Reverse osmosis membrane on-line chemical cleaning method and cleaning agent

A reverse osmosis membrane and chemical cleaning technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of undisclosed formulas and expensive prices, and achieve simple and easy control of parameters, low prices, and obvious cleaning effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides an alkaline reverse osmosis membrane cleaning agent, comprising:

[0039] A solution of tetrasodium ethylenediaminetetraacetic acid (EDTA-4Na) or sodium dodecylbenzenesulfonate or sodium tripolyphosphate with a concentration of 1-4%, and a pH of 10-12.

[0040] Wherein, the reagent for adjusting the pH value of the alkaline reverse osmosis membrane cleaning agent between 10 and 12 is sodium hydroxide or potassium hydroxide.

[0041] Wherein, the optimal concentration of tetrasodium edetate, sodium dodecylbenzenesulfonate or sodium tripolyphosphate in the alkaline reverse osmosis membrane cleaning agent is 2-3%.

[0042] Wherein, the optimal pH range of the alkaline reverse osmosis membrane cleaning agent is 11-12.

[0043] The preparation method of the alkaline reverse osmosis membrane cleaning agent is a conventional method, and the present embodiment provides a kind of implementation mode, at first preparation concentration is at 1%~4%...

Embodiment 2

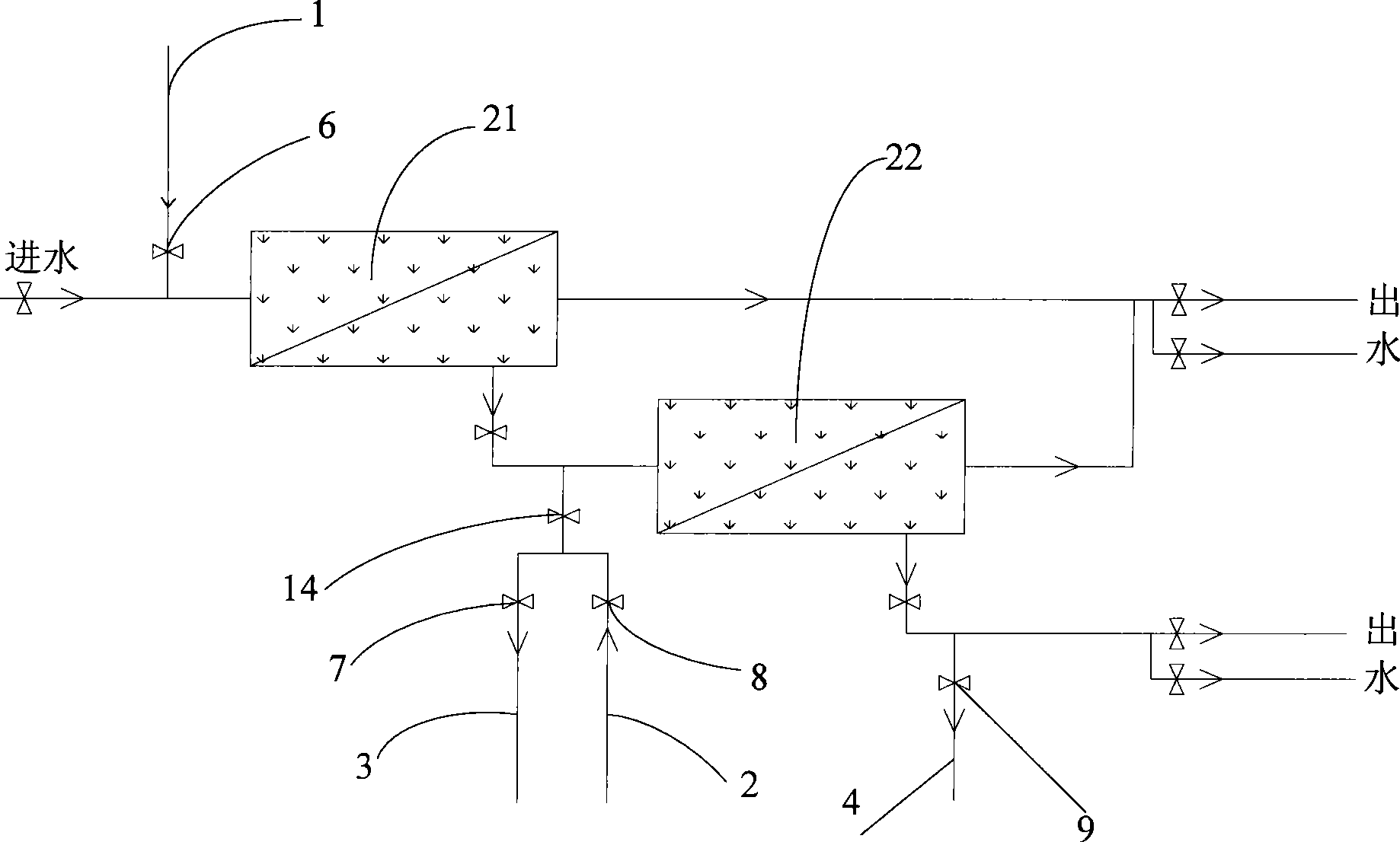

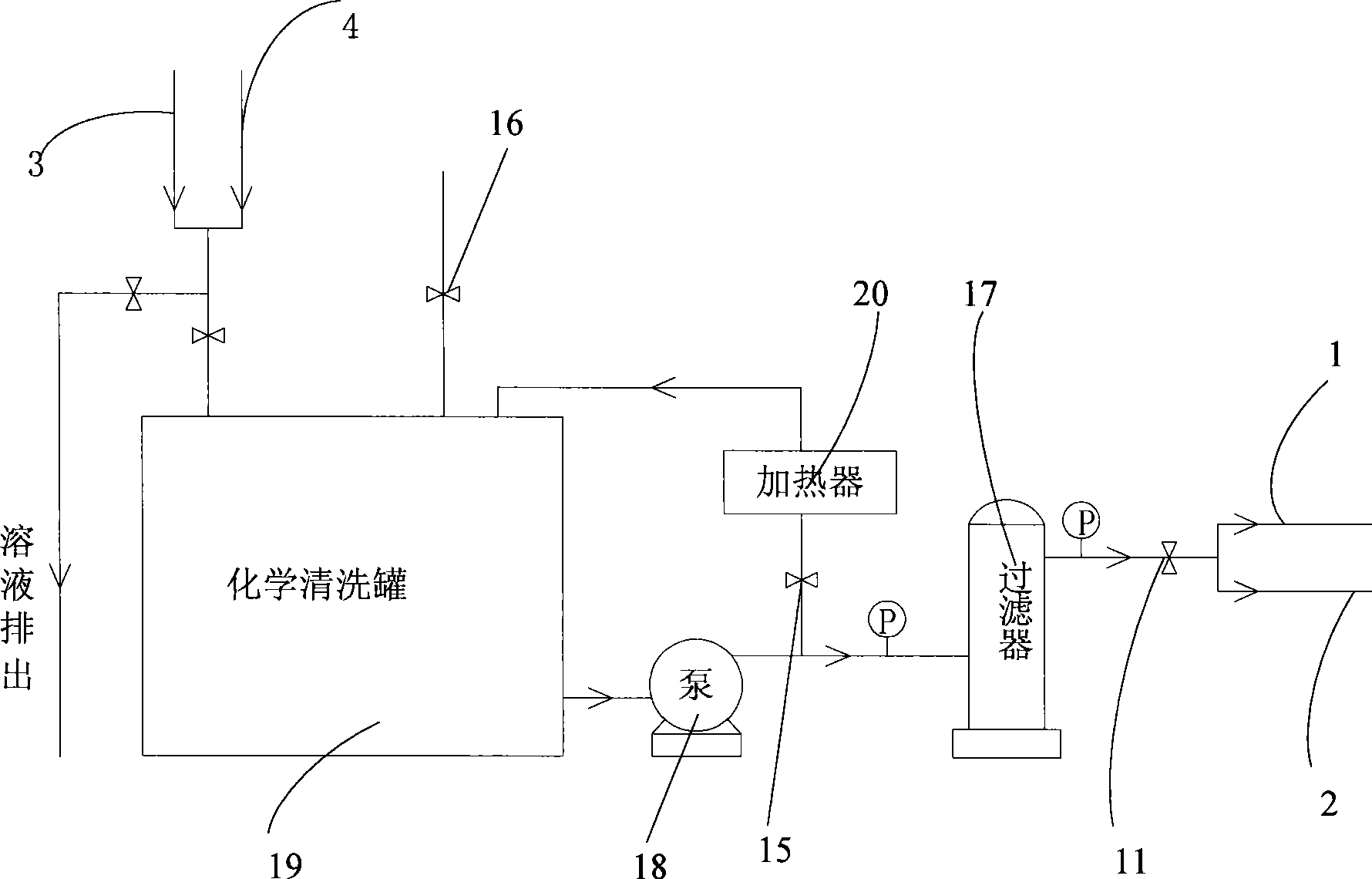

[0051] Attached below figure 1 , 2 3. Describe the specific method for online cleaning of the reverse osmosis membrane using the alkaline reverse osmosis membrane cleaning agent described in this embodiment.

