Automation production process for degumming mulberry bark

A production process and degumming technology, which is applied in the chemical post-treatment of fibers, chemical production of bast fibers, textiles and papermaking, etc., can solve the disadvantages of improving production efficiency and process quality control reliability, and can not effectively reduce the operator Problems such as labor-intensive production environment and inability to connect automatically can achieve the effect of improving the production environment, reducing energy consumption, and controlling effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

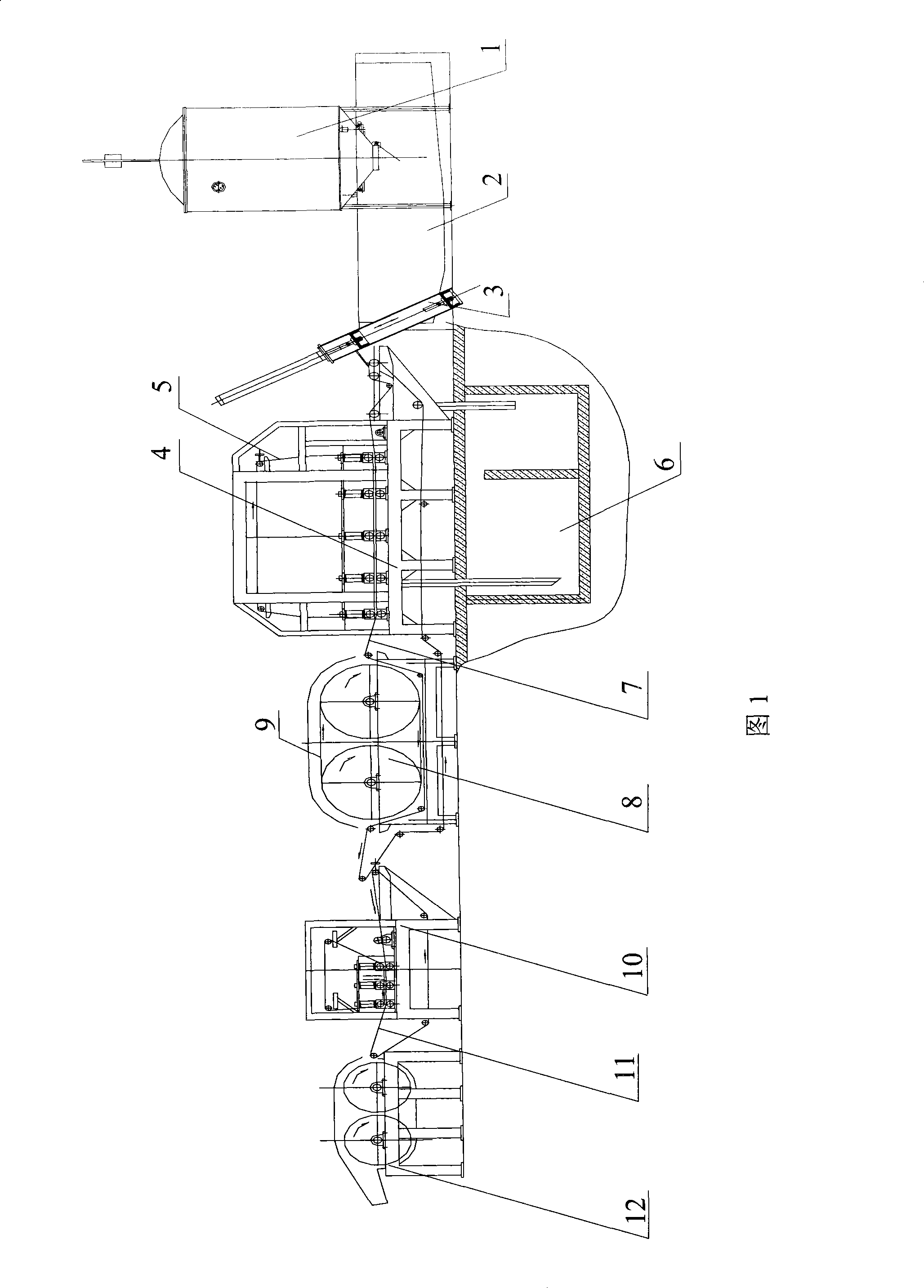

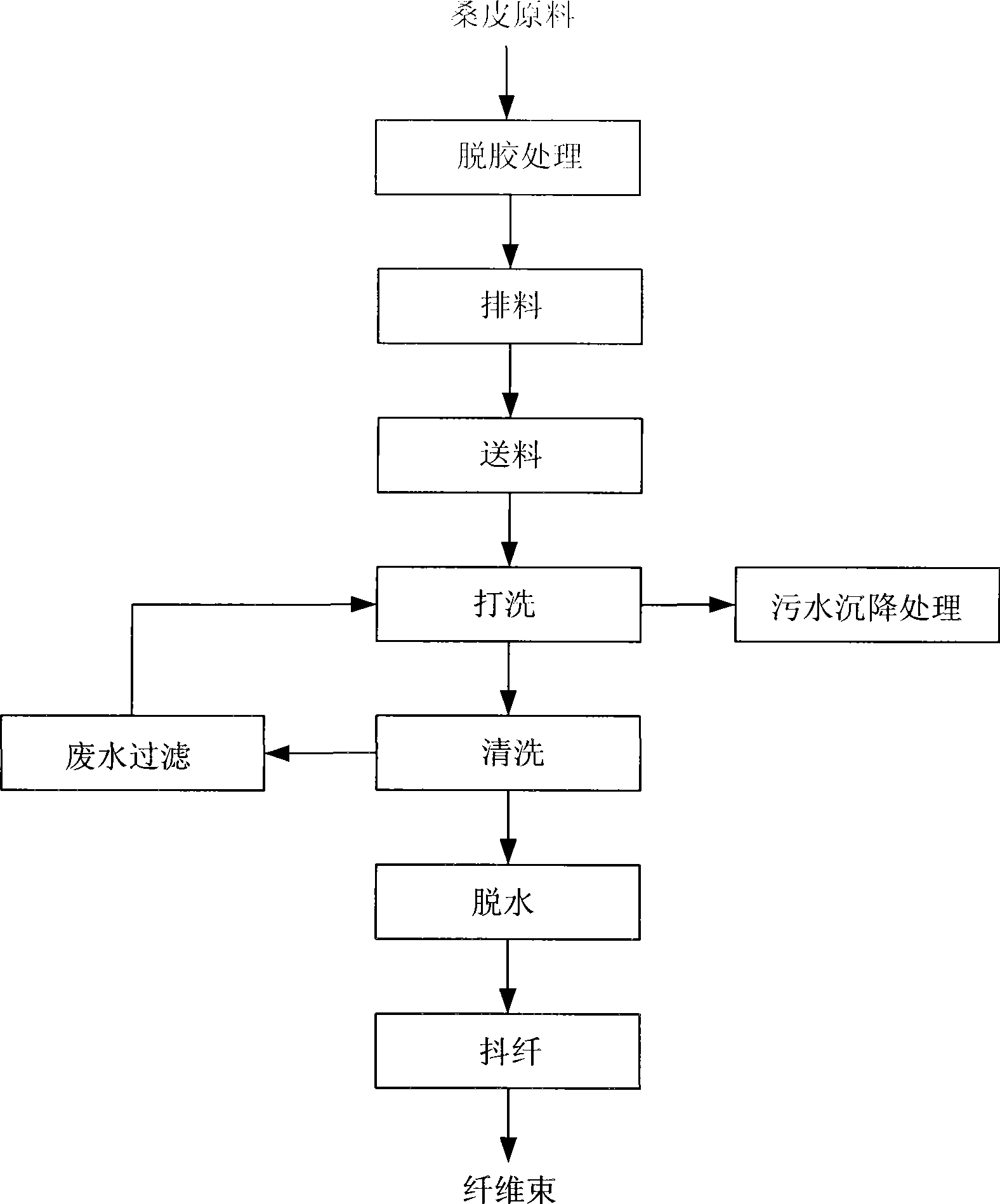

[0030] As shown in Figures 1 and 2, the mulberry bark degumming automatic production line equipment used in the present invention consists of reactor 1, cylinder piston feeding mechanism 3, cleaning mechanism 4, main transmission curtain 7, cleaning mechanism 8, dehydration mechanism 10 and The shaking and scattering mechanisms 12 are sequentially connected to form. Wherein, the cleaning mechanism 4 and the cleaning mechanism 8 are connected through the main transmission curtain 7, so that the main transmission curtain 7 becomes the main transmission device of the whole mulberry peel degumming automatic production line equipment. Described reaction kettle 1 is used for carrying out biological degumming or chemical cooking of mulberry raw material according to known technology, is about to place the prepared special biological degumming liquid in the mulberry raw material after soaking, in appropriate liquor ratio and Soak for a certain period of time under temperature conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com