Pharmaceutical thermoplastic elastomer bottle stopper and preparation method thereof

A thermoplastic elasticity and body bottle technology, which is applied in the field of pharmaceutical thermoplastic elastomer bottle stoppers and its preparation, can solve the problems of high production energy consumption, difficulty in adapting to requirements, drug safety problems, etc., achieves improved mechanical properties and hardness, and is beneficial to industrial Production and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

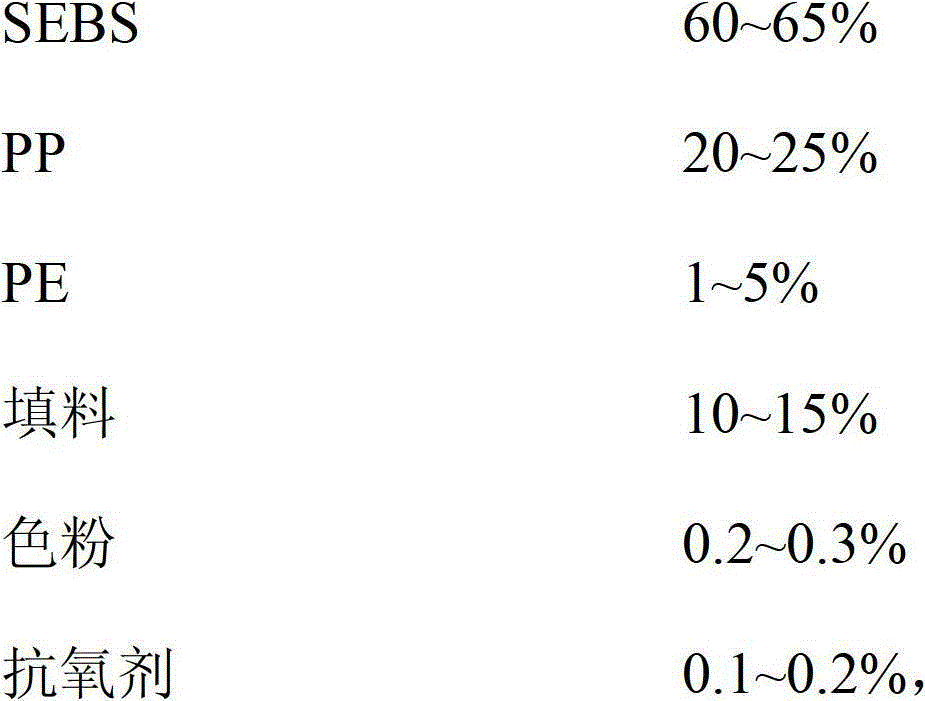

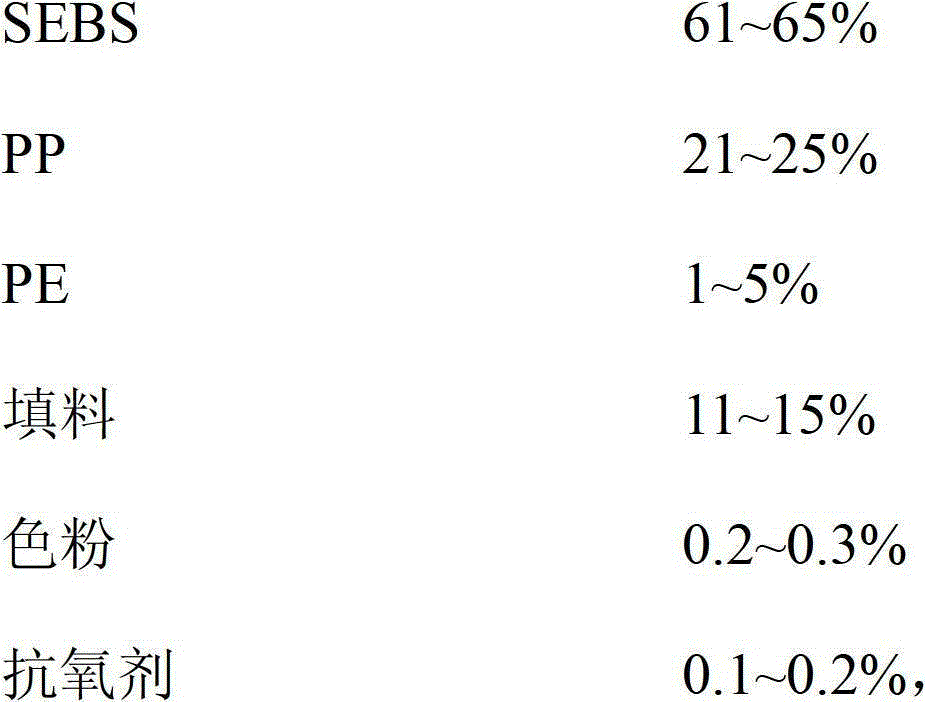

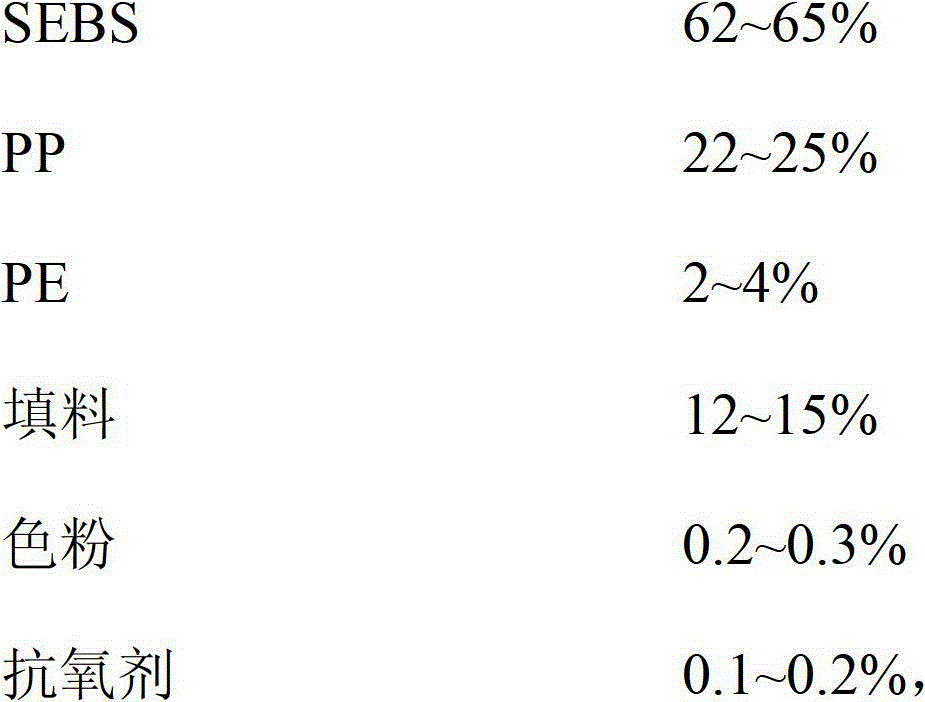

[0051] Table 1 shows the composition of the medicinal thermoplastic elastomer bottle stopper described in Examples 1-3 and the process parameters of the preparation method.

[0052] Table 1

[0053]

[0054] The preparation method of above-mentioned medicinal thermoplastic elastomer bottle stopper is:

[0055] Weighing according to the formula, stirring and mixing, extruding and granulating, then injection molding, siliconization, and packaging to obtain the medicinal thermoplastic elastomer bottle stopper.

[0056] Among them, the injection molding temperature and injection molding pressure are shown in Table 2.

[0057] Table 2

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com