Device for water-surface aquaculture engineering and construction method thereof

A water surface breeding and construction method technology, applied in the direction of botanical equipment and methods, biochemical equipment and methods, biochemical cleaning devices, etc., to achieve the effect of saving piles and pile cables, reducing damage, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

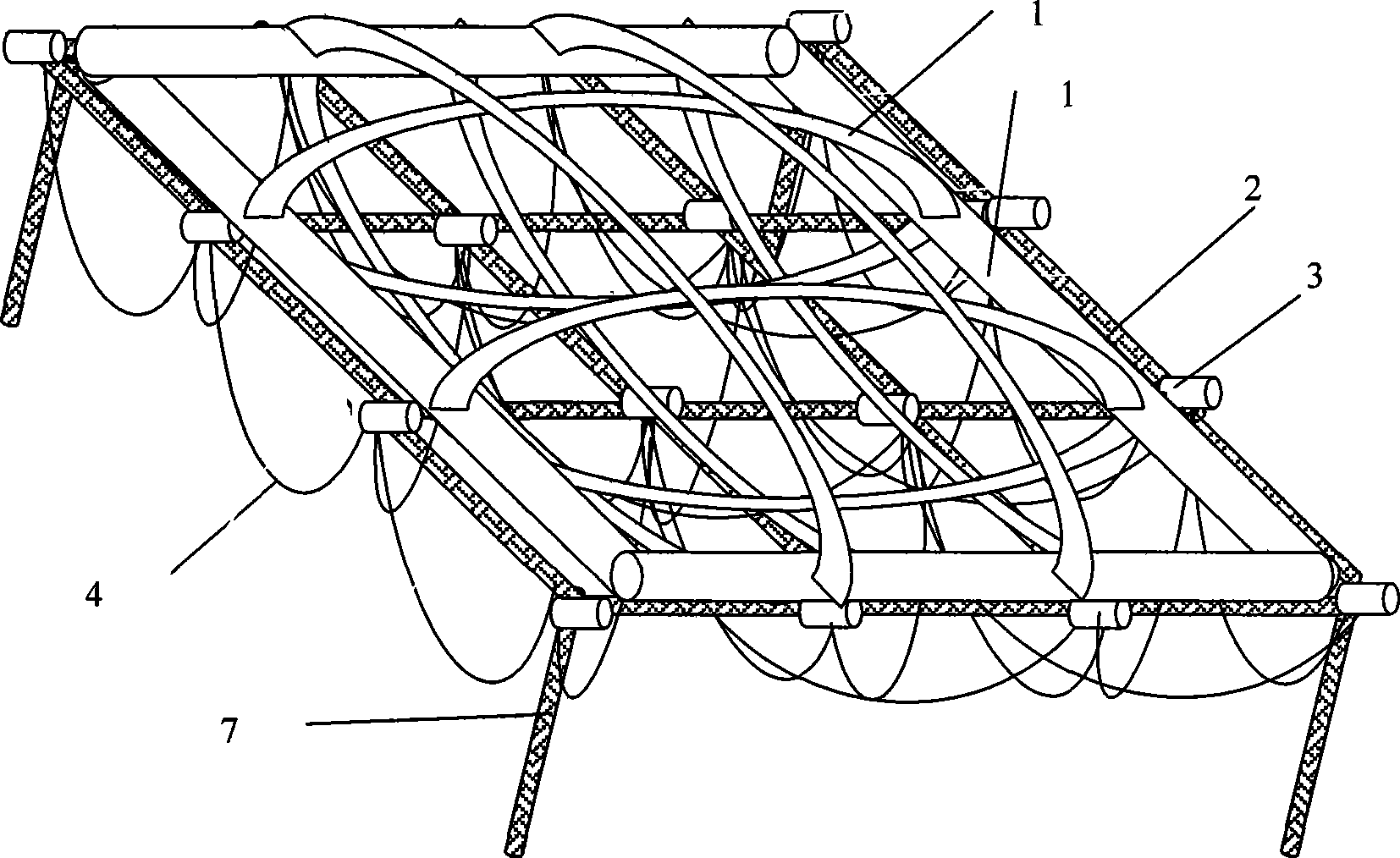

Embodiment 1

[0075] Example 1: Construction of a floating support structure with a "floating tube" pipe section and a "live bottom" cable bottom bracket section. The pipe part is connected by PPR hot-melt pipe through hot-melt sealing, and the middle ventilation is used as a part of the load-bearing floating pipe and gas distributor; the interval uses a wire-reinforced polyvinyl chloride hose as an elastic sleeve to connect the PPR pipe. The support part of the "live bottom" bottom bracket is made of fiber reinforced polyvinyl chloride pipe with a cable jacket, and the floats arranged in a grid form form a strip network structure; the pile cable is made of fiber reinforced polyvinyl chloride material, with a diameter of 10-12 mm (1000 -1500 shares), the length is about 2 to 3 times of the water depth at high tide, and the floats are glass fiber balls or plastic balls; the piles are buried in sand and mud on the seabed. The structural shape of the pipeline units perpendicular to the water s...

