Etherification reaction method of isomeric olefine

A technology for isomerization of olefins and etherification, applied in chemical instruments and methods, ether preparation, organic chemistry, etc., can solve problems such as magnetic disappearance, achieve the effects of improving mass transfer, reducing energy consumption, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

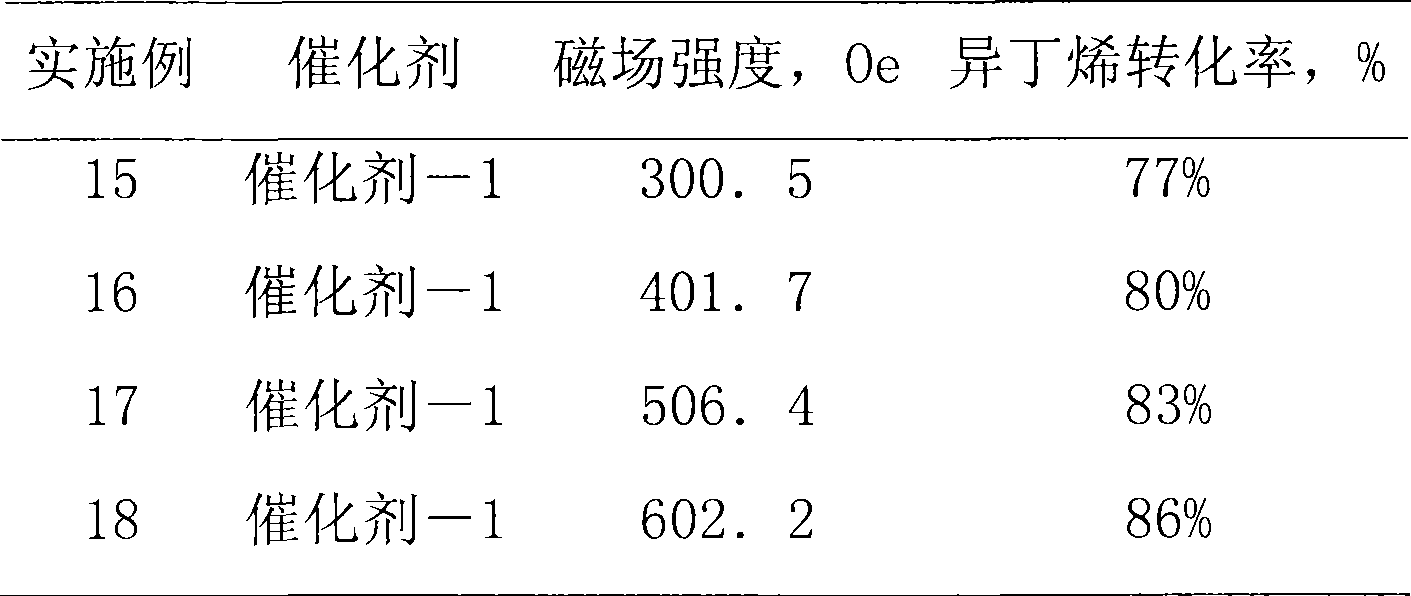

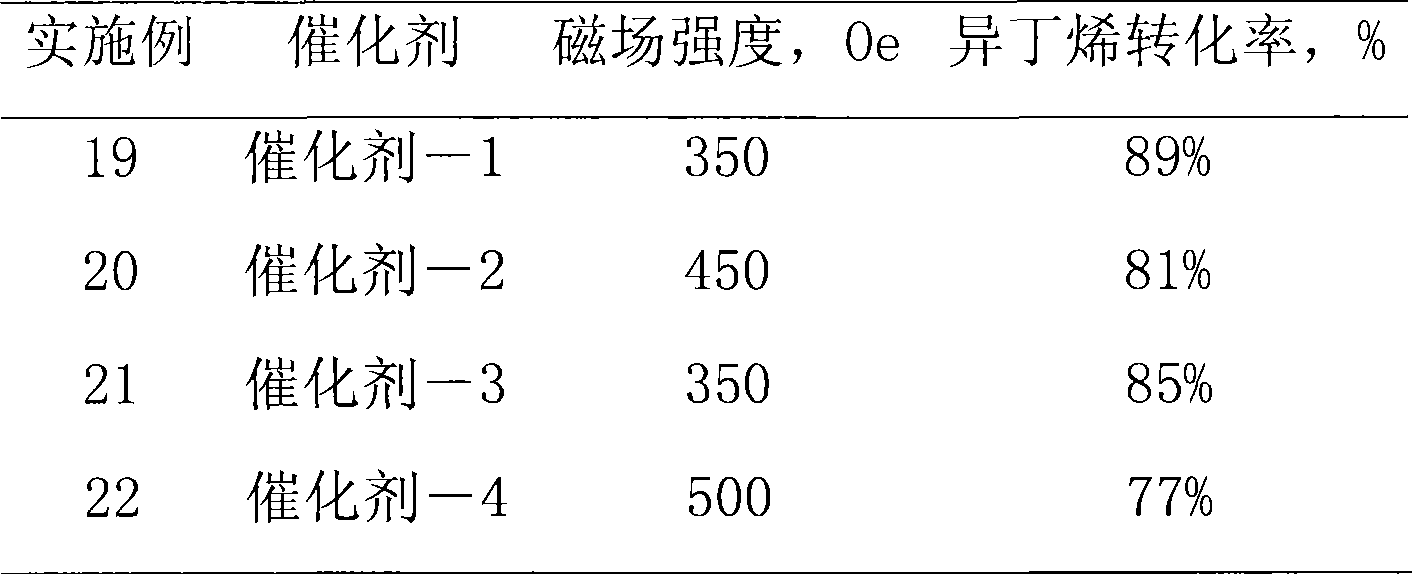

Examples

Embodiment 1

[0053] Mix and dissolve 26.5ml of styrene and 0.24g of benzoyl peroxide, put it in a 75°C water bath, stir for 15-25min, and pour the solution into a three-necked flask when the solution has a certain viscosity. Add 8g of iron powder and 0.1g of tetrabutoxytitanium into the three-necked flask, and stir mechanically until completely uniform. Add 80ml of 1wt% gelatin aqueous solution, raise the temperature to 80°C with stirring, and keep for 2h; raise the temperature to 85°C, keep for 2h; then raise the temperature to 90°C, keep for 6h, and the reaction is terminated. The reaction system was cooled and discharged, washed repeatedly with distilled water, and dried naturally to obtain magnetic cores.

Embodiment 2

