Optical resin composition having excellent impact resistance and method for fabricating optical lens using the same

A resin composition and spectacle lens technology, applied in glasses/goggles, coatings, instruments, etc., can solve the problems of high thermal expansion coefficient, loss of optical lens, failure to pass the production of spectacle lens specifications for safety, etc., and achieve low thermal expansion coefficient , Good effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

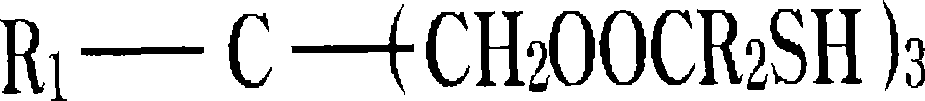

Method used

Image

Examples

Embodiment 1

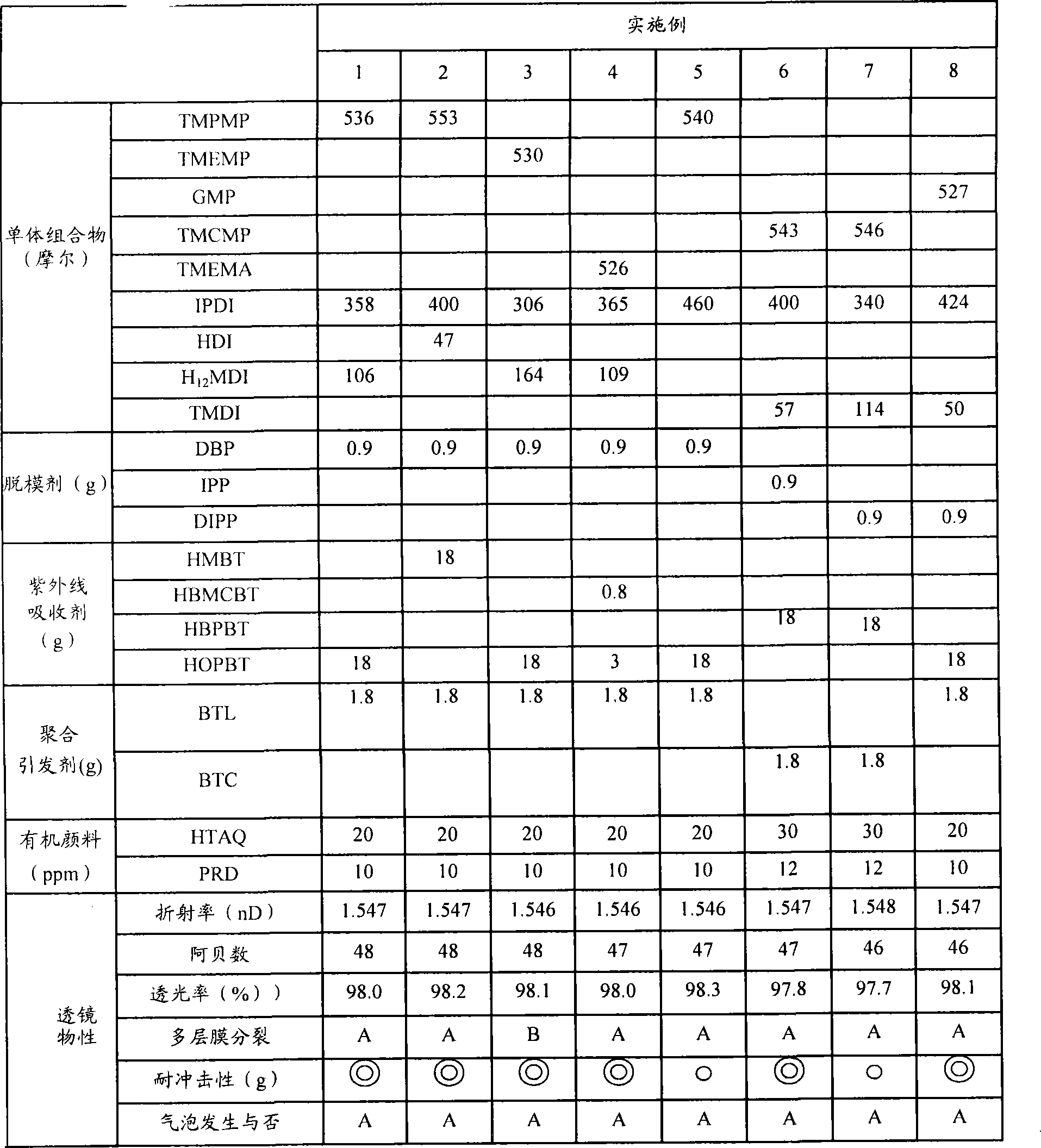

[0035] The optical material of the present invention and the preparation method of lens are as follows: trimethylolpropane tris (mercapto propionate) 536g, mix isophorone diisocyanate (IPDI) 358g, 4,4'-methylene bis (cyclohexyl) Diisocyanate) 106g After preparing the monomer composition, 2-(2'-hydroxy-5'-tert-octylphenyl)-2H-benzotriazole (2-(2'-hydroxy- 5′-t-octylphenyl)-2H-benzotriazole) 18g, 0.9g of dibutyl phthalate as a release agent, 1-hydroxyl-4-(p-methylaniline) anthraquinone (1- Hydroxy-4-(p-toluidine)anthraquinone) (blue) 20ppm, alizarone dyes (red) 10ppm, and dibutyltin dilaurate as a polymerization initiator 1.8g were put into a mixing tank equipped with a stirrer, After replacing with nitrogen and removing the air in the mixing barrel, stir under reduced pressure for 2 hours, stop stirring, degas under reduced pressure, and pour into a glass mold fixed with polyester tape (diopter -5.00).

[0036](2) Put the glass mold injected with the mixture into a steel circu...

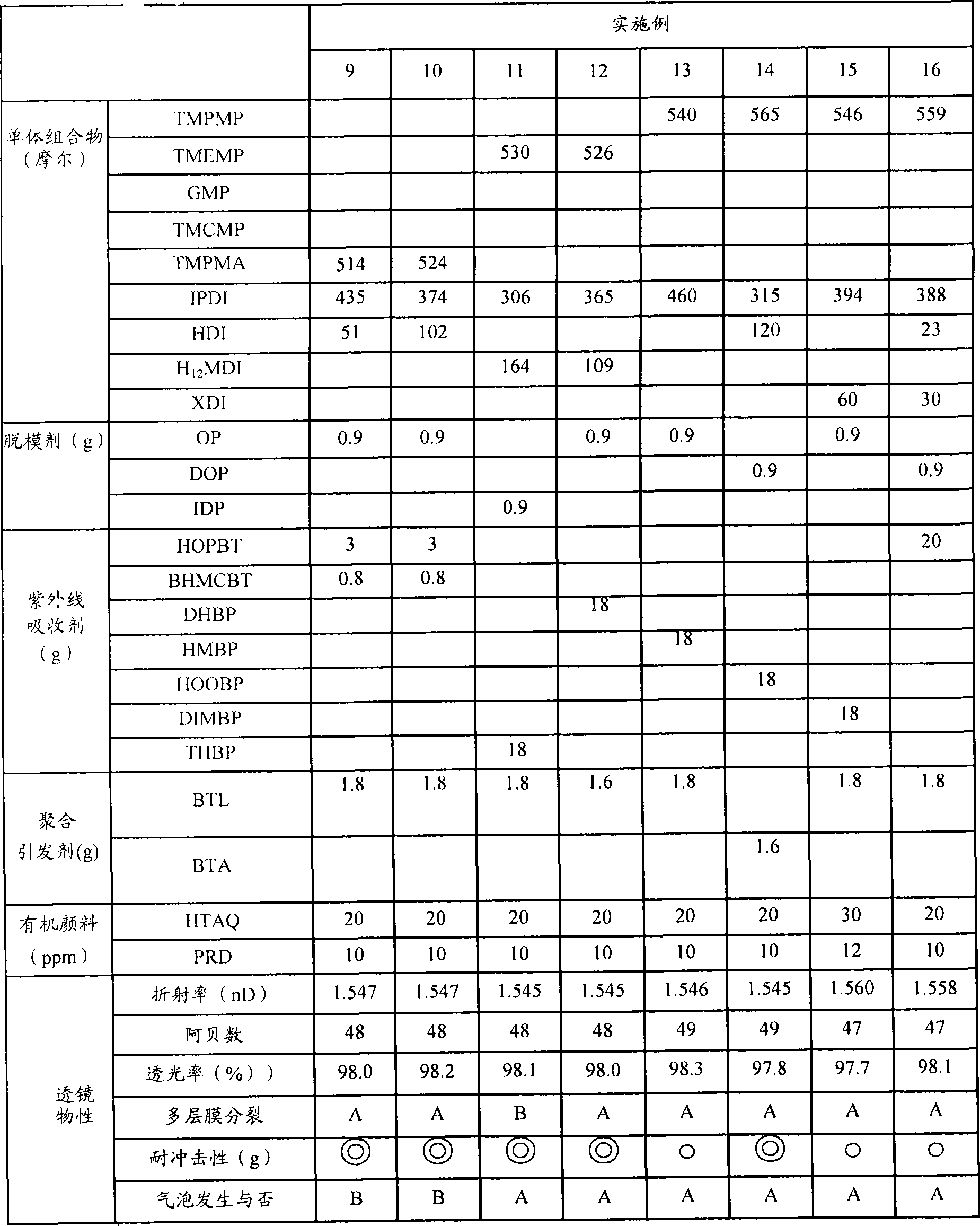

Embodiment 2~16

[0047] According to the same method as in Example 1, compositions and lenses were prepared in the combinations described in Tables 1 and 2, respectively, and the results were recorded in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com