Green coloring composition for filter and filter

A coloring composition and color filter technology, which is applied in the field of color filters, can solve problems such as poor leveling, poor fluidity, and inability to obtain a coating film with uniform film thickness, and achieve high contrast ratio and brightness. The effect of good stability and reduction of existing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

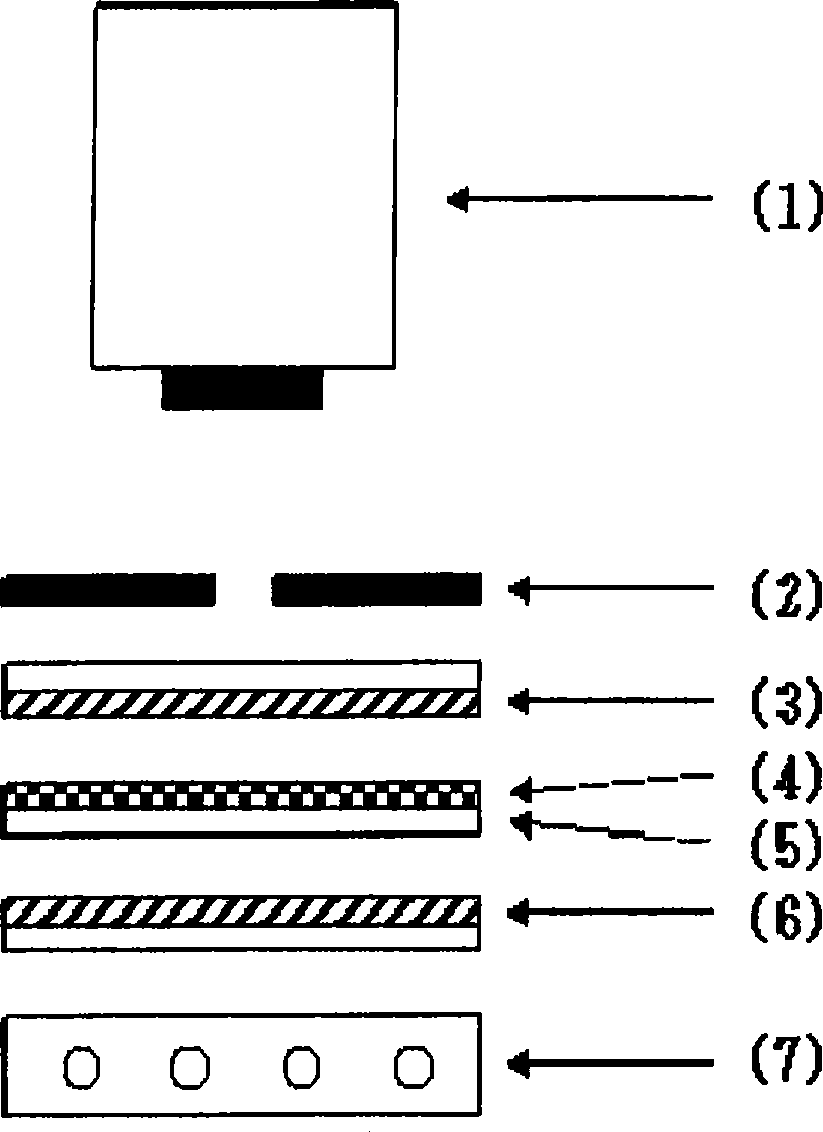

[0263] [Preparation of color filter]

[0264] The color filter of the present invention can be produced by a printing method or a photolithography method.

[0265] The formation of color filter segments using the printing method can be patterned only by repeatedly printing and drying the coloring composition prepared as printing ink. Therefore, as a production method of color filters, mass production at low cost Excellent. Furthermore, with the development of printing technology, it is possible to print fine patterns with high dimensional accuracy and smoothness. For printing, it is preferable to form such a composition that the ink is not dried but cured on the printing plate or the surface layer (blanket). In addition, it is also important to control the fluidity of the ink on the printing press, and it is also possible to adjust the viscosity of the ink by using a dispersant or an extender pigment.

[0266] When the color filter segment is formed by photolithography, it ...

Embodiment

[0277] Hereinafter, although this invention is demonstrated based on an Example, this invention is not limited to these Examples. In addition, in Examples and Comparative Examples, "parts" means "parts by weight". In addition, Mn and Mw represent number average molecular weight and weight average molecular weight, respectively.

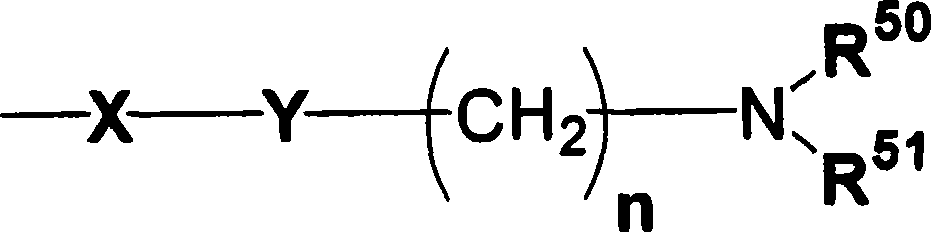

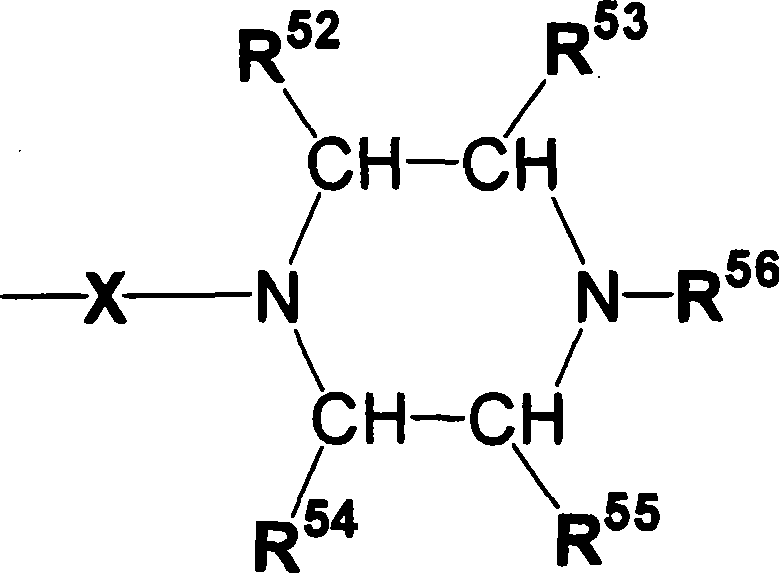

[0278] (1) Average molecular weight of basic resin type dispersant (a)

[0279] In the following examples and comparative examples, the number average molecular weight (Mn) and weight average molecular weight (Mw) of the basic resin type dispersant are HLC-8320GPC (manufactured by Tosoh Co., Ltd.) as the device, using SUPER-AW3000 The polystyrene-equivalent number average molecular weight (Mn) and weight average molecular weight (Mw) were measured using N,N-dimethylformamide of 30 mM triethylamine and 10 mM LiBr as an eluent as a column.

[0280] (2) Amine value

[0281] The amine value of the basic resin type dispersant is a value obtained by conv...

no. 1 Embodiment approach

[0287] The green coloring composition containing the said basic resin type dispersant (a) as an essential component is demonstrated using an Example (Example I series) and a comparative example (Comparative Example I series).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com