[0055] Mix and dissolve 17.5ml of styrene, 9.7ml of divinylbenzene, and 0.21g of benzoyl peroxide, put in a water bath at 80°C, stir for 15-25min, and pour the solution into a three-necked flask when the solution has a certain viscosity. Add 8g of iron powder and 0.1g of tetrabutoxytitanium into the three-necked flask, and stir mechanically until completely uniform. Add 80ml of 2.5wt% polyvinyl alcohol aqueous solution, raise the temperature to 82°C with stirring, keep for 2h; raise the temperature to 86°C, keep for 2h; then raise the temperature to 90°C, keep for 6h, the reaction is terminated. After the reaction system is cooled, the material is discharged, washed repeatedly with distilled water, and dried naturally to obtain the magnetic core.

Embodiment 3

[0057] Mix and dissolve 17.5ml of styrene, 9.7ml of divinylbenzene, and 0.25g of azobisisobutyronitrile, put in a 74°C water bath, stir for 15-25min, and pour the solution into a three-necked flask when the solution has a certain viscosity. Add 8g of iron powder and 0.1g of tetrabutoxytitanium into the three-necked flask, and stir mechanically until completely uniform. Add 70ml of 1wt% gelatin aqueous solution, raise the temperature to 80°C with stirring, and keep for 2h; raise the temperature to 86°C, keep for 2h; then raise the temperature to 91°C, keep for 6h, and the reaction is terminated. After the reaction system is cooled, the material is discharged, washed repeatedly with distilled water, and dried naturally to obtain the magnetic core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com