Method for recovering metallic oxide from waste aluminum base V-Mo-Ni catalyst

A technology of catalysts and oxides, which is applied in the direction of improving process efficiency, etc., can solve the problems of less comprehensive recycling, difficulty in realizing industrialization, and high cost of solvent recovery, and achieve good economic benefits, improve environmental conditions, and reduce recycling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

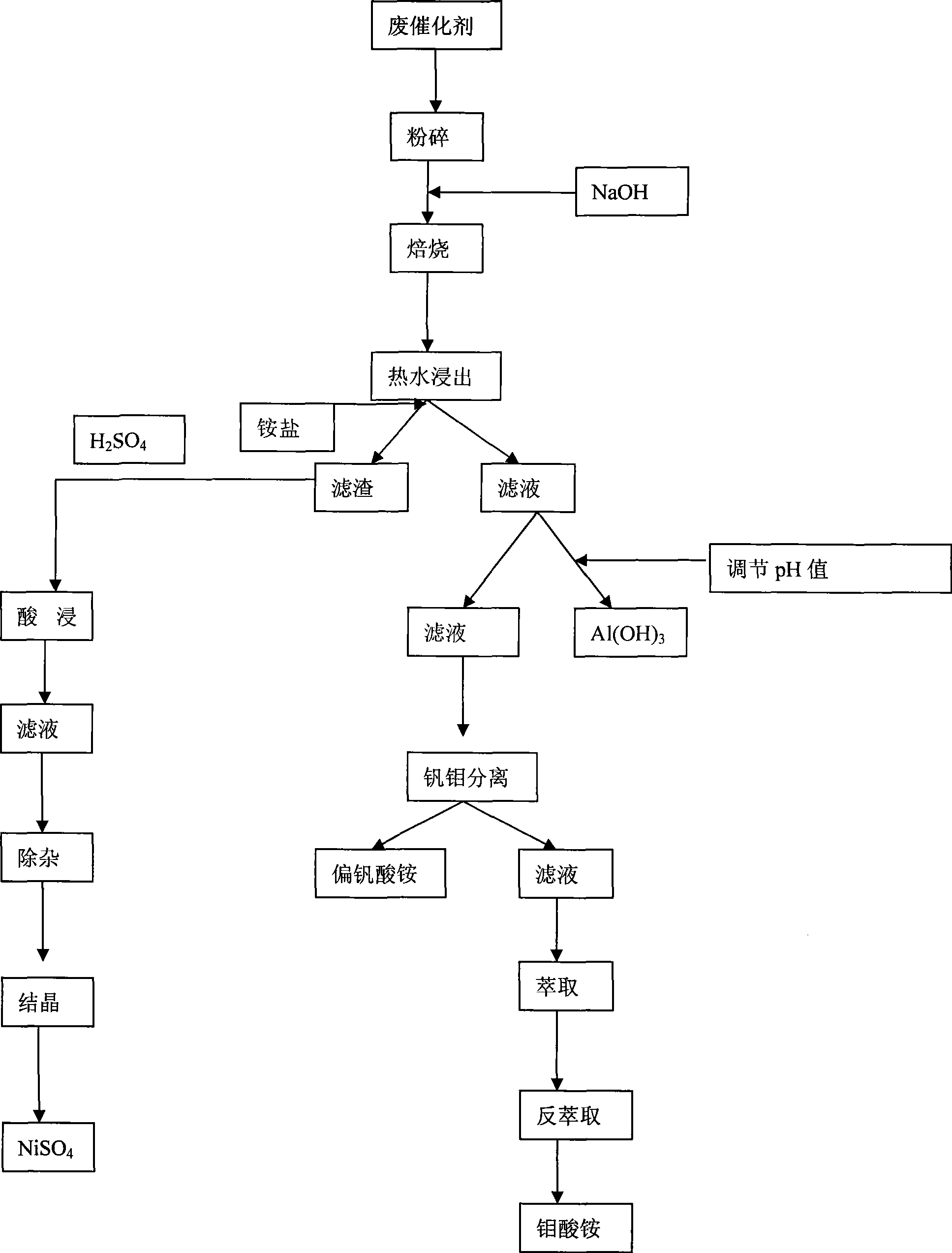

[0037] figure 1 It is a process flow diagram of the present invention.

[0038] 1) The waste aluminum-based vanadium-molybdenum-nickel catalyst after pulverization is fully mixed with a certain amount of sodium hydroxide, and sodium hydroxide and waste aluminum-based vanadium-molybdenum-nickel catalyst (according to Al 2 o 3 The molar ratio of ) is 2.6:1;

[0039] 2) Carry out high-temperature roasting with the mixed material in the rotary kiln, the temperature is 700 ℃, constant temperature 6 hours, the conversion rate of vanadium, molybdenum is respectively 96.3%, 97.1%, the conversion rate of aluminum is 97.5%; The main reflection equation is as follows:

[0040] Al 2 o 3 +2NaOH=2NaAlO 2 +H 2 o

[0041] V 2 o 5 +6NaOH=2Na 3 VO 4 +3H 2 o

[0042] MoO3+2NaOH=Na 2 MoO 4 +H 2 O.

[0043] 3) After the sintered block is pulverized, it is washed with hot water at 80°C in countercurrent, the liquid-solid weight ratio is 5:1, and the time is 3 hours; sodium aluminat...

Embodiment 2

[0057] 1) The waste aluminum-based vanadium-molybdenum-nickel catalyst is fully mixed with sodium hydroxide, and the waste aluminum-based vanadium-molybdenum-nickel catalyst is mixed with sodium hydroxide (according to Al 2 o 3 ) The molar ratio is 3.4:1.

[0058] 2) The mixed materials are roasted at high temperature in a rotary kiln at a temperature of 1000° C. and kept at a constant temperature for 4.5 hours. The conversion rates of vanadium and molybdenum are 96.8% and 97.3% respectively, and the conversion rates of aluminum are 98.5%;

[0059] 3) After the sintered block is pulverized, it is washed with hot water countercurrently. The water consumption is 7.5:1 by weight ratio of liquid to solid. The temperature is 90°C for 2.5 hours.

[0060] 4) Separation by filtration and precipitation to obtain Al(OH) 3 Same as Example 1, the purity reaches more than 99.2%.

[0061] 5) Filter Al(OH) 3 The precipitated filtrate is adjusted to a pH value of 6.9, and an ammonium salt...

Embodiment 3

[0065] 1) The waste aluminum-based vanadium-molybdenum-nickel catalyst is fully mixed with sodium hydroxide, and the waste aluminum-based vanadium-molybdenum-nickel catalyst is mixed with sodium hydroxide (according to Al 2 o 3 ) The molar ratio is 4:1.

[0066] 2) The mixed waste aluminum-based vanadium-molybdenum-nickel catalyst and sodium hydroxide are roasted at a high temperature at a temperature of 1200° C. and a constant temperature of 3 hours. The conversion rates of vanadium and molybdenum are 97.6% and 98.7% respectively, and the conversion rate of aluminum is 99.5%. %.

[0067] 3) After the sintered block is pulverized, it is washed with hot water countercurrently. The amount of water is 10:1, the temperature is 100°C, and the time is 0.5 hours.

[0068] 4) Filtrate and separate the water immersion solution, and precipitate to obtain Al(OH) 3 Embodiment 1 is the same.

[0069] 5) Filter Al(OH) 3 The filtrate after precipitation is adjusted to a pH value of 7.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com