Three light wave transversal shearing interference apparatus and method for extracting differential phase

A technology of transverse shearing and differential phase, which is applied in the device of three-wave transverse shearing interference, extracts the field of differential phase, and can solve the problems of difficult to play spatial light modulator, vibration of optical system, low control precision, etc., and achieve environmental interference Effects of insensitivity, low coherence requirements, and high regulation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

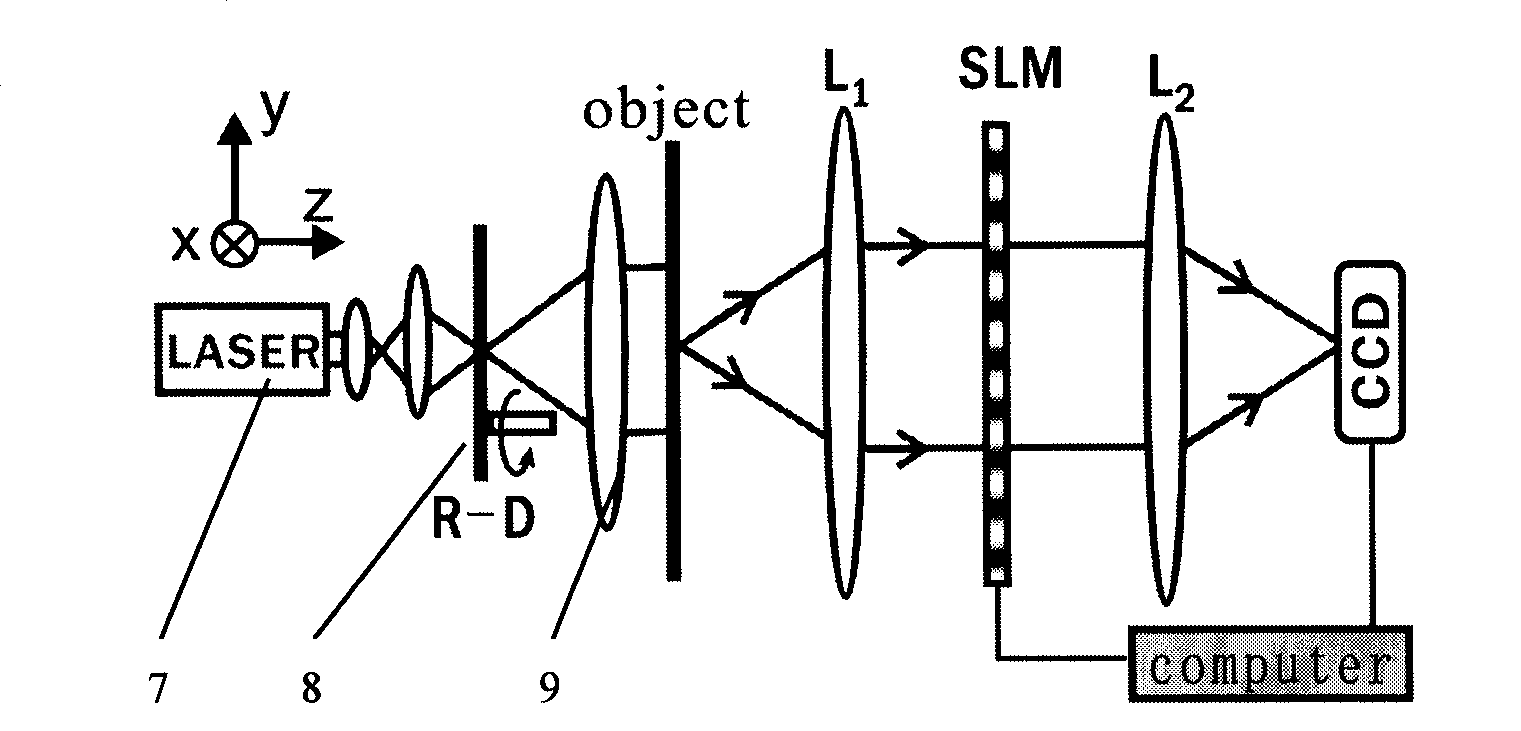

[0030] Such as figure 2 As shown, the complete technical scheme of the three-wave dynamic transverse shearing interference generating device of the present invention is as follows: the light source we use is a He-Ne laser 7 with a wavelength of 632.8 nm, and the spatial light modulator 4 is a transmissive liquid crystal from Sony. The spatial light modulator has a number of pixels of 1024×768 and a pixel size of 18 microns x 18 microns. A piece of rotating ground glass 8 is located on the front focal plane of the lens 9 to reduce the spatial coherence of the illumination light wave so as to reduce the effect of speckle. The plane light wave generated by the lens 9 illuminates the object to be measured, the confocal lenses L1 and L2 form a 4f system, and the spatial light modulator (SLM) is placed on the confocal surface of the 4f system. The computer is connected to the spatial light modulator and the charge coupled device (CCD) at the same time, which can control the display of ...