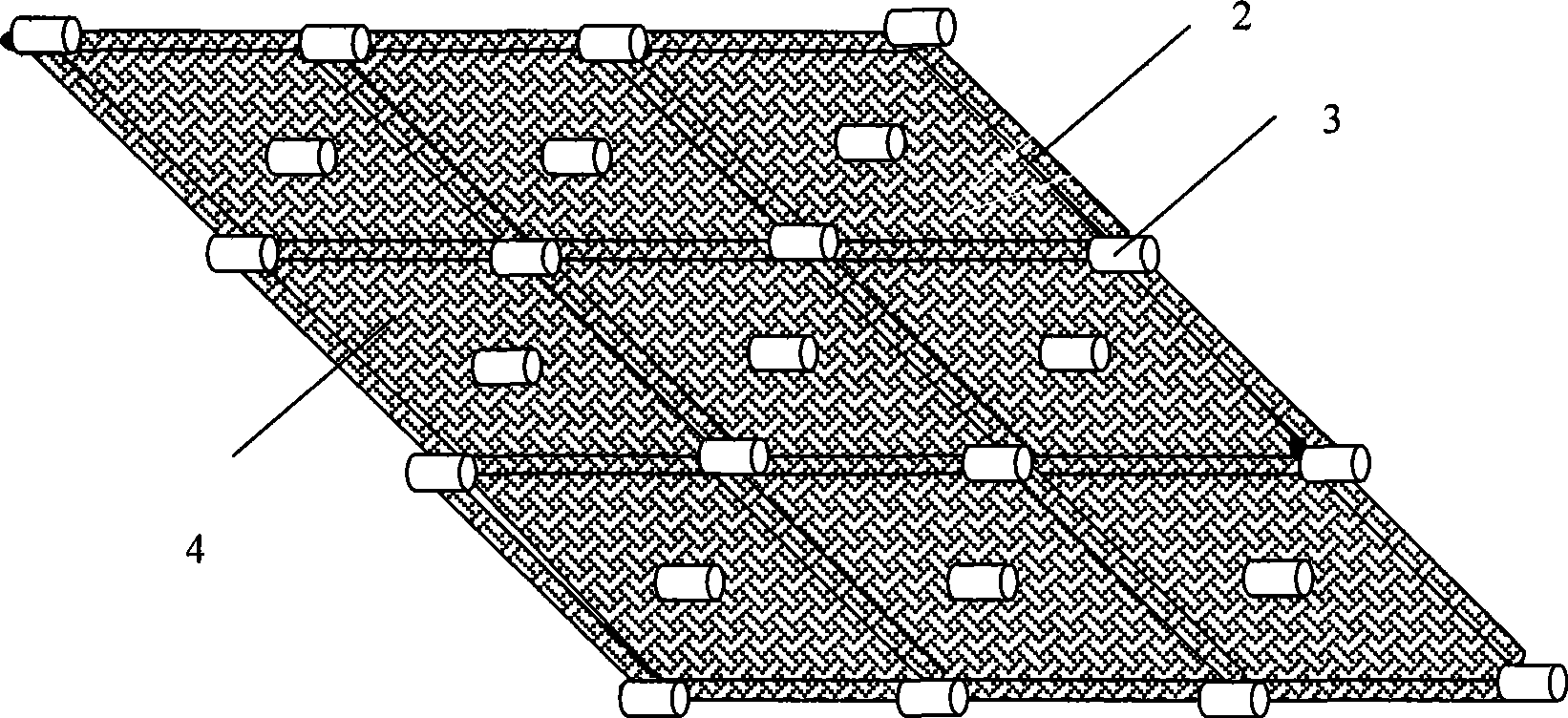

Embodiment 2

[0076] Example 2: The part of the self-floating pipeline is connected by PPR hot-melt pipe through hot-melt sealing, and the middle ventilation is used as a load-bearing floating pipeline and a gas distributor. The shape of the pipe support unit structure is circular, and it is repeatedly arranged in parallel along the water surface and connected to each other to form a grid-like pipe support structure, and elastic connection or movable connection can be used between them. A plurality of light-transmitting round plastic boxes are used as culture containers and are located in the middle of the round pipe support. The top wall of the plastic box culture container can be separated from the bottom wall for easy cleaning and installation. The floating rope structure adopts the form of ropes and chains to connect the culture container and the pipe support in a movable manner, and bears the bottom of the culture container; different culture containers and horizontal pipe supports ris...

