Production of micro- and nanopore mass arrangements by self-organization of nanoparticles and sublimation technology

A nanopore and particle technology, which is applied in the field of preparing micropores and nanopore group arrays through nanoparticle self-organization and sublimation technology, can solve the problem of high cost, large area micropore and nanopore group arrays limited by optical lithography, long issues of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Fabrication of well group arrays on glass substrates

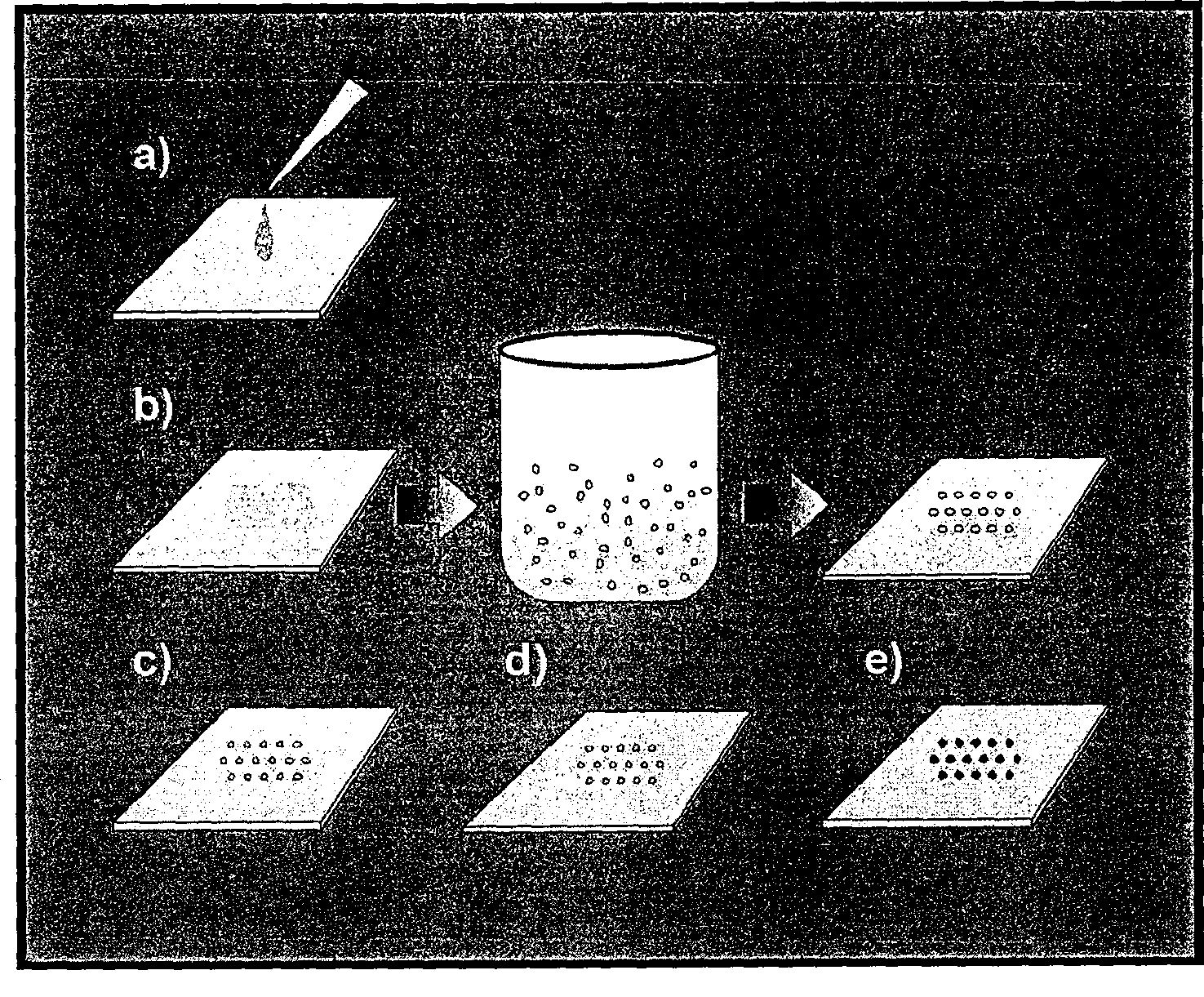

[0040] A 10% by weight solution of bovine serum albumin (BSA) in water was provided on a clean small coverslip. After an exposure time of 10 minutes, an approximately 6 nm thick layer of BSA was adsorbed on the surface. The substrate was washed with Milli-Q-water in a glass beaker, then blown dry with nitrogen ( figure 1 a).

