Synthetic process of high temperature resistant epoxy vinyl ester resin

A technology of epoxy vinyl ester and synthesis process, which is applied in the field of synthesis process of high temperature resistant epoxy vinyl ester resin to achieve the effects of high heat distortion temperature, good mechanical properties and improved labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

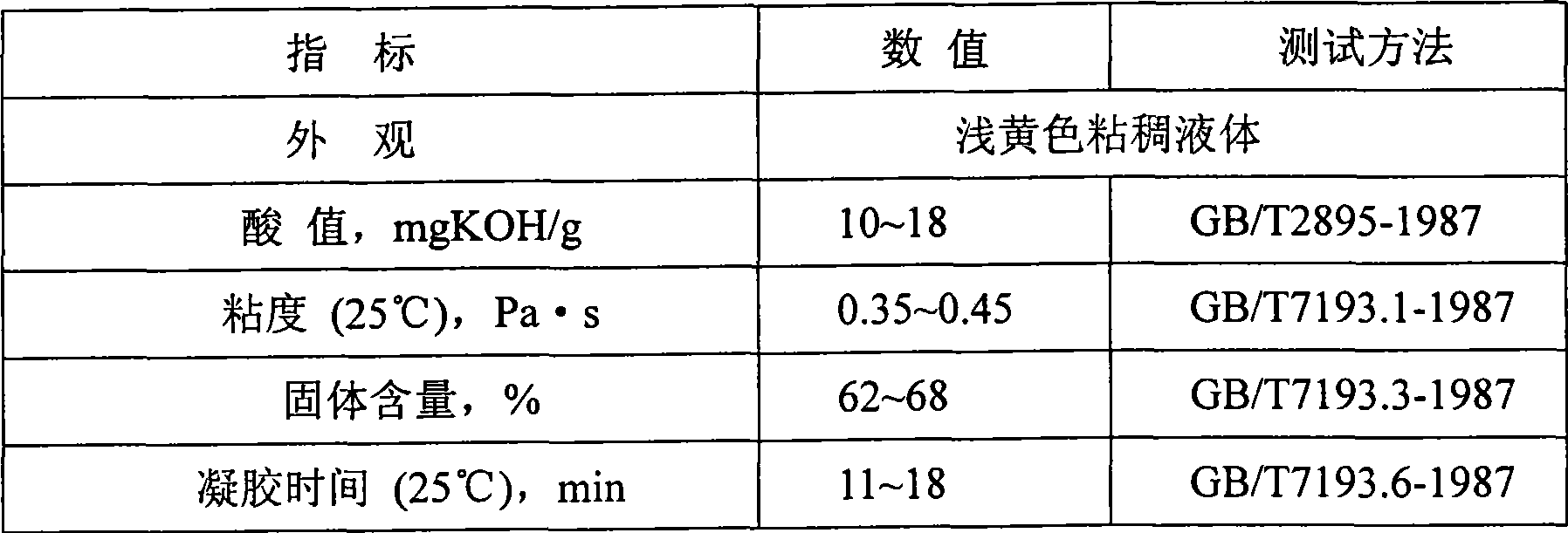

Image

Examples

Embodiment 1

[0023] 340 g of linear phenol-formaldehyde epoxy resins, 150 g of methacrylic acid, 1.2 g of benzyldimethylamine, and 0.15 g of p-phenol were charged into the reactor. The temperature was gradually raised to 130° C. under the condition of feeding nitrogen, and the temperature was maintained until the measured acid value was less than 30 mgKOH / g. Cool down to below 110°C, add 0.05g of tert-butylcatechol and 260g of styrene, stir thoroughly, and finally cool to room temperature, filter to obtain a light yellow viscous liquid.

Embodiment 2

[0025] Four (p-hydroxyphenyl) ethane tetraglycidyl ether epoxy resin 340g, acrylic acid 115g, benzyltrimethylammonium chloride 0.95g, methyl p-phenol 0.10g drop into the device shown in example 1, pass into Under the condition of nitrogen, the temperature is gradually raised to 120°C, and the temperature is maintained until the measured acid value is less than 30mgKOH / g. Cool down to below 110°C and add 0.05g of tert-butylhydroquinone, 0.08g of copper naphthenate solution, 210g of styrene, and 40g of divinylbenzene, stir thoroughly, and finally cool to room temperature and filter to obtain a light yellow viscous liquid.

Embodiment 3

[0027] 340g of pyroglucinol triglycidyl ether epoxy resin, 170g of crotonic acid, 1.4g of benzyltriethylammonium chloride, 0.18g of tert-butyl hydroquinone are dropped into the device shown in example 1, pass into Under the condition of nitrogen, the temperature is gradually raised to 160°C, and the temperature is maintained until the measured acid value is less than 30mgKOH / g. Cool down to below 110°C, add 0.05g of copper naphthenate solution, 250g of styrene, 20g of diallyl phthalate, stir thoroughly, and finally cool to room temperature, filter to obtain a light yellow viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com