Phase-controlled constant pressure type ultra-high pressure water supercharger

A water booster, ultra-high pressure technology, applied in fluid pressure converters, non-mechanical abrasive jet generation equipment, explosion generation devices, etc., can solve the problem of poor high temperature resistance, poor machining performance, and heavy weight problems, to achieve the effect of high machining performance, light weight, and perfect safety sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

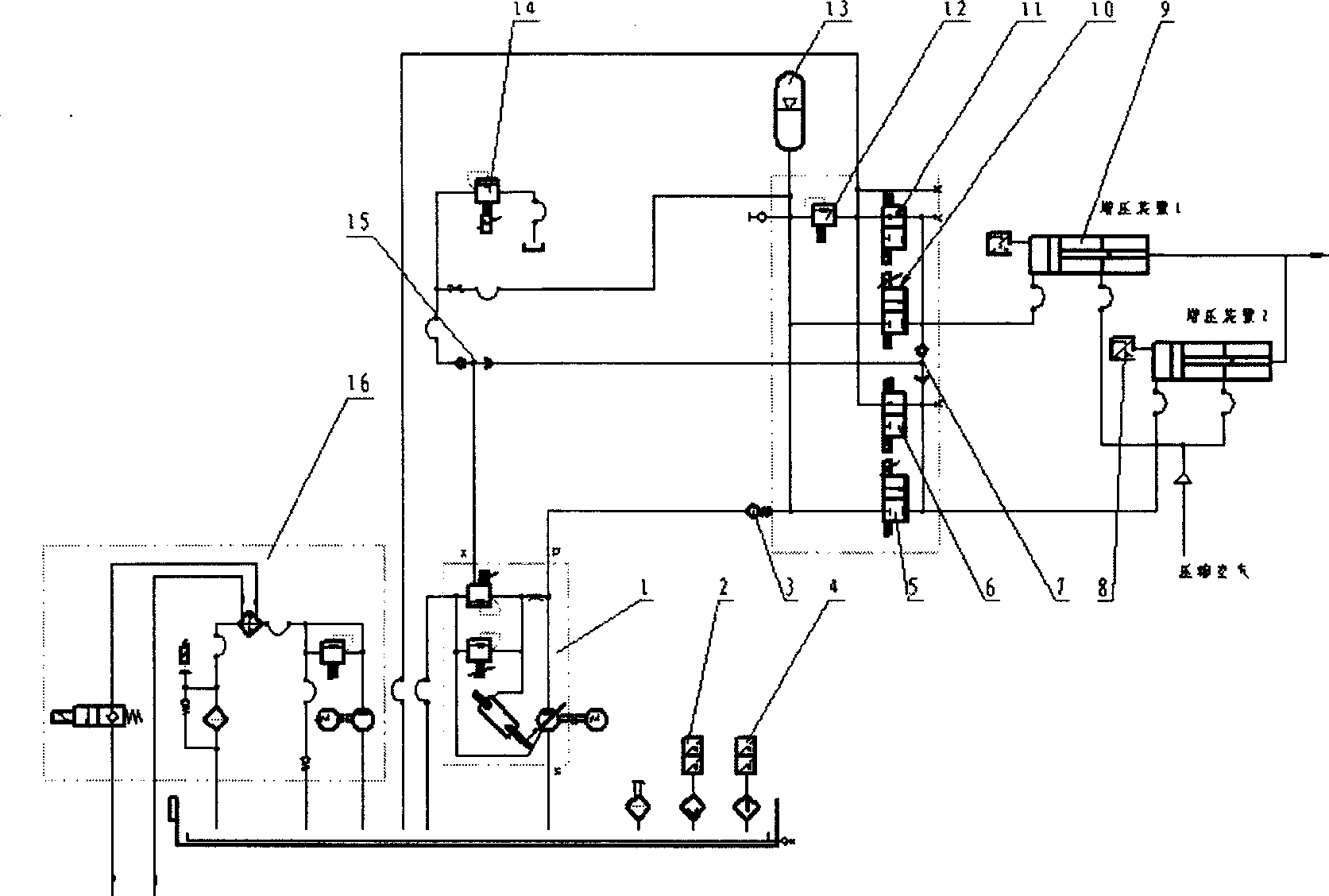

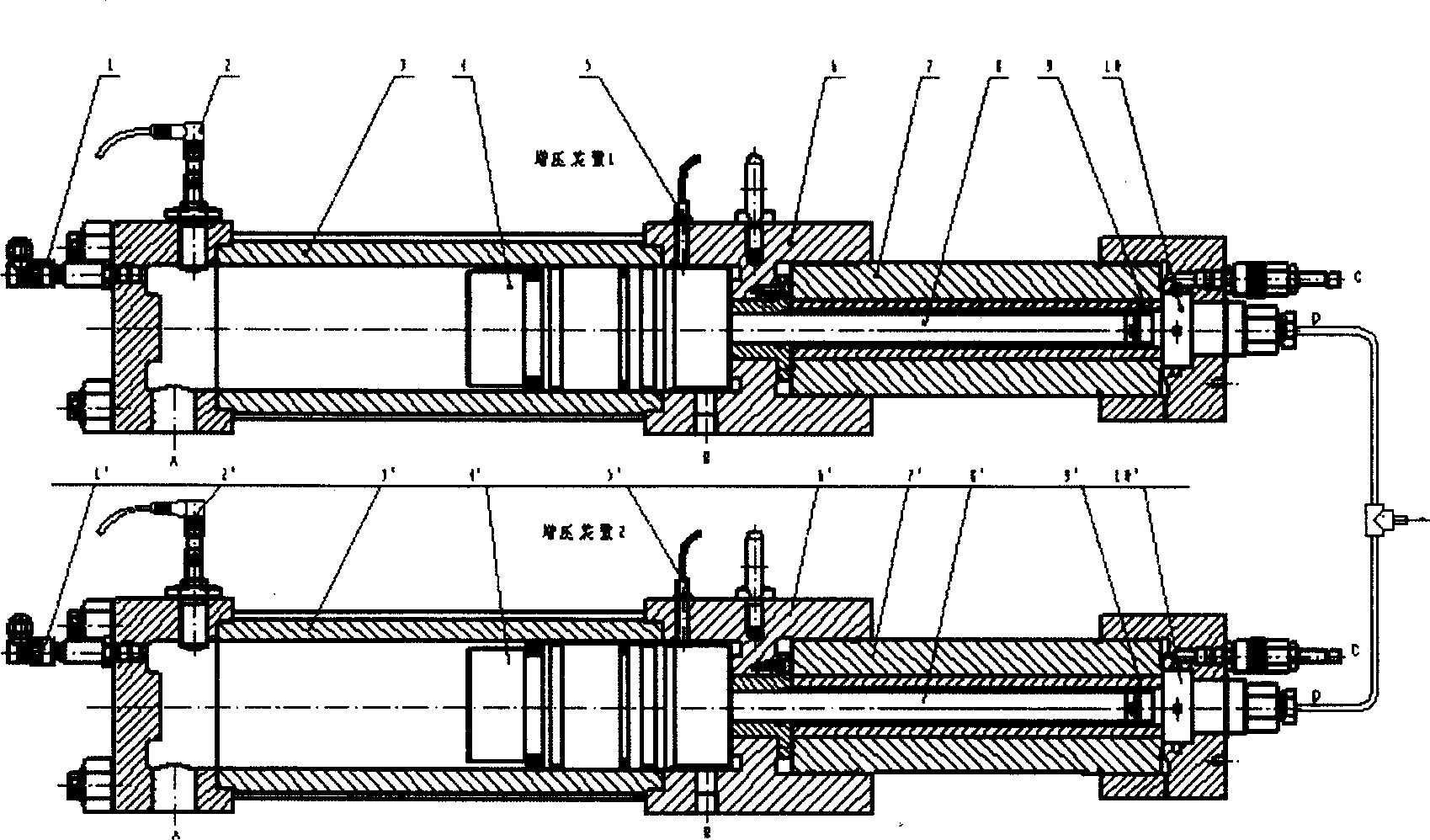

[0020] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Depend on figure 1 It can be seen that the present invention includes completely independent double boosting devices (boosting device 1 and boosting device 2), completely independent oil circuit system (comprising oil inlet proportional valves (5, 10) and oil return relief valves (6, 11)) and their independent sensing and control circuits, the main features of which are: the system hydraulic pressure is generated by a variable plunger hydraulic pump (1) with pressure and load compensation; figure 2 It can be seen that the system pressure is sent to the two hydraulic cylinders (3, 3') of the corresponding booster device through the independent proportional valves, the corresponding pressure sensors (1, 1'), the proportional valve amplifier board (or PLC ) and the proportional valve form an independent closed-loop control of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com