Phosphorous beta molecular sieve and preparation thereof

A technology of β molecular sieve and molecular sieve, which is applied in the field of β molecular sieve and its preparation, can solve the problems such as activity reduction, and achieve the effect of improving activity and activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The β molecular sieve (produced by Hunan Jianchang Petrochemical Company, SiO 2 / AL 2 o 3 =25, exchanged with ammonium nitrate solution, Na 2 (0≤0.2%Wt) raw powder is deaminated under the flowing air in the muffle furnace through programmed temperature rise and roasting. The temperature rise program is 100°C constant temperature for 0.5 hours, and the temperature is raised to 300°C after 1 hour, and the temperature is constant temperature for 2 hours, and then after 1 The temperature was raised to 400°C in 1 hour, kept at this temperature for 2 hours, then raised to 570°C in 1 hour, and fired at this temperature for 4 hours.

[0037] Weigh 15g of ammonium dihydrogen phosphate, dissolve it in 150g of distilled water, add 30g of β molecular sieve roasted under the above conditions into the aqueous solution, stir evenly and add it into a stainless steel autoclave, which is fixed on a rotatable bracket in the oven Above, the temperature was raised from room temperature t...

Embodiment 2

[0050] Take by weighing 7.5g ammonium dihydrogen phosphate, dissolve in 150g distilled water, add 30g through the beta molecular sieve roasted in embodiment 1 in this aqueous solution, add in the stainless steel autoclave after stirring evenly, the autoclave is fixed in the baking oven. On a rotating support, heat up from room temperature to 180°C after 2 hours, and dynamically treat at this temperature for 4 hours. After cooling, take the slurry out of the autoclave, wash, filter and dry at 110°C, and the obtained molecular sieve sample is recorded as Pβ -2.

[0051] After X-ray fluorescence analysis, its P 2 o 5 The content is 1.81%.