Embodiment 2

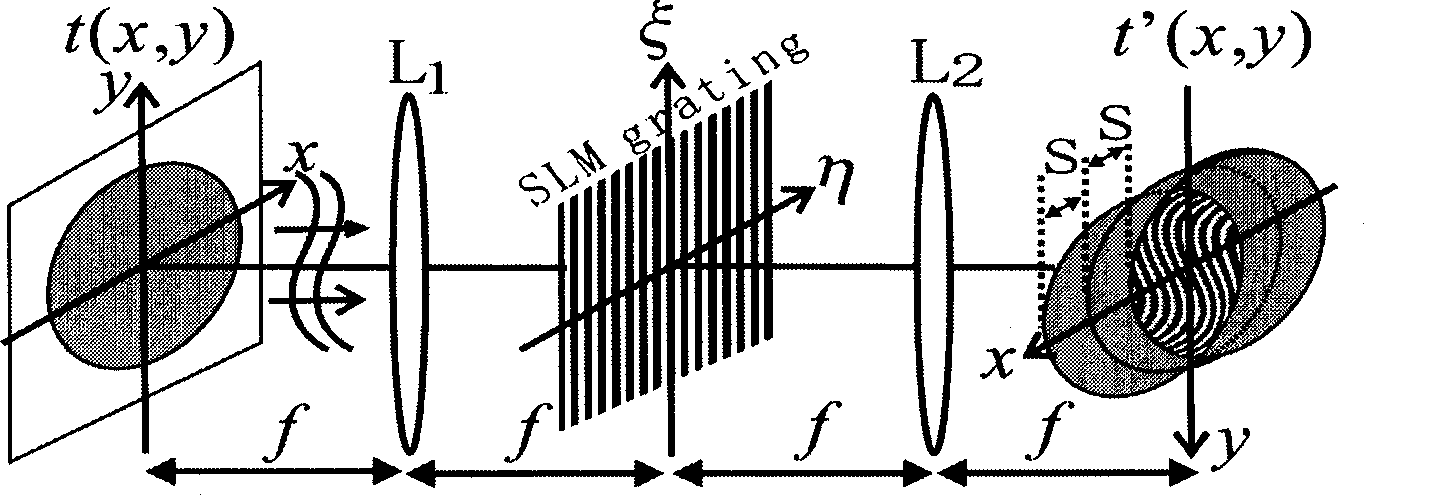

[0035] according to figure 1 The principle is to build a 4f optical system, and the specific experimental system built based on this is such as figure 2 Shown. In order to verify the effect of generating three light waves, we add a small light hole on the object plane. The experimental effects of three beams of light generated when the grating line direction is along the y direction and the x direction are respectively provided without grating, and the image is collected by CCD. Figure 4 The first column in the middle shows the grating loaded on the spatial light modulator. When the grating is not added, after two Fourier transforms, it is still an image of a small hole spot. Figure 4 The second column in the middle shows the output effect after loading the grating, forming three staggered light spots in the x direction and y direction.

Embodiment 3

[0037] according to figure 1 Build a 4f optical system, and build a specific experimental system based on it such as figure 2 Shown. A test lens is placed on the input surface of the 4f system to generate the phase distribution of the spherical wavefront to be measured. The display on the spatial light modulator is as follows Figure 5 For the two gratings shown in the first column, the three-wave transverse shearing interference pattern with the shearing direction along the x direction and the y direction is observed on the output surface, as Figure 5 As shown in the second column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com