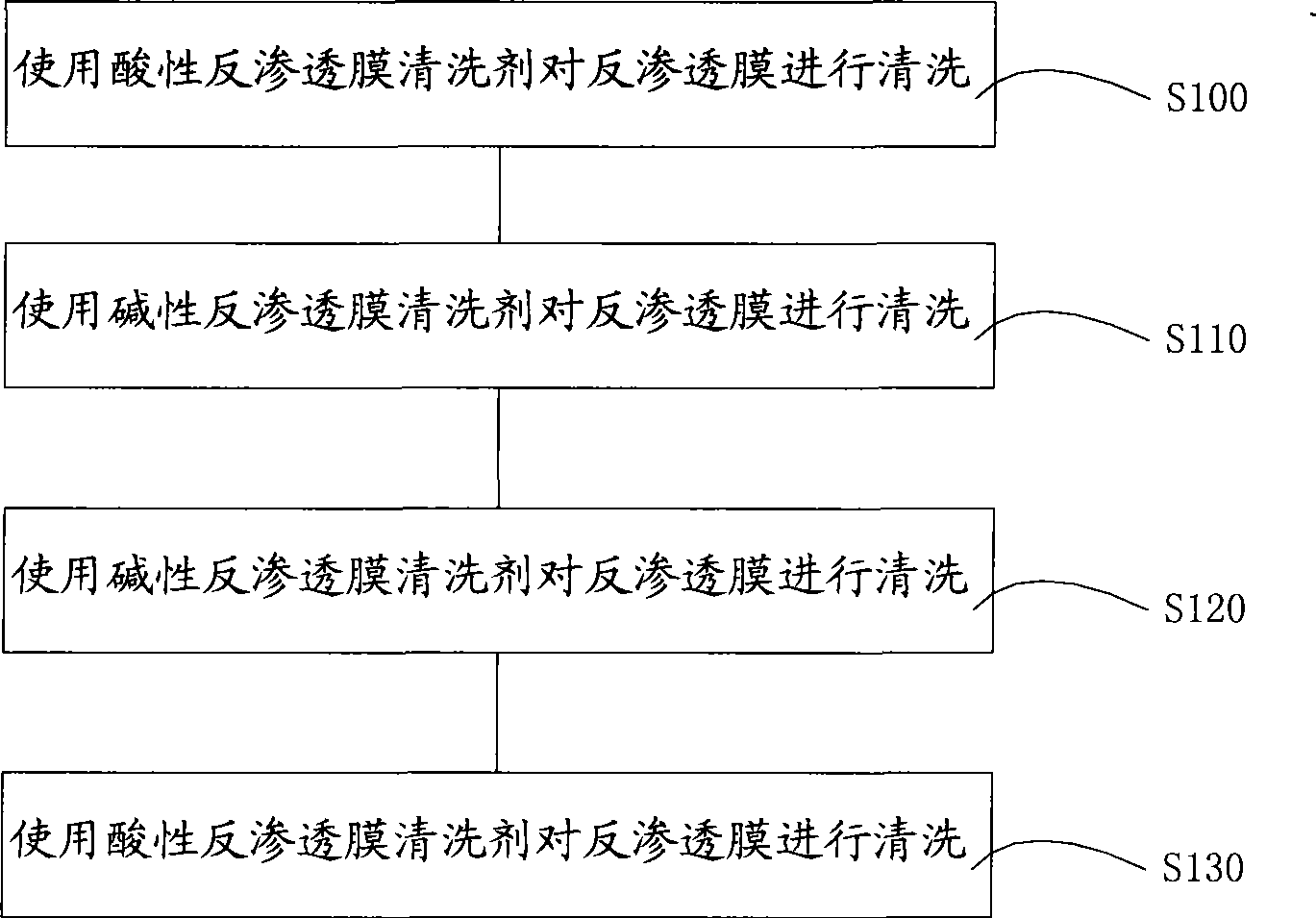

[0052] The method of using the alkaline reverse osmosis membrane cleaning agent described in this embodiment to carry out on-line chemical cleaning of the reverse osmosis membrane is: alternately use the acidic reverse osmosis membrane cleaning agent and the alkaline reverse osmosis membrane cleaning agent to clean the reverse osmosis membrane.

[0053] Described acidic reverse osmosis membrane cleaning agent comprises: concentration is 1~4% citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) or oxalic acid or phosphoric acid solution, the pH of the solution is 1-4.

[0054] The preparation method of the acidic reverse osmosis membrane cleaning agent is a conventional method, and this embodiment provides an implementation mode, first preparing a monohydrate citric acid or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com