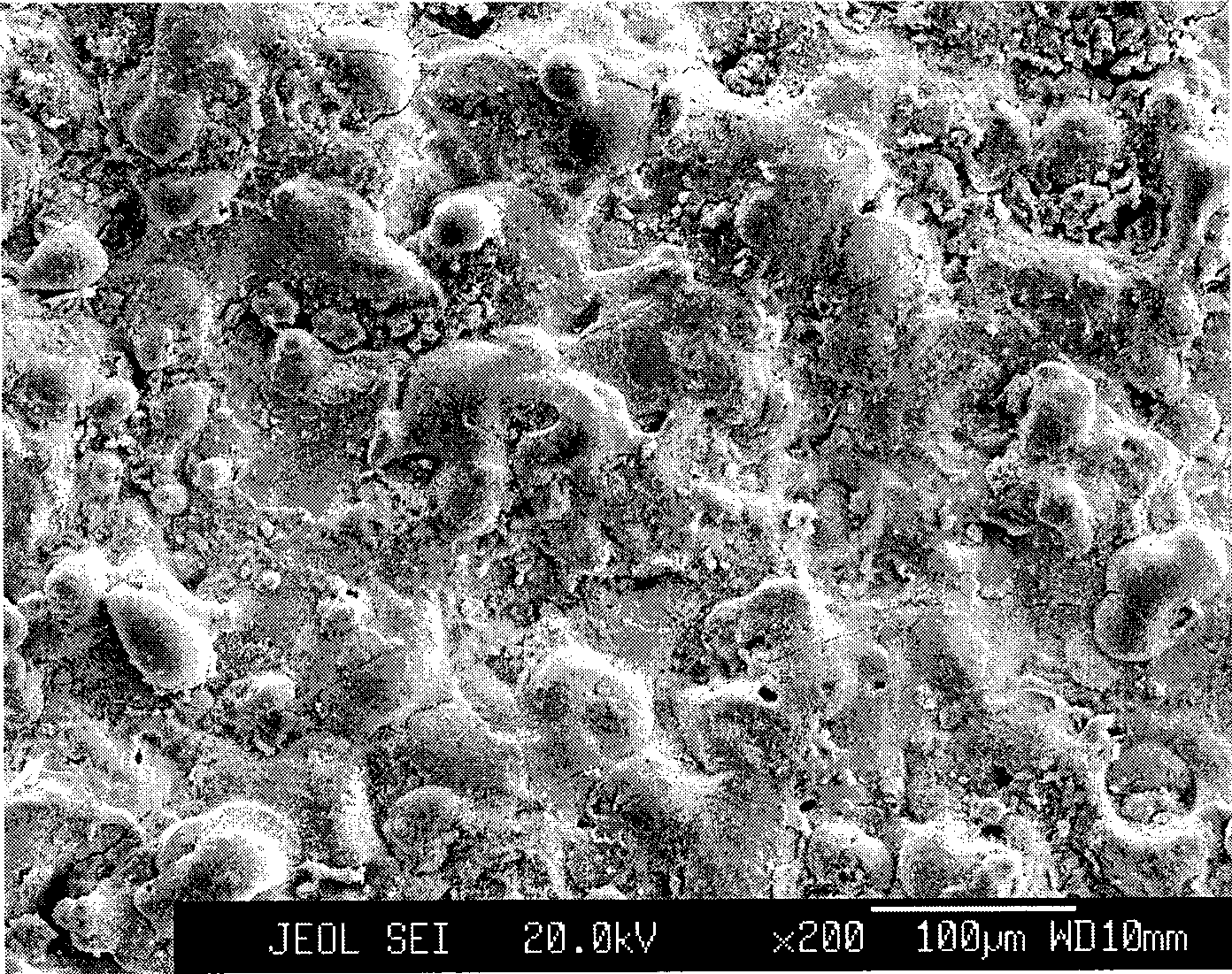

Embodiment 1

[0028] Take an aluminum alloy test piece with a size of 60×60mm and mark it as 1#, use decontamination powder to degrease, and prepare electrolyte according to the following mass and volume ratio, zirconium hydroxide 5g / l, potassium hydroxide 2g / l. The aluminum alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. The frequency of the power supply is 50Hz, the positive phase and negative phase current duty ratios are 0.4, the positive phase voltage value is 500V, the negative phase voltage value is 100V, the processing time is 60min, and the thickness of the resulting coating is 60 microns. The hardness is 1700HV.

Embodiment 2

[0030] Take an aluminum alloy test piece with a size of 60×60mm, mark it as 2#, go through alkali washing, pickling and other processes in turn, prepare electrolyte according to the following mass and volume ratio, zirconia 5g / l, sodium hydroxide 2g / l . The aluminum alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. The frequency of the power supply is 500Hz, the positive phase and negative phase current duty ratios are 0.4 respectively, the positive phase voltage value is 550V, the negative phase voltage value is 110V, the processing time is 90min, the thickness of the generated coating is 95 microns, and the coating hardness is It is 1800HV.

Embodiment 3

[0032] Take a titanium alloy test piece with a size of 60×60mm and mark it as 3#, go through the processes of alkali washing and pickling in sequence, and prepare the electrolyte according to the following mass and volume ratio, zirconia 10g / l, ammonia water 2g / l. The aluminum alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. The frequency of the power supply is 500Hz, the positive phase and negative phase current duty ratios are 0.2, the positive phase voltage value is 580V, the negative phase voltage value is 130V, the processing time is 120min, the thickness of the generated coating is 140 microns, and the coating hardness is It is 1800HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com