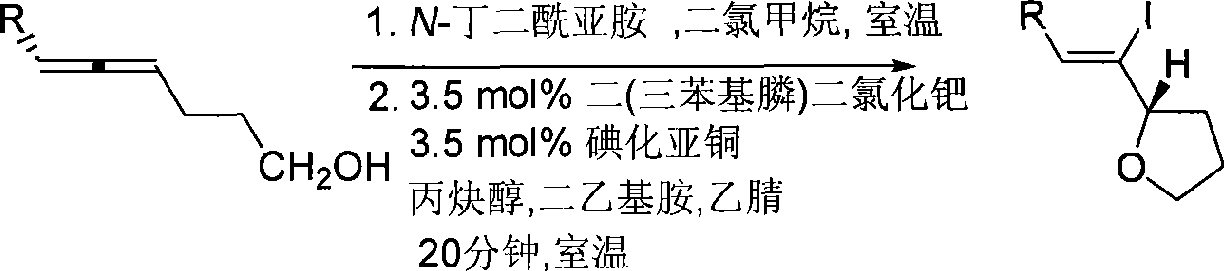

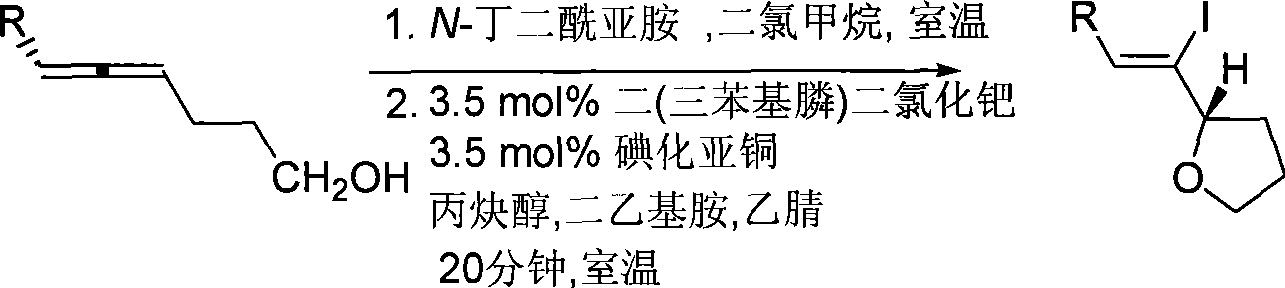

Process for synthesizing optical activity 2-(1'(Z) alkenyl iodo-alkyl) tetrahydrofuran

An alkenyl iodoalkyl, optically active technology, which is applied in the field of efficient synthesis of optically active 2-alkyl-substituted tetrahydrofuran compounds, can solve the problems of unfriendly and expensive environments, and achieve mild conditions and short reaction times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add (R)-4,5-diendecyl alcohol (33.4mg, 0.20mmol, 95% ee), dichloromethane, NIS (54.4mg, 0.24mmol) into the reaction tube, start stirring at room temperature, and react for 55min . Add saturated Na 2 S 2 o 3 solution, stirred until colorless, extracted with ether, dried over anhydrous sodium sulfate, filtered, concentrated, flash column chromatography to obtain (S)-2-(1-iodo-1(Z)-heptenyl)tetrahydrofuran and (R )-2-(1-iodo-1(E)-heptenyl)tetrahydrofuran liquid, 54.3 mg in total, 93% yield, Z / E=90 / 10.

[0023] 1 H NMR (300MHz, CDCl 3 )δ[6.31, (t, J=7.8Hz, E-isomer, 0.1H), 5.90(t, J=6.8Hz, Z-isomer, 0.9H)], 4.18(t, J=6.5Hz, 1H) , 4.08-3.95(m, 1H), 3.92-3.80(m, 1H), 2.21-2.10(m, 2H), 2.10-1.80(m, 4H), 1.46-1.22(m, 6H), 0.88(t, J=6.8Hz, 3H).

[0024] Under the protection of nitrogen, the mixture obtained above [(S)-2-(1-iodo-1(Z)-heptenyl)tetrahydrofuran and (R)-2-(1-iodo-1(E)-heptene base) tetrahydrofuran] (54.3mg, 0.18mmol, Z / E=90 / 10), propynyl alcohol (3.2mg, 0.05...

Embodiment 2

[0031] (R)-4,5-dienyl dodecanol (34.9mg, 0.19mmol, 98%ee), dichloromethane, NIS (54.7mg, 0.24mmol) were reacted at room temperature for 45min to obtain the product (S)-2 -(1-iodo-1(Z)-octenyl)tetrahydrofuran and (R)-2-(1-iodo-1(E)-octenyl)tetrahydrofuran total 51.7 mg, liquid, yield 88%, Z / E=90 / 10.

[0032] 1 H NMR (300MHz, CDCl 3 )δ[6.31(t, J=7.7Hz, E-isomer, 0.1H), 5.91(t, J=6.8Hz, Z-isomer, 0.9H)], 4.19(t, J=6.2Hz, 1H), 4.06-3.95(m, 1H), 3.92-3.80(m, 1H), 2.21-2.10(m, 2H), 2.10-1.80(m, 4H), 1.46-1.22(m, 8H), 0.87(m, 3H ).

[0033]Under the protection of nitrogen, the product [(S)-2-(1-iodo-1(Z)-octenyl)tetrahydrofuran obtained above was mixed with (R)-2-(1-iodo-1(E)-octene base) tetrahydrofuran] (51.7mg, 0.17mmol, Z / E=90 / 10), propynyl alcohol (2.7mg, 0.048mmol), diethylamine (3.2mg, 0.04mmol), bis(triphenylphosphine) Palladium dichloride (4.3mg, 0.006mmol) reacted with cuprous iodide (1.5mg, 0.008mmol) in anhydrous acetonitrile, added diethyl ether to quench the reac...

Embodiment 3

[0040] 1) Add N-iodosuccinimide (0.24mmol) di Chloromethane (1 mL), stirred at room temperature for 45-55 minutes;

[0041] 2) After step (1) was completed, water (10 mL) and saturated sodium thiosulfate (10 mL) were added, extracted with diethyl ether (20 mL×3), and dried over anhydrous sodium sulfate. Concentrate under reduced pressure after filtering off anhydrous sodium sulfate, and obtain the product after silica gel column chromatography;

[0042] 3) Transfer the product obtained in (2) to the reaction flask, then add bis(triphenylphosphine) palladium dichloride (0.007mmol), cuprous iodide (0.007mmol), propynyl alcohol (0.057mmol) ), diethylamine (0.06mmol) and anhydrous acetonitrile (2mL), stirred and reacted at room temperature for 20 minutes;

[0043] 4) After step (3) is completed, direct flash silica gel column chromatography to obtain (S)-2-(1'(Z)alkenyl iodoalkyl)tetrahydrofuran.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com