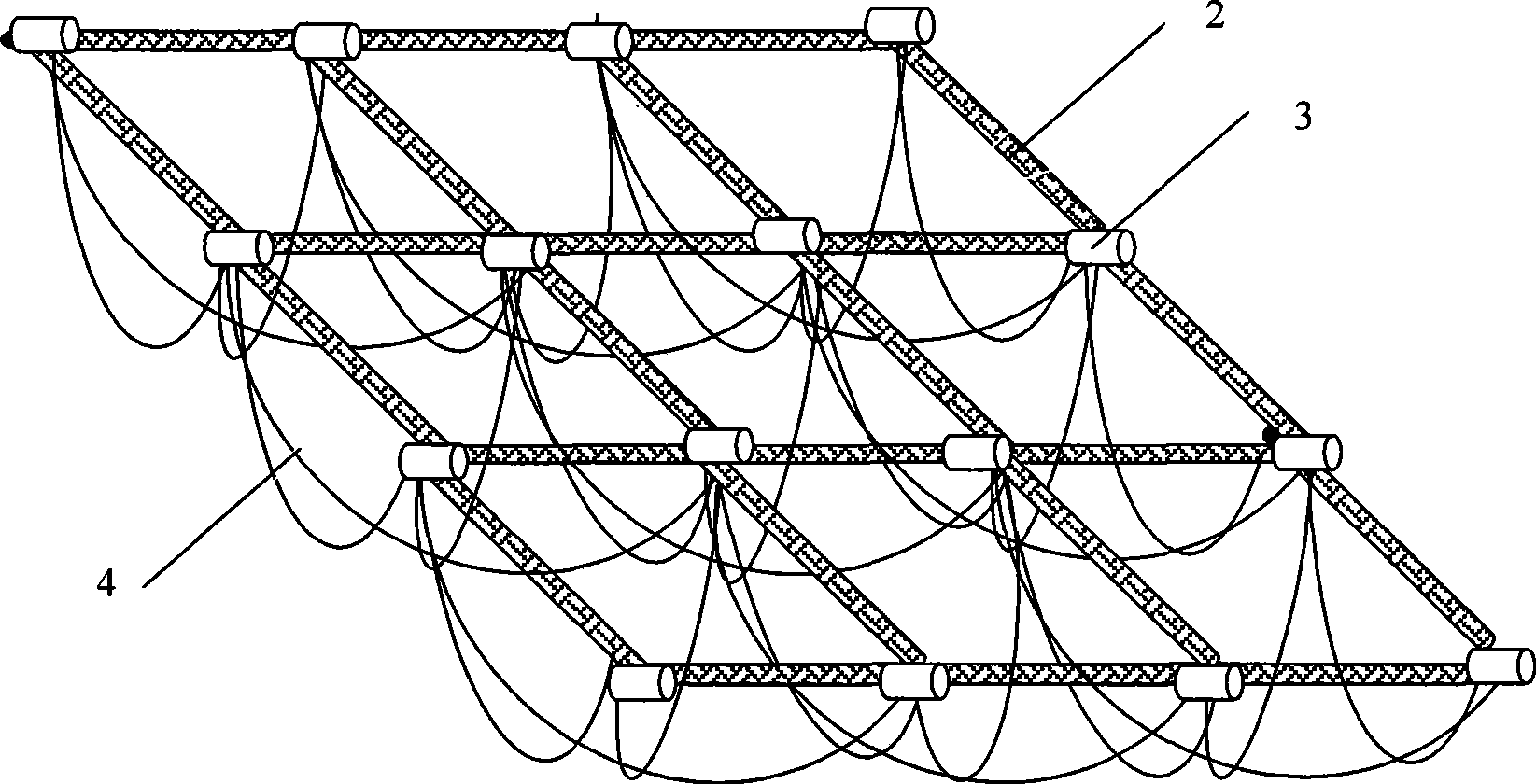

Embodiment 3

[0077] Example 3: The metal wire is used to strengthen the ventilation in the middle of the polyvinyl chloride pipe as the load-bearing floating pipe and gas distributor in the pipe support part. The pipe unit structure that is repeatedly arranged perpendicular to the water surface is shuttle-shaped, and is repeatedly arranged along the direction parallel to the water surface and connected to each other to form a tubular pipe support structure. The streamlined structure of this structure on the water surface can support the top of the culture container higher than the water surface, which is convenient for ventilation and maintains the transparency of the top; Regularly arranged groove structure. The streamlined structure under the water surface can be drilled as a part of the gas distributor; it can also be connected to the air stone through the air nozzle and installed on the arc top pipe support on the water surface as a gas distributor. The top light-transmitting plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com