Method for activating magnesium doping gallium nitride base material and LED P-type gallium nitride

A gallium nitride-based, nitrogen-based technology, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of GaN damage and failure, and achieve the effect of reducing negative effects and improving doping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

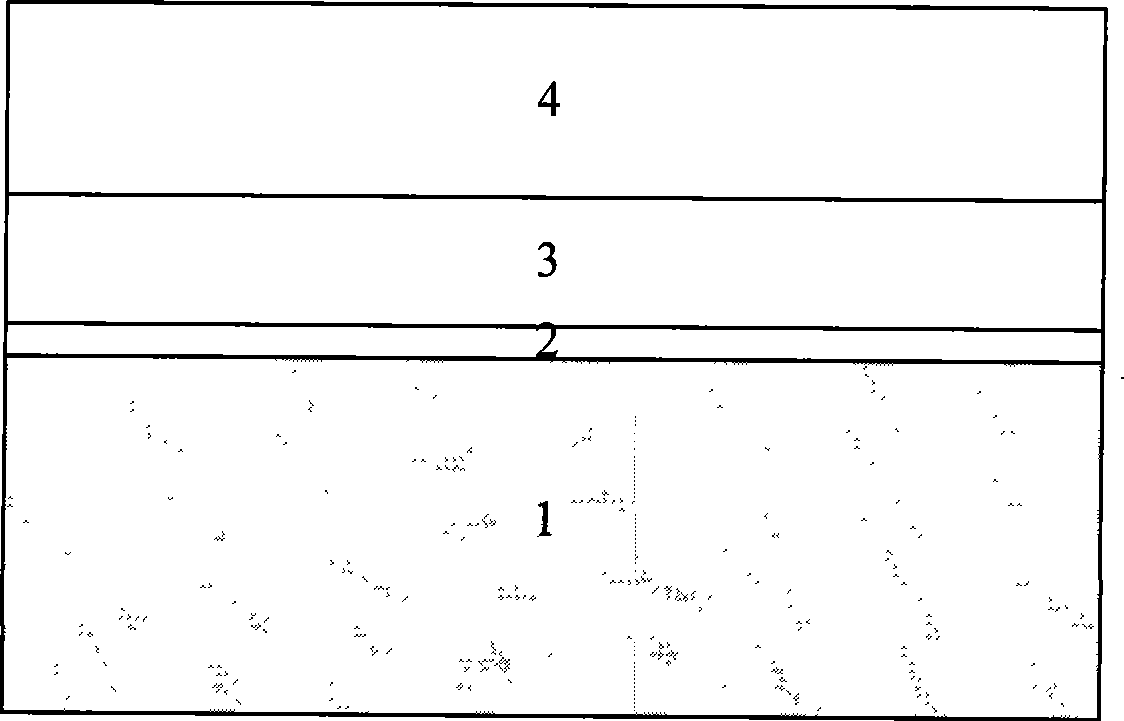

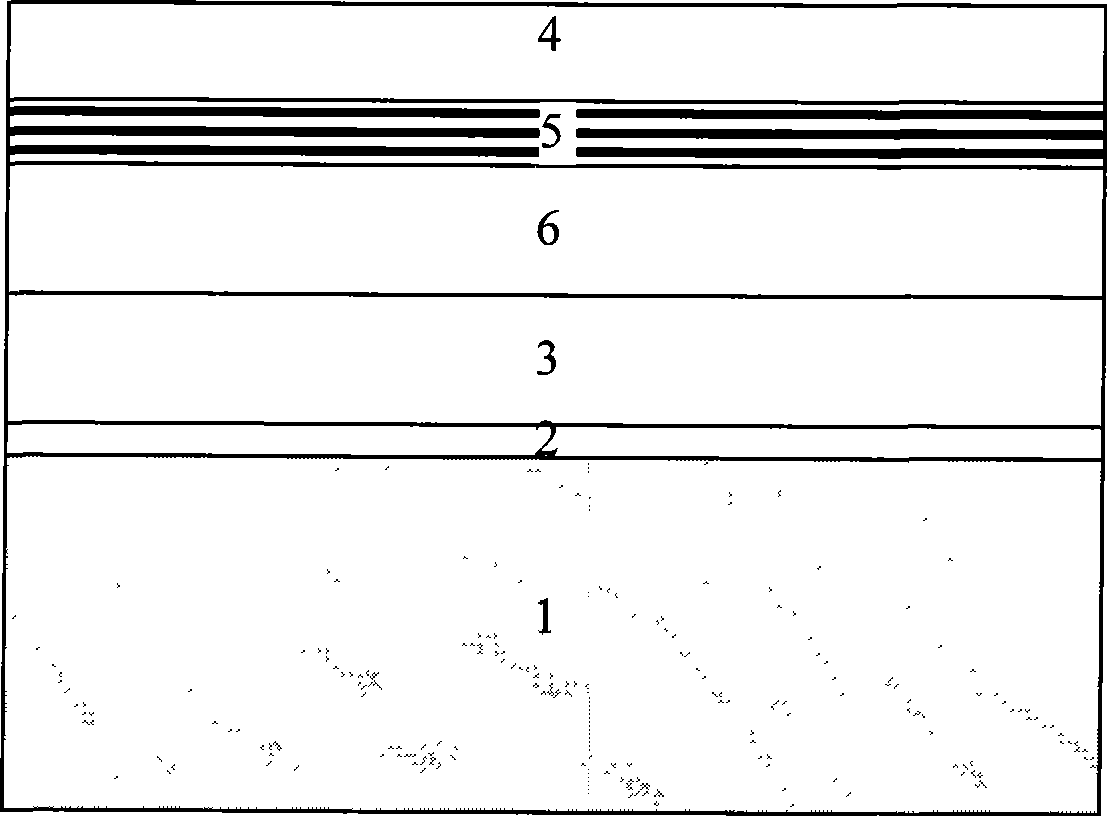

[0029] Such as figure 1 As shown, the single-layer Mg-doped GaN-based materials are from bottom to top: sapphire substrate 1, buffer layer 2, non-doped GaN (thickness more than 1 micron) 3, GaN:Mg (thickness greater than 300 nanometers) 4 .

