Process for production of cross copolymers, cross copolymers obtained by the process, and use thereof

A technology of cross-copolymer and manufacturing method, applied in the field of specific cross-copolymer, can solve the problems of reduced transparency, loss of flexibility, opacity, etc., and achieve the effects of excellent compatibility, excellent flexibility and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

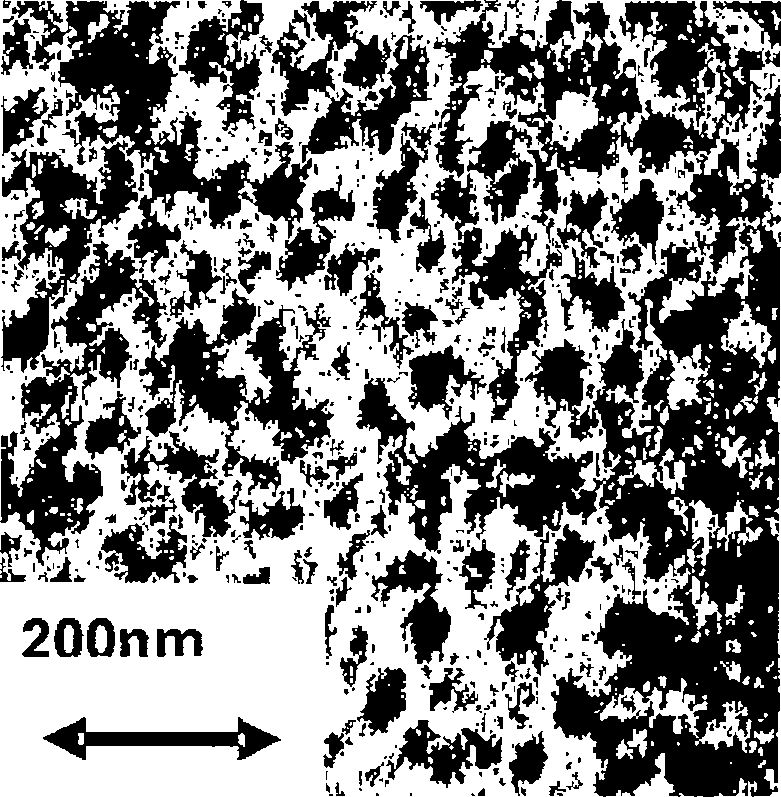

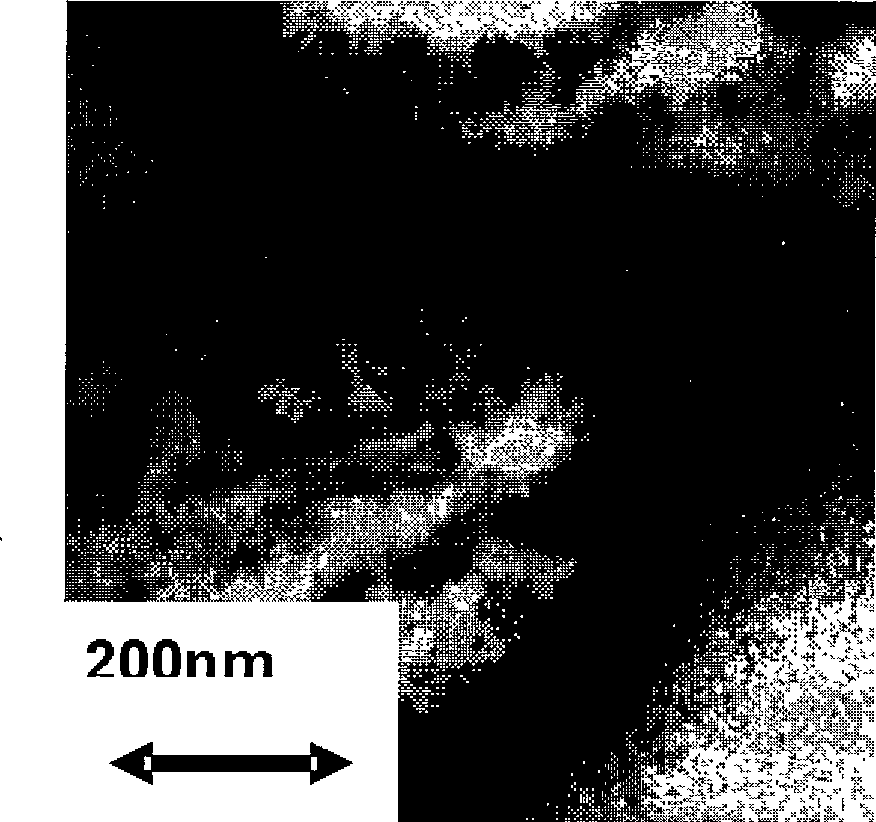

Image

Examples

Embodiment 12

[0222] In Example 12, as a catalyst (transition metal compound), rac-dimethylmethylene(4,5-benzo-1-indenyl)(1-indenyl)zirconium dichloride (Formula 8) was used .

