Method for benzo (alpha) pyrene removal from red clover extract using ultramicro communication technique

An ultra-fine pulverization technology, a technology of red clover, is applied in the field of extraction and application of traditional Chinese medicine, and can solve the problems of low efficiency of benzo[a]pyrene and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

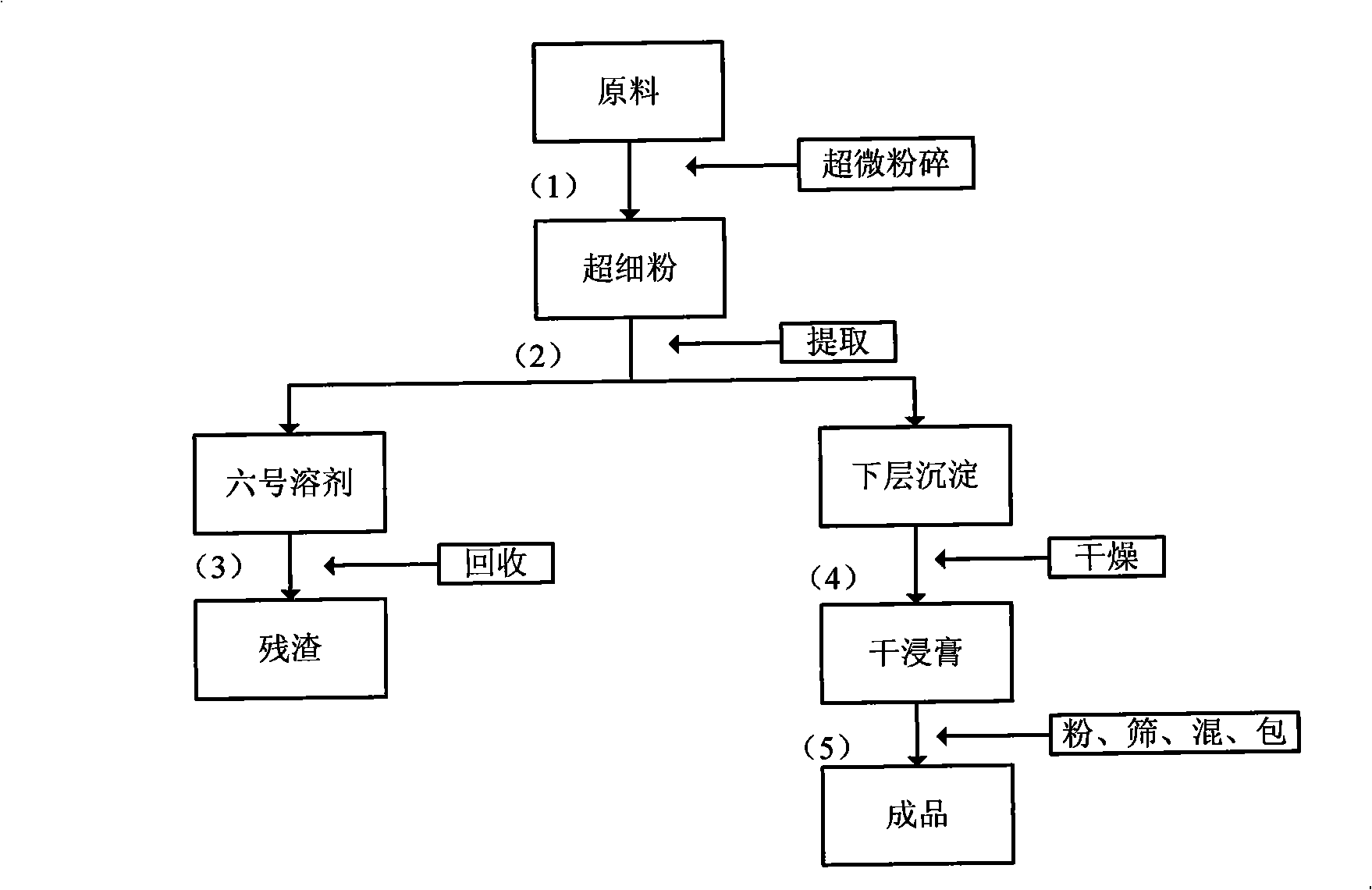

Image

Examples

Embodiment 1

[0032] 1. Superfine pulverization: Take the red clover extract, put it in a superfine pulverizer, pulverize it for 30 minutes, and the particle size should not exceed 75 μm, and set it aside.

[0033] 2. Extraction: Put 280kg of red clover extract into the 2T alcohol sinking tank, execute according to the "2T alcohol sinking tank standard operating procedure", stir and extract 4 times under reflux at 80-90°C, ethyl acetate and petroleum ether (boiling point 60~90 ℃) equal mass ratio solvent consumption is 6 times of the red clover extract ultrafine pulverized material quantity for the first time, and 5 times of the second to fourth times, extracting for 1 hour each time, cooling to At room temperature, stand still for the first to third times to separate the layers. The solvent layer is siphoned from the top of the tank. After the last stirring and cooling, it is released from the bottom cover, transferred to a stainless steel bucket, and allowed to stand for 2 hours to separat...

Embodiment 2

[0038] Effects of Different Grinding Methods on the Removal Efficiency of Trifolium Trifolium Benzo[a]pyrene

[0039] Experiment number

[0040] Adopt different pulverizing methods, all the other technological processes are identical with embodiment 1, and test result shows, the content of benzo[a]pyrene in the product after superfine pulverization of red clover extract is higher than that of benzo[a]pyrene in common production method product. The content of pyrene was significantly reduced, and the removal efficiency was doubled.

Embodiment 3

[0042] Effects of Different Grinding Particle Sizes on the Removal Efficiency of Trifolium Trifolium Benzo[a]pyrene

[0043] Experiment number

[0044] Adopt different pulverization time, all the other technological processes are identical with embodiment 1, and test result shows: the content of benzo[a]pyrene in the product after superfine pulverization of red clover extract reduces along with the reduction of pulverization particle diameter; When the pulverized particle size is below 75 μm, the removal efficiency of benzo[a]pyrene no longer increases, so the red clover extract is ultrafinely pulverized to a particle size of no more than 75 μm, and then passed through ethyl acetate and petroleum ether (boiling point 60-90 ℃) equal ratio solvent stirring heat reflux extraction, drying and other processes to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com