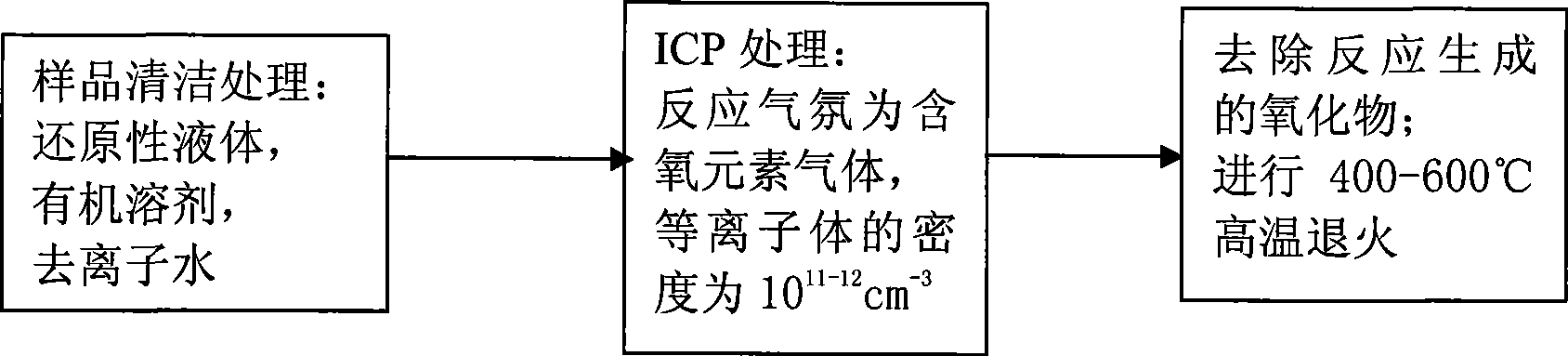

[0030] refer to figure 2 , the above-mentioned Mg-doped GaN-based material is specifically processed as follows:

[0031] 1) Cleaning treatment of Mg-doped GaN-based material samples. First, the oxide layer and contamination on the surface of the sapphire substrate 1 and GaN:Mg4 are removed with a reducing liquid, and then the surface oil is further removed with an organic solvent, and then the GaN-based material sample is washed with deionized water.

[0032] 2) ICP processing. The reaction atmosphere is oxygen, the source power of the ICP can be adjusted between 100-500W, the bias power is 50-200W, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com