Induction and electrical arc composite heat source stud welding method

A composite heat source, induction heating power source technology, applied in arc welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of lack of fusion, production efficiency impact, efficiency impact, etc., to achieve convenient preheating, welding quality improvement, and efficiency improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

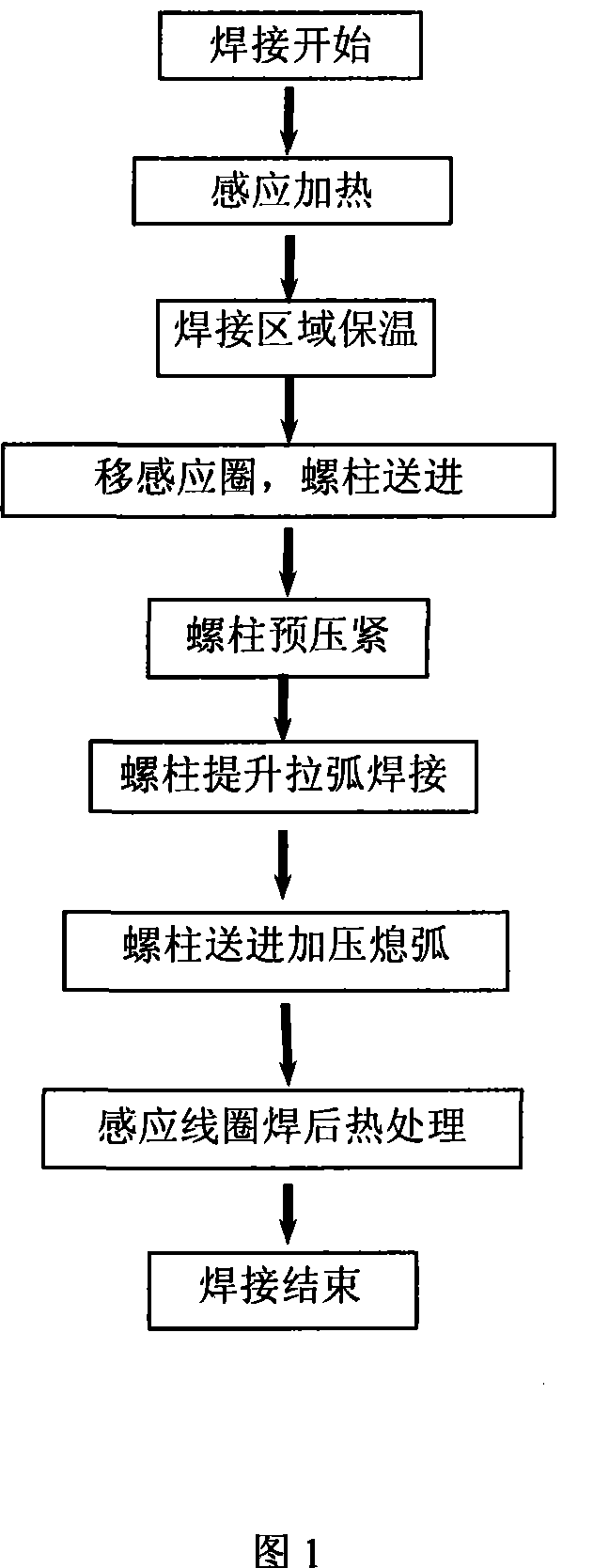

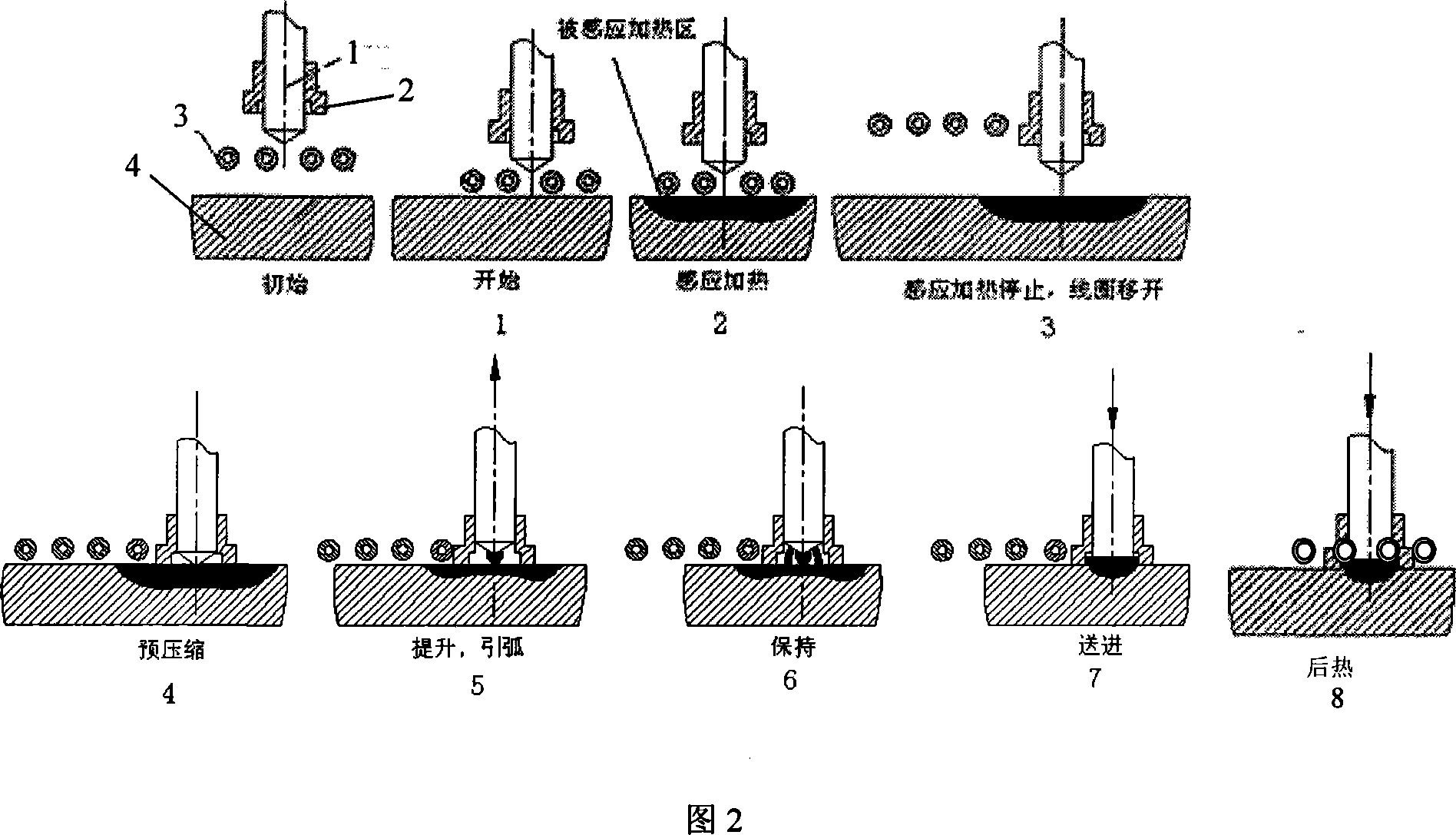

[0022] Example, combined with figure 1 with figure 2 , take stud welding with a diameter of 22mm and a steel plate with a thickness of 20mm as an example. A steel stud with a diameter of 20mm and a length of 60mm is pre-clamped on the stud welding torch, and a ceramic ring 2 is clamped at the front end of the stud. At this time, the stud welding torch and the induction coil 3 should both be in the lifting state. Start the start button of the control system, the induction coil 3 drops to a distance of 3mm, the induction heating power supply heats the welding area of the workpiece 4 through the induction coil 3, the heating time is controlled by the system to 10s, the heating power is 600, and the surface heating temperature of the workpiece 4 is 200 ℃-300℃, after heating, the induction coil 3 is raised, and then the stud welding torch is lowered until the stud and the ceramic ring 2 and the workpiece 4 are kept pre-compressed, the control system sends a welding signal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com