Membrane aeration biomembrane process and apparatus for sewerage short-cut denitrification

A technology of membrane aerated biofilm and biofilm reactor, which is applied in the direction of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of starting and controlling the nitrosation process. Clear, difficult to achieve nitrosation performance, high infrastructure investment and other issues, to achieve the effects of avoiding substrate competition, high short-range denitrification efficiency, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

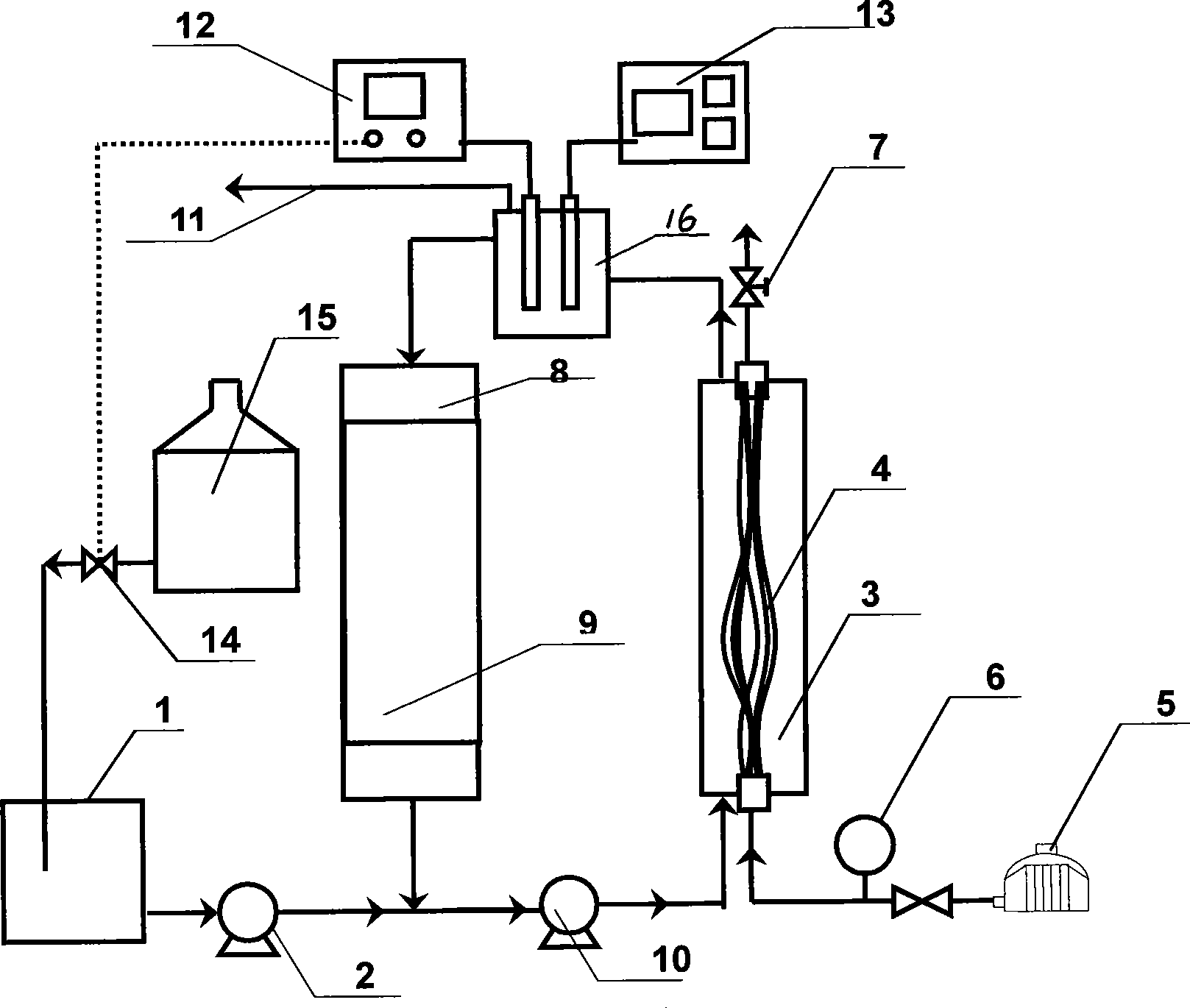

[0023] Example 1: Short-range denitrification treatment of high ammonia nitrogen wastewater by membrane aeration biofilm process.

[0024] The control device is mainly composed of an inlet pump 1, a membrane aeration biofilm area 3, a denitrification biofilm area 8, a mixed liquid circulation pump 10 and its connecting pipelines. 2 is added to the membrane aeration biofilm reactor 3, in which the bubble-free aeration membrane 4 is installed, and microbial biofilm will grow on its surface to play the role of nitrosation. Air is passed through the air compressor (or air pump) 5 in the bubble-free aeration membrane, and the pressure of the air is displayed by a pressure gauge 6 and regulated by an air pressure regulating valve 7 . After the sewage flows through the membrane aeration biofilm reactor 3, it enters the denitrification biofilm area 8, and the denitrification area 8 is filled with a biofilm carrier 9, and a denitrification biofilm grows on the surface of the biofilm ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com