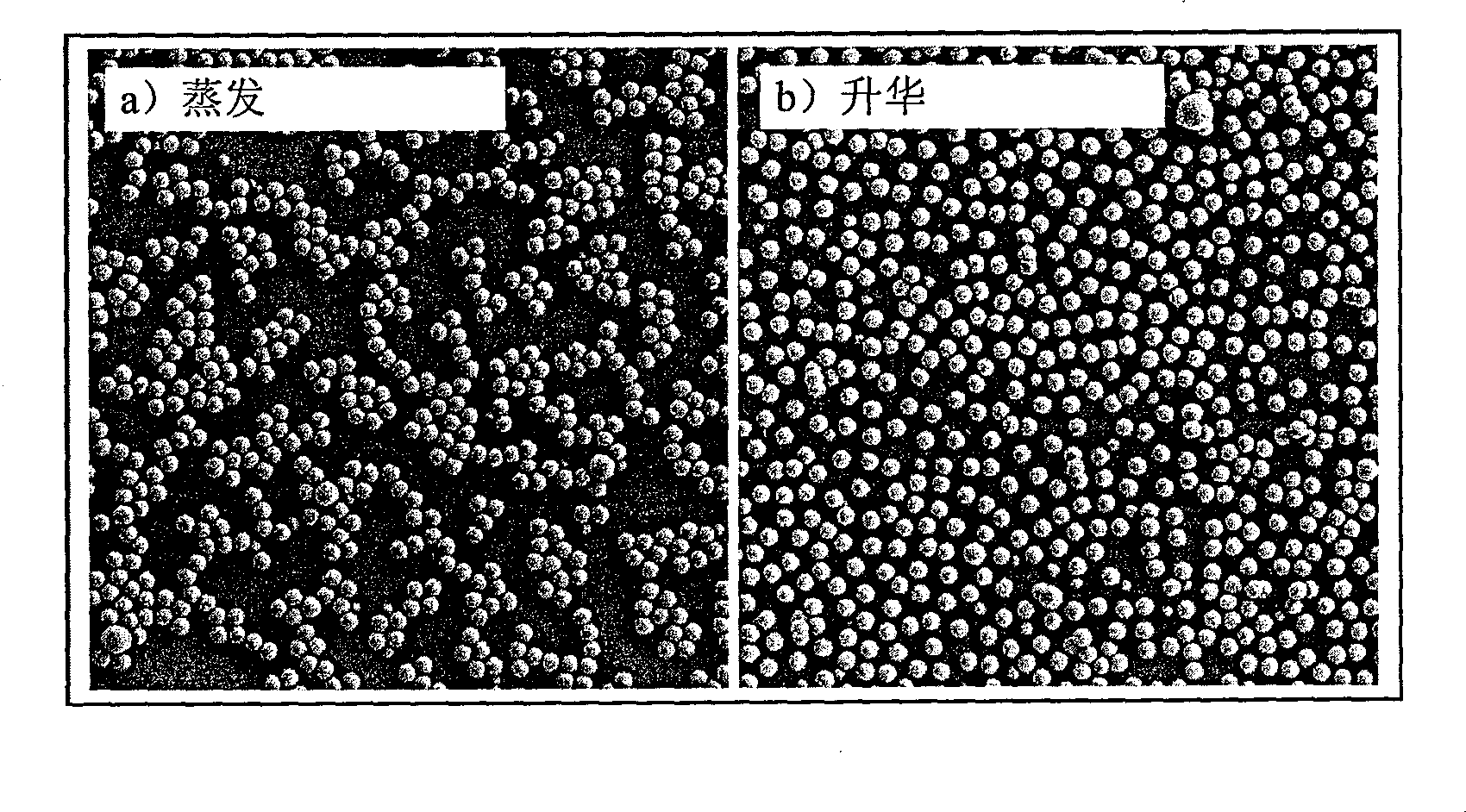

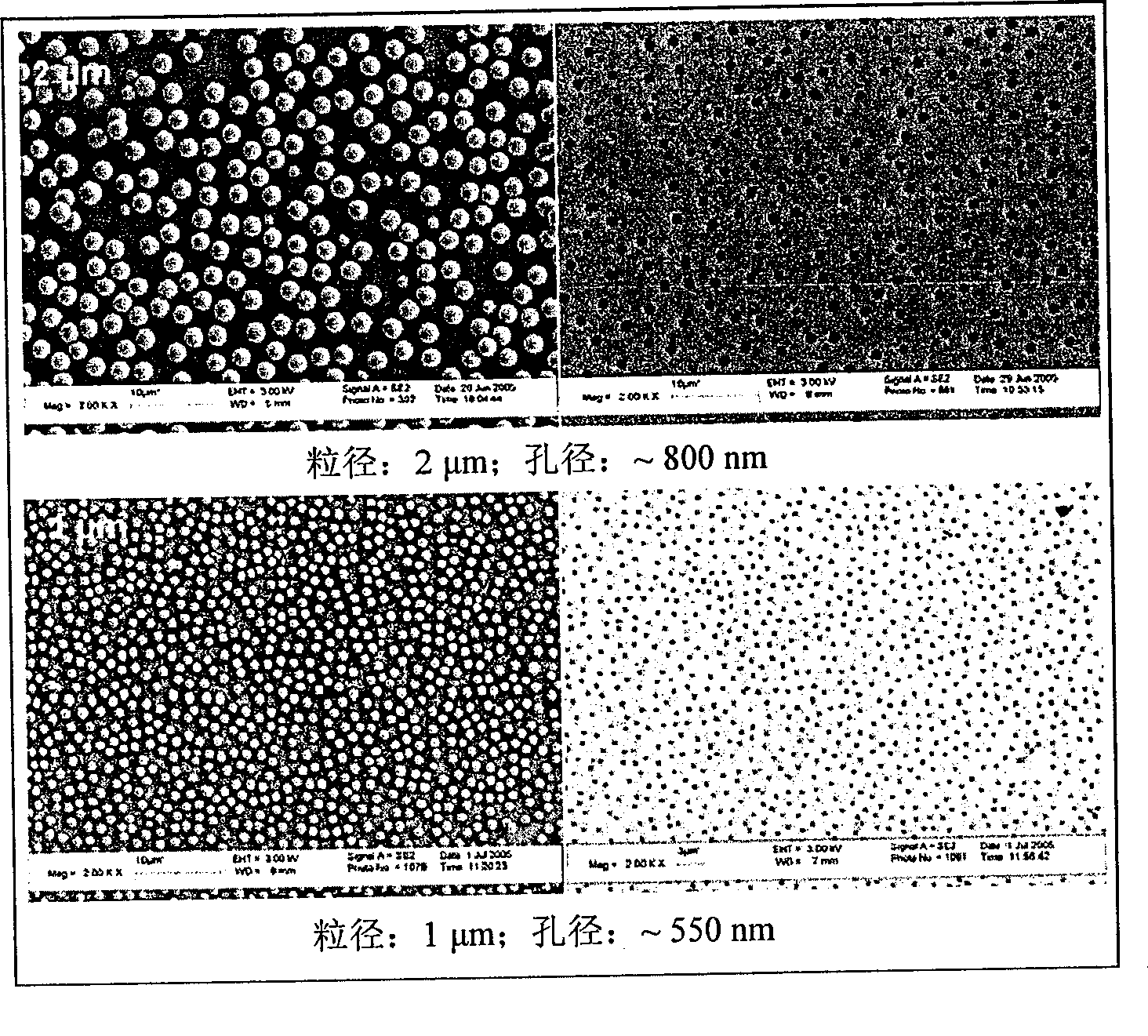

[0041] The functionalized small glass plate was dipped into a dispersion of polystyrene particles in water at a concentration of 2.5% by weight ( figure 1 b). Due to the electrostatic interaction between the BSA film and the sulfate groups on the surface of the particles, adsorption only occurred on the substrate area prepared with the adhesion promoter. The modified surface was washed with water to remove excess unattached particles, and the still wet sample was immersed in liquid nitrogen. The short-range ordering of particles in liquids due to mutual electrostatic repulsion is preserve...

Embodiment 2

[0045] Functionalizing substrates with organosilanes

[0046] Through 3-aminopropyltriethoxysilane (NH 2 (CH 2 )Si(OC 2 h 5 ) 3 ) to functionalize the substrate surface.

[0047] First, the glass substrate was treated with Caro's acid (H 2 o 2 / H 2 SO 4 (1:3 ratio) for 30 minutes, followed by Milli-Q-water and methanol in an ultrasonic bath. By dipping the substrate in 290ml methanol, 3ml aminosilane, 5ml H 2 Silanization of the surface was carried out in O and 18 μl of glacial acetic acid with a reaction time of 12 hours. Finally, the small glass slide was washed several times with methanol and dried (D. Cuvelier, O. Rossier, P. Bassereau, P. Nassoy, Eur. Biophys. J., 2003, 32, 342-354).

[0048] Incorporation of monolayers of different organosilane derivatives has been demonstrated on substrates such as silicon, alumina, quartz, glass, mica, zinc selenide, germanium oxide and gold (A. Ulman, Chem. Rev., 1996 , 96, 1533-1554).

[0049] The functionalized substrat...

Embodiment 3

[0051] Functionalization of silica particles with organosilanes

[0052] Inorganic silica particles were functionalized with triethoxysilyl-propyl-succinic anhydride (TESPSA). Silanization was achieved by incubating the particles in a 10% solution of TESPSA in toluene for 16 hours (G.K. Toworfe, R.J. Composto, I.M. Shapiro, PDucheyne, Biomaterials, 2006, 27(4), 631-642). The particles were separated from the reaction solution by centrifugation and sonication in several washing steps and washed with toluene and water. Finally, the carboxylated particles were resuspended in Milli-Q-water.

[0053] A 0.1% solution of polyethyleneimine (PEI) in water was coated on the cleaned glass surface. After an exposure time of 10 minutes, a thin PEI film was adsorbed on the surface. The substrate was washed and dried in a beaker of Milli-Q-water. Due to the amino groups on the substrate surface and the SiO 2 Attractive interactions between the carboxyl groups of the particles enable par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com