[0223] Formula 8

Embodiment 1

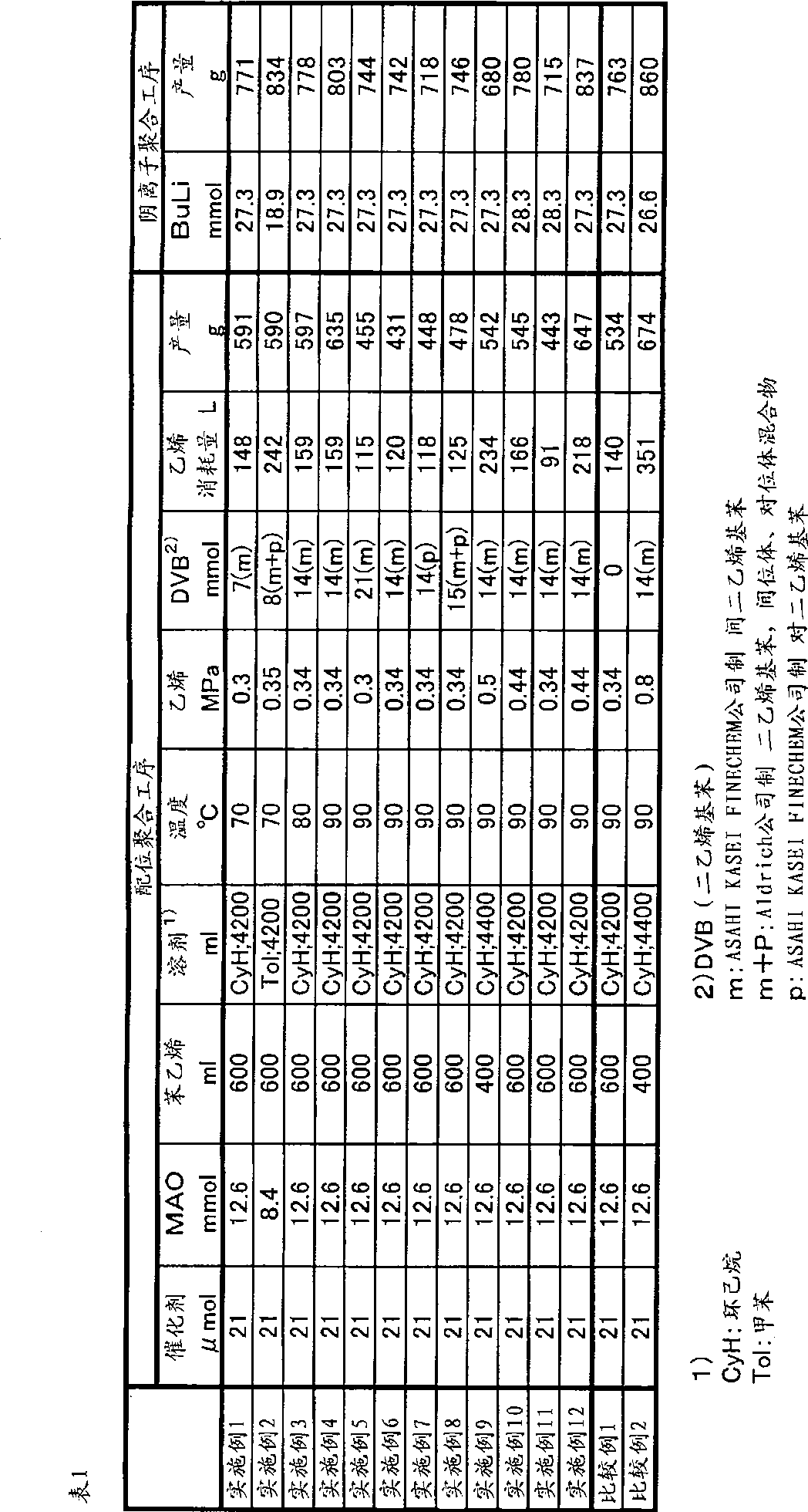

[0225]

[0226] As a catalyst, rac-dimethylmethylenebis(4,5-benzo-1-indenyl)zirconium dichloride was used and carried out as follows.

[0227] Polymerization was carried out using an autoclave having a capacity of 10 L and equipped with a stirrer and a jacket for heating and cooling.

[0228] 4200 ml of cyclohexane, 600 ml of styrene, and m-divinylbenzene (7 mmol as m-divinylbenzene) manufactured by ASAHI KASEI FINECHEM Co., Ltd. were charged, and heated and stirred at an internal temperature of 70°C. Bubble about 200L of dry nitrogen to remove moisture in the system and the polymerization liquid. Then, 8.4 mmol of triisobutylaluminum and 12.6 mmol of methylaluminoxane (manufactured by TOSOH AKZO, PMAO-3A) (manufactured by TOSOH AKZO Co., Ltd., PMAO-3A) (referred to as MAO in the table) were added based on Al, and ethylene was immediately introduced. MPa(2.0Kg / cm 2G) After stabilizing under the pressure, add rac-dimethylmethylene bis (4,5-benzo-1-indenyl) zirconium dichlor...

Embodiment 2

[0232] Polymerization was performed under the conditions described in Table 1 in the same procedure as in Example 1 using toluene as a solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com