Method for preparing spherical catalyst and special device thereof

A special device and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex process, low yield rate of finished products, non-continuous production, etc., and achieve the yield rate of finished products High, uniform particle size, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

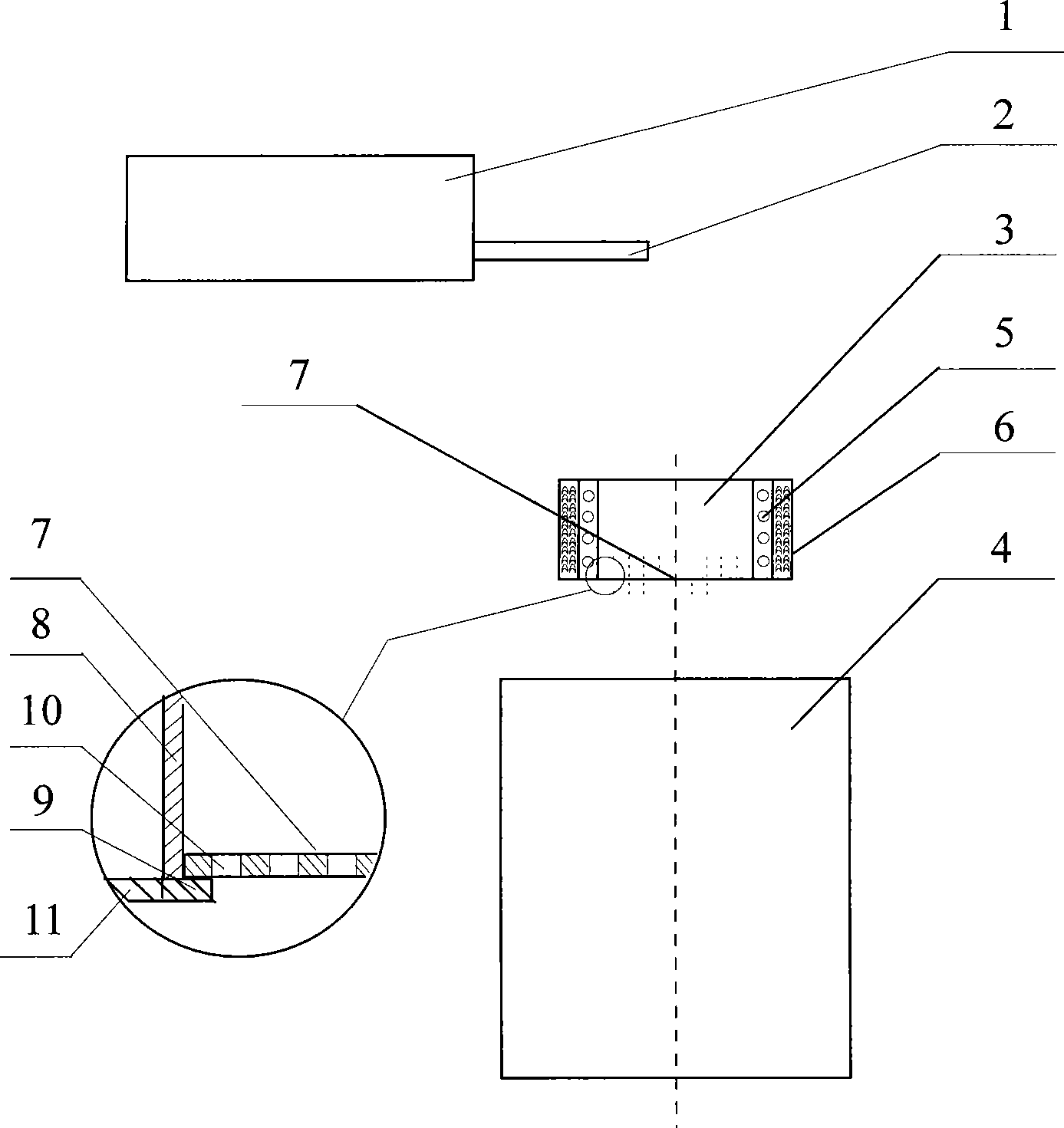

[0026] The single-phase salt-bath furnace transformer is 50 kVA, the electric melting furnace is 0.3×0.2×1.2 meters, the distance from the top of the nozzle 3 to the discharge port 2 is 0.2 meters, the distance from the bottom to the prilling tower 4 is 2.0 meters, and the diameter of the nozzle hole 10 is 0.003 meters. Add 5.0 kg of a mixture of selected magnetite, alumina, potassium nitrate, and calcium carbonate with a mass ratio of 100:3:1.6:3.2, 3.421 kg out of the furnace, and flow it into a nozzle preheated to 500-800°C to obtain The finished product (diameter greater than 0.002 meters) is 2.98 kg, the finished product yield is 87.1%, the spherical coefficient is 0.98, the mechanical strength is 308N / piece, and the activity and mechanical strength meet the requirements of industrial use.

Embodiment 2

[0028] Three-phase salt bath furnace transformer 100 kVA, electric melting furnace Φ1.0×0.4 meters, the distance from the top of the nozzle 3 to the discharge port 2 is 0.4 meters, the distance from the bottom to the liquid surface of the cooling pool 4 is 12.0 meters, and the nozzle holes are 10 0.005 meters in diameter, plus 100.0 kg of a mixture of selected magnetite, iron, aluminum oxide, potassium nitrate, calcium carbonate, and magnesium oxide with a mass ratio of 100:32:2.85:1.9:4.7:1.1, and 71.3 kg out of the furnace. Flow into the nozzle preheated to 200-300°C to obtain 60.82 kg of finished product (diameter greater than 0.002 m), the yield of finished product is 85.3%, the spherical coefficient is 0.94, and the mechanical strength is 278N / piece. The activity and mechanical strength of the product meet the requirements of industrial use.

Embodiment 3

[0030] The single-phase salt-bath furnace transformer is 50 kVA, the electric melting furnace is 0.3×0.2×1.2 meters, the distance from the top of the nozzle 3 to the discharge port 2 is 0.3 meters, the distance from the bottom to the prilling tower 4 is 5.0 meters, and the diameter of the nozzle hole 10 is 0.004 meters. Add 5.0 kg of Fischer-Tropsch synthesis catalyst prepared by the precipitation method, 3.3 kg out of the furnace, and flow into the nozzle preheated to 400-600 ° C in advance to obtain 2.82 kg of finished product (diameter greater than 0.002 m), the yield of finished product is 85.5%, the spherical coefficient 0.96, mechanical strength 298N / grain, activity and mechanical strength meet the requirements of industrial use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com