Lost foam casting-penetrating method for improving heat resistance of gray cast-iron based casting surface

A technology of lost foam casting and gray cast iron, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., which can solve the problems of complex equipment, high production costs, and large environmental pollution, and achieve the effect of improving heat resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is described in detail below in conjunction with accompanying drawing:

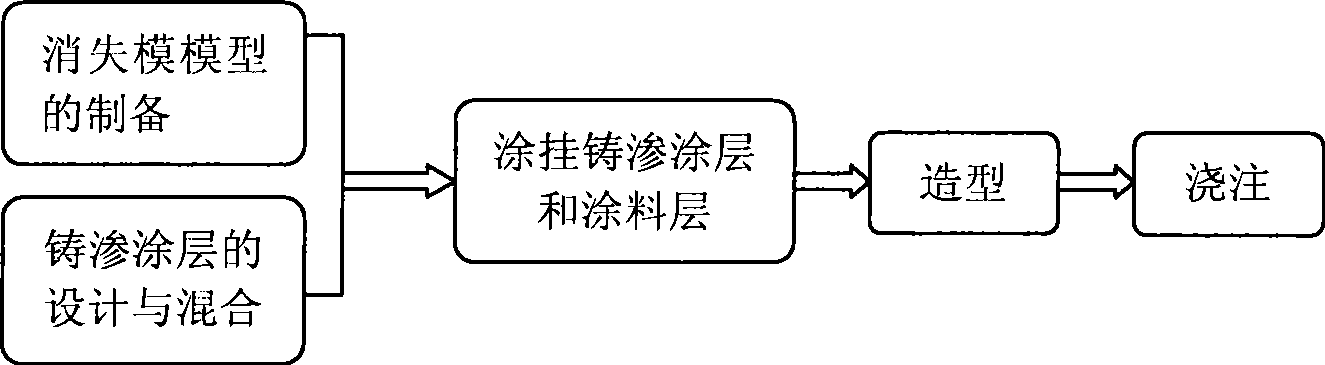

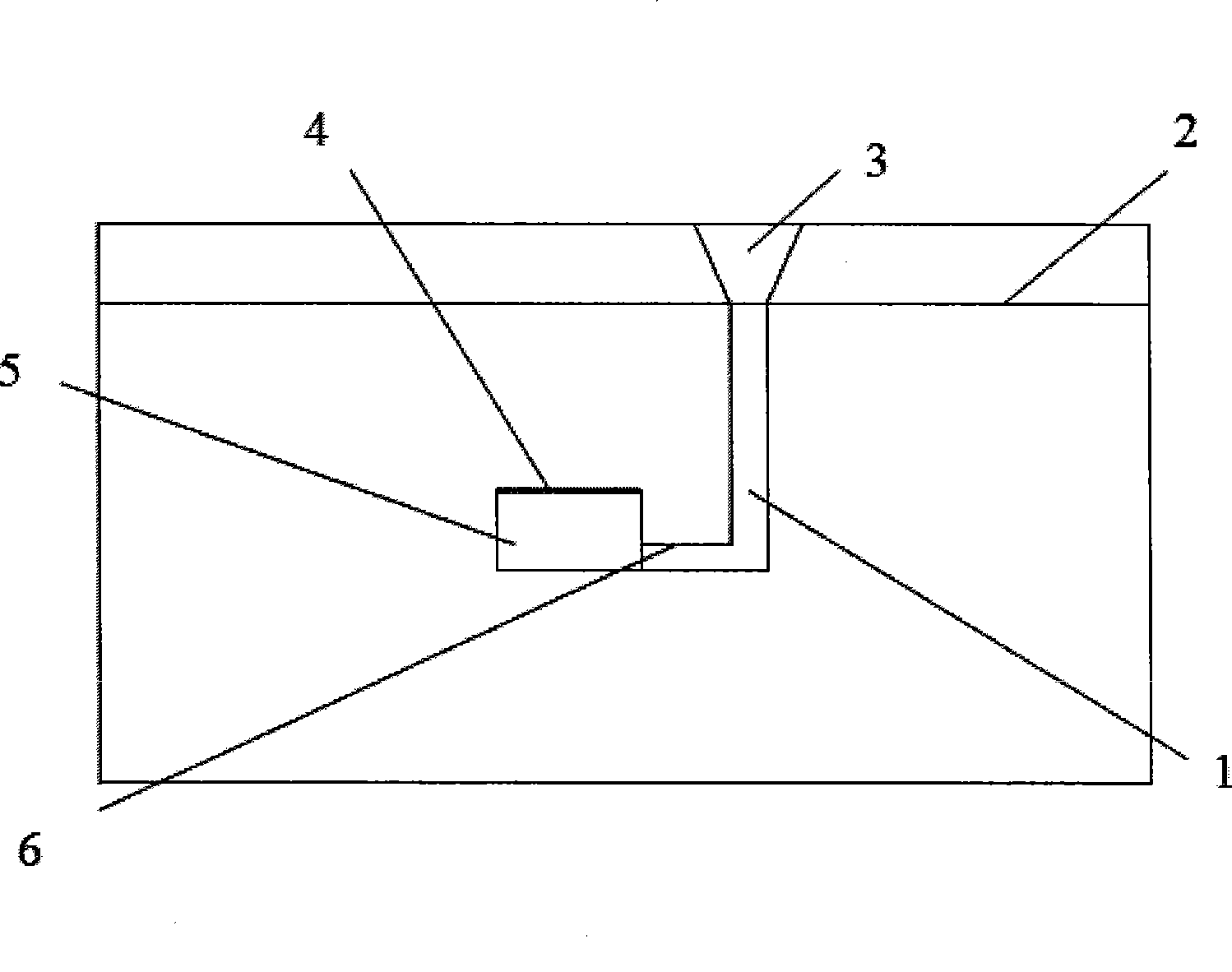

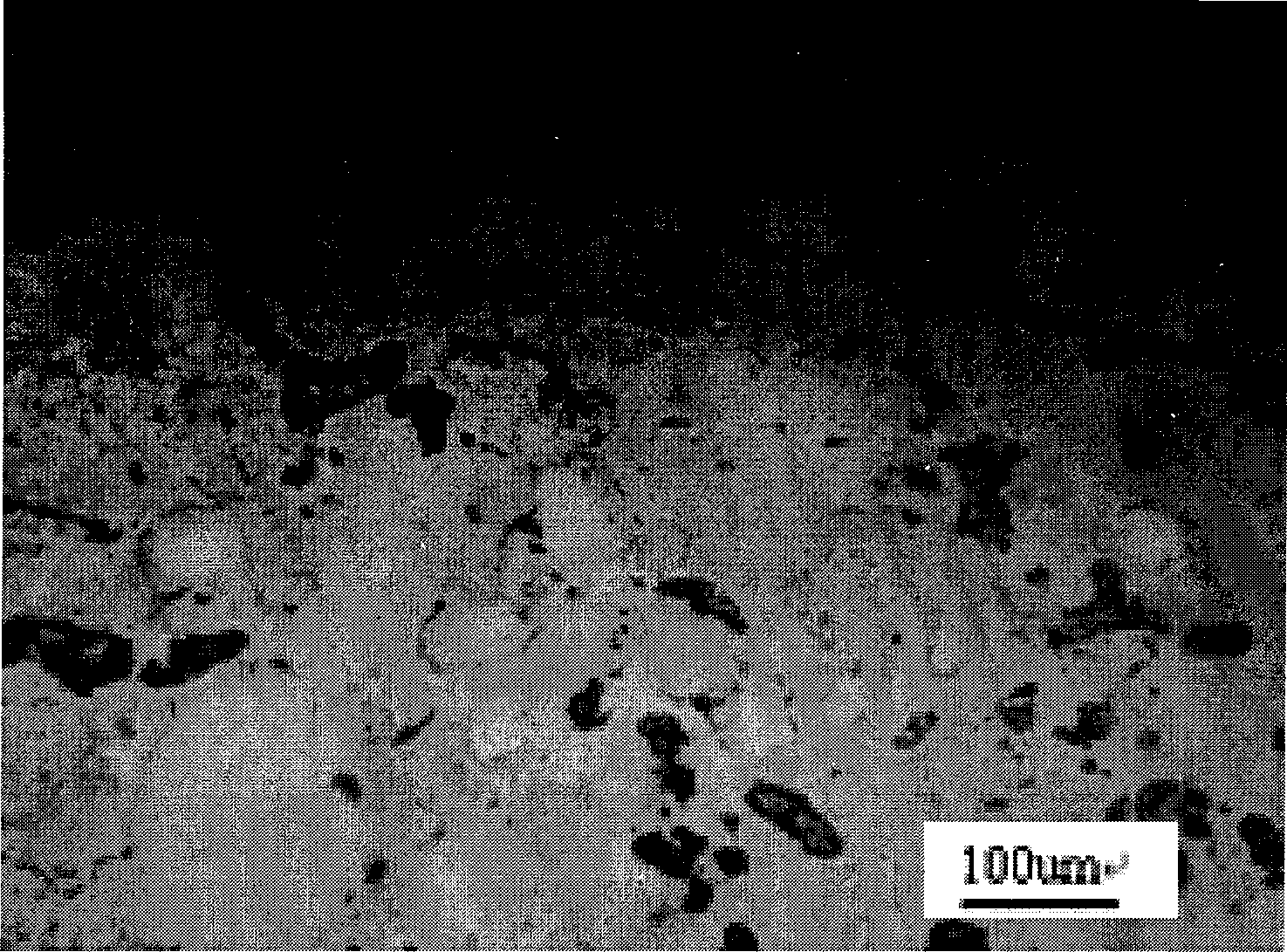

[0059] The lost foam casting infiltration method is to coat a layer of cast infiltration coating and a layer of paint on the corresponding surface of the foam plastic model processed into the required shape, and bury it in the sand after drying, and pour directly to vaporize the foam plastic model The liquid metal is drained through the paint layer to fill the cavity and form a casting.

[0060] The lost foam casting infiltration method is a promising modern casting method, which can meet the requirements of mass production of high-precision castings. The only difference between this method and the box casting method is that the box casting method uses molding sand to make the model. The lost foam casting infiltration method is to make a model of the shape of the required part from the foam plastic, bury the foam plastic model in the sand and pour it without a core and a rise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com