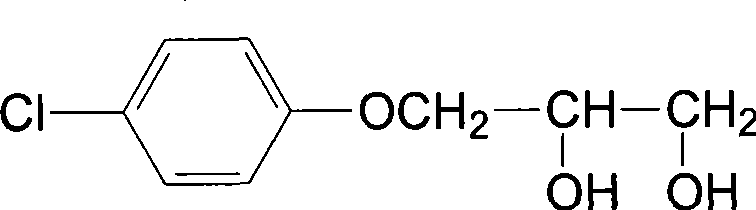

Method for preparing medical compound chlorphenesin

A technology of chlorphenesin and compounds, which is applied in the field of preparation of the pharmaceutical compound chlorphenesin, can solve problems such as strong anesthesia, difficult safety control, and flammability, and achieve simple operation, good non-toxic safety, and raw materials low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

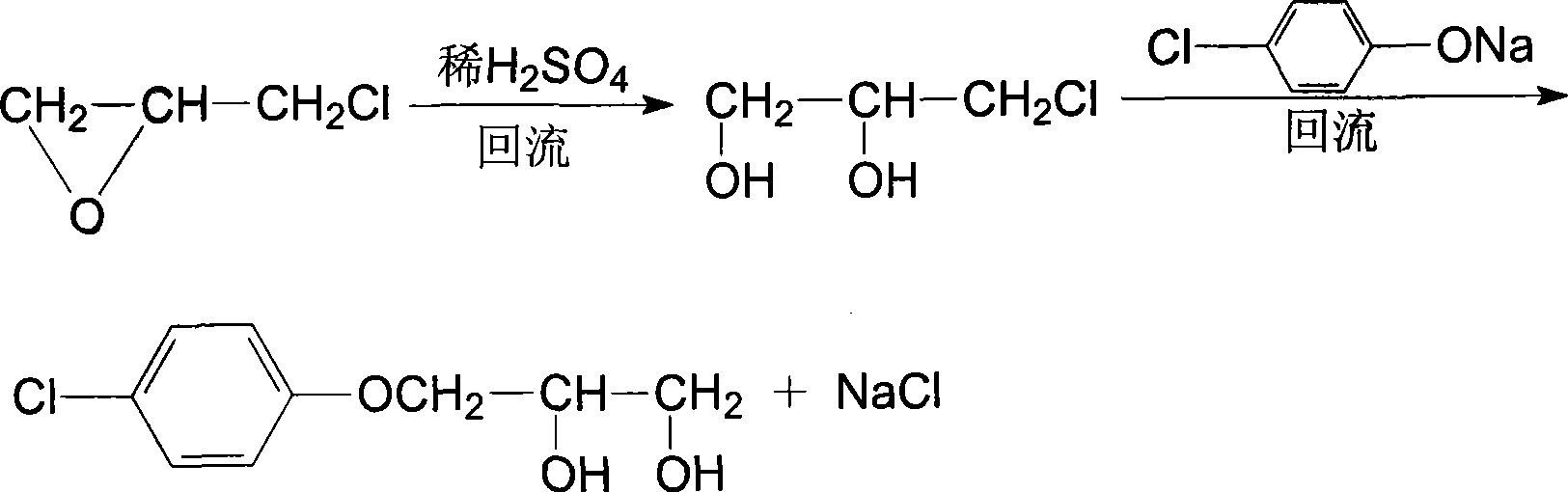

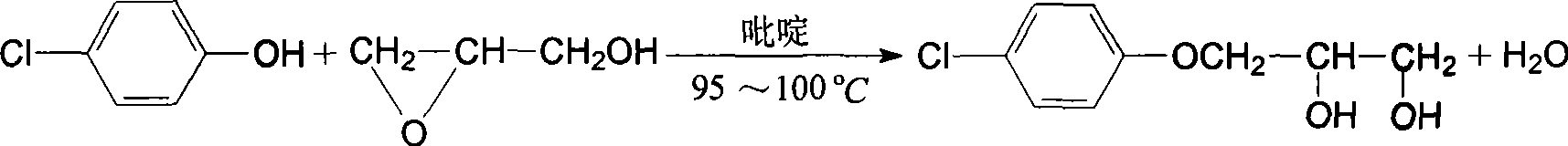

Method used

Image

Examples

Embodiment 1

[0025] Put epichlorohydrin (100g) into the reaction bottle, stir, put in 200ml dilute sulfuric acid, heat to 100-105°C, reflux for 1 hour, cool down to 80°C, add p-chlorophenol (128.6g) and 37% hydrogen Sodium oxide aqueous solution, heated to 105-115°C, alkaline reflux reaction for 1 hour, cooled to 75°C, neutralized by adding appropriate amount of dilute hydrochloric acid, controlling pH 5.5-6.5, poured into a separating funnel, standing still, layered, the lower layer The oil was crystallized in stirred chloroform, frozen for 4 hours, filtered with suction, dried at 40-45°C for 2 hours, and dried at 60°C for 6 hours, with a melting point of 77°C to obtain 182 grams of chlorphenesin. The method of recovering chloroform: wash with water 1-2 times, let stand, separate layers, collect the chloroform layer, which can be recycled.

Embodiment 2

[0027] Put epichlorohydrin (100g) into the reaction bottle, stir, add dilute sulfuric acid 200ml, heat, reflux for 1 hour, cool down to 80°C, add p-chlorophenol (128.6g) and 37% sodium hydroxide aqueous solution, heat , alkaline reflux reaction for 1 hour, lower the temperature to 75°C, add an appropriate amount of dilute hydrochloric acid to neutralize, control the pH to 5.5-6.5, pour it into a separatory funnel, let it stand, separate layers, put the lower layer of oil into the stirred ethanol-water solution to analyze crystallization, freezing for 8 hours, suction filtration, and drying of the filter cake (it is advisable to gradually increase the drying temperature in stages), with a melting point of 77±2°C to obtain 183g of the product.

[0028] Refining method: use ethanol-water (2:8 or 3:7) 2-6 times as the refining solvent, put in the crude product, ethanol-water, activated carbon, heat and reflux for 30-45 minutes, heat filter, and the filtrate drops to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com