Simple thermal expansion method for preparing thin graphene

A thin-layer graphene and thermal expansion technology, which is applied to the simple thermal expansion preparation process of thin-layer graphene and the thermal expansion method for preparing thin-layer graphene, can solve complex steps, improve equipment cost, cost and production efficiency restricting the scale of graphene to reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

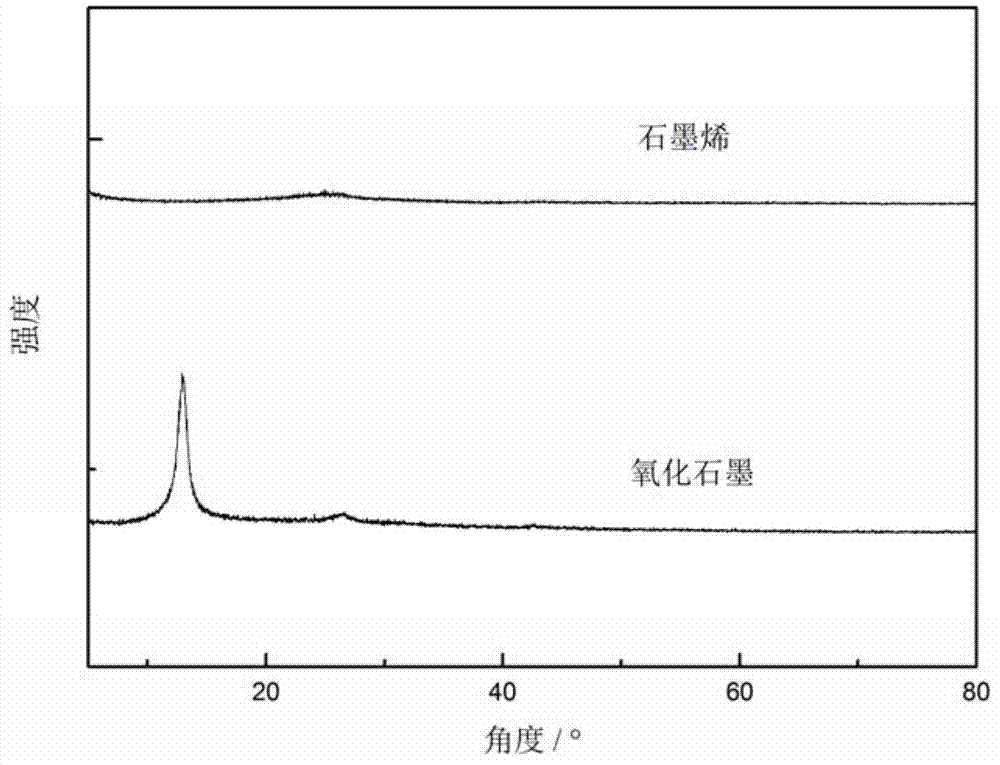

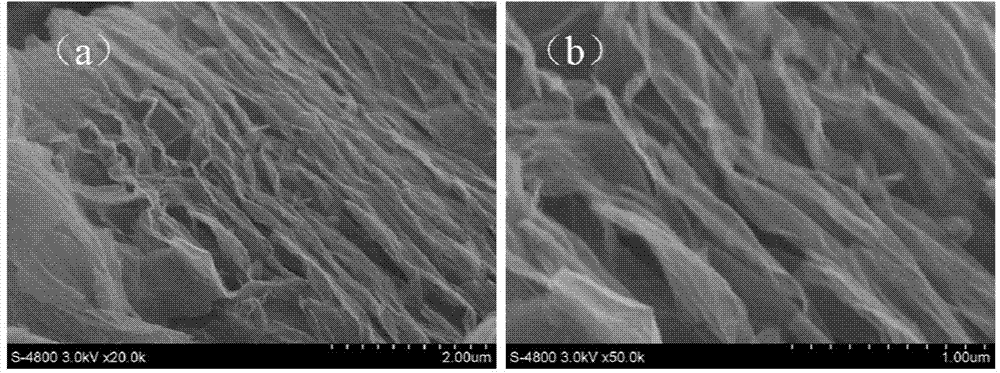

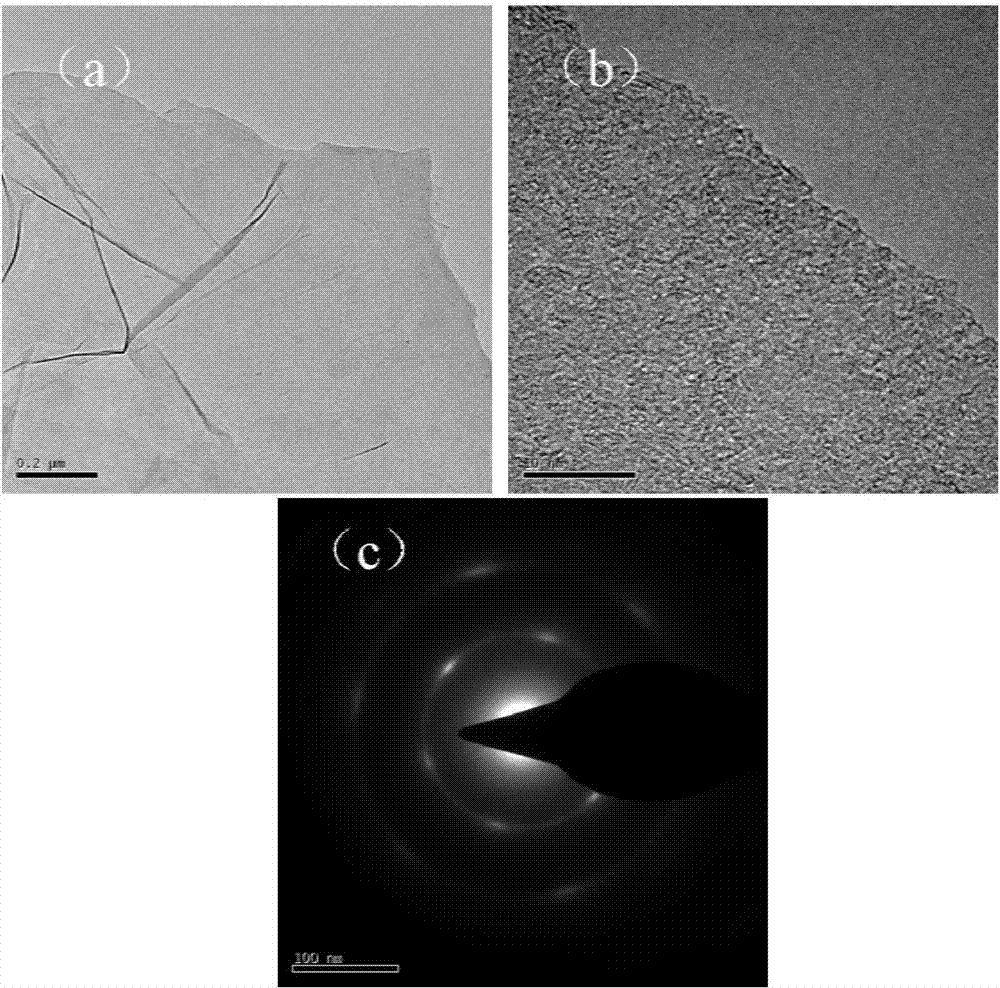

[0020] Using flake graphite as raw material, graphite oxide was obtained by Hummers method. After washing the obtained graphite oxide, dry the sample at 100°C in a blast drying oven to fully dry the sample and obtain pure graphite oxide powder after crushing; / min heated to 350°C; directly sprinkle 5g of the above-mentioned graphite oxide into the preheated furnace, make it heat up suddenly, complete the expansion of graphite oxide in an instant, and obtain thin-layer graphene powder.

Embodiment 2

[0022] Using artificial graphite as raw material, graphite oxide was obtained by Hummers method. After washing the obtained graphite oxide, dry the sample at 80°C in a blast drying oven to fully dry the sample and obtain pure graphite oxide powder after crushing; first, heat the box furnace to 350°C at 5°C / min The above-mentioned graphite oxide of 500g is directly sprinkled into the preheated furnace, makes it heat up suddenly, and completes the expansion of graphite oxide in an instant, and obtains thin-layer graphene powder.

Embodiment 3

[0024] Graphite oxide was obtained by Hummers method using graphite nano-sheets as raw materials. After washing the obtained graphite oxide, dry the sample at 120°C in a blast drying oven to make the sample fully dry and pulverize to obtain pure graphite oxide powder; / min heated to 250°C; directly sprinkle 50g of the above-mentioned graphite oxide into the preheated furnace, make it heat up suddenly, complete the expansion of graphite oxide in an instant, and obtain thin-layer graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com