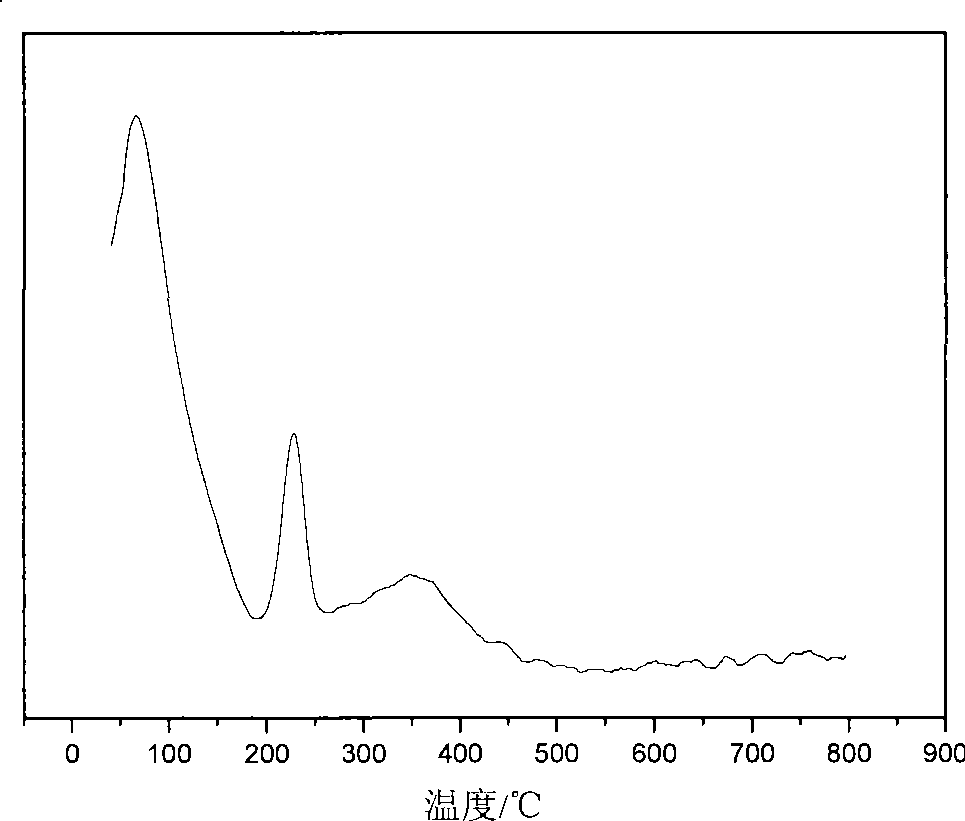

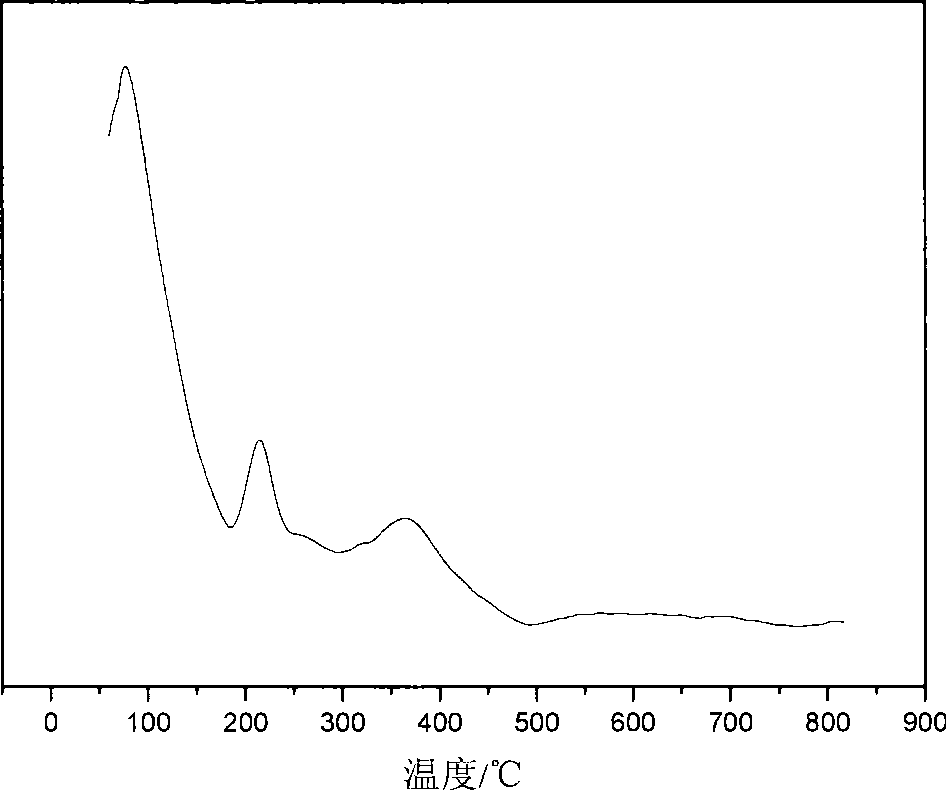

[0052] Pβ-2 thermogravimetric analysis see attached image 3 , NMR analysis see attached Figure 9 .

Embodiment 3

[0054] Weigh 22.5g of ammonium dihydrogen phosphate, dissolve it in 150g of distilled water, add 30g of the Hβ molecular sieve roasted in Example 1 to the aqueous solution, stir it evenly and add it into a stainless steel autoclave, which is fixed in a rotatable oven. After 2 hours from room temperature to 200°C, the temperature was dynamically treated at this temperature for 4 hours. After cooling, the slurry was taken out from the autoclave. After washing, filtering and drying at 110°C, the obtained molecular sieve sample was recorded as Pβ- 3.

[0055] After X-ray fluorescence analysis, its P 2 o 5 The content is 3.72%.

[0056] Pβ-3 thermogravimetric analysis see attached Figure 4 , NMR analysis see attached Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com