Method for preparing graphical substrate of GaN-based LED by silicon 001 crystal face

A graphics substrate and graphics technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost and poor quality, and achieve the effect of low cost, good quality and improved crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

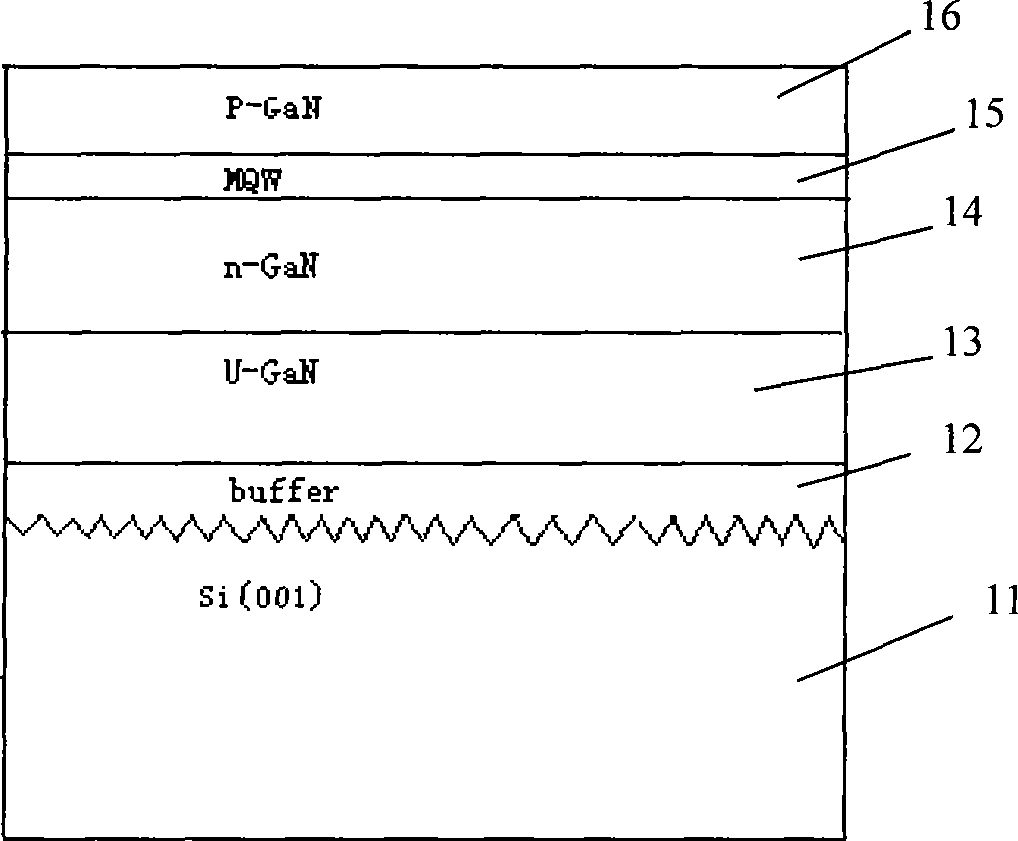

[0027] The method for preparing the pattern substrate of GaN-based LED by using silicon (001) of the present invention is used to prepare a silicon wafer substrate with Si(111) surface, and then the GaN-based LED structure is epitaxially grown on the silicon wafer substrate by the MOCVD method The LED structure includes a buffer layer 12, a u-GaN layer 13, an n-GaN layer 14, a light-emitting layer 15, and a p-GaN layer 16, which are sequentially grown on the substrate 11, such as figure 1 Shown.

[0028] This method first prepares a mask with patterned openings on Si (001): firstly, SiO is deposited on the silicon (001) by PECVD (plasma enhanced chemical vapor deposition). 2 For the mask layer, the evaporation temperature is 100-400°C and the thickness is 30-500nm. In this embodiment, the evaporation temperature is 200°C, the thickness is 70nm, and the evaporation time is 4 minutes; then, the photolithography technique is used to peel off the part SiO 2 Mask, in SiO 2 The pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com