Process for extracting tea polyphenol in tea

An extraction process and a technology for tea polyphenols, which are applied in the field of extraction process of tea polyphenols in tea leaves, can solve the problems of easily causing pollution, high production cost, expensive column packing materials, etc., and achieve automation, easy automation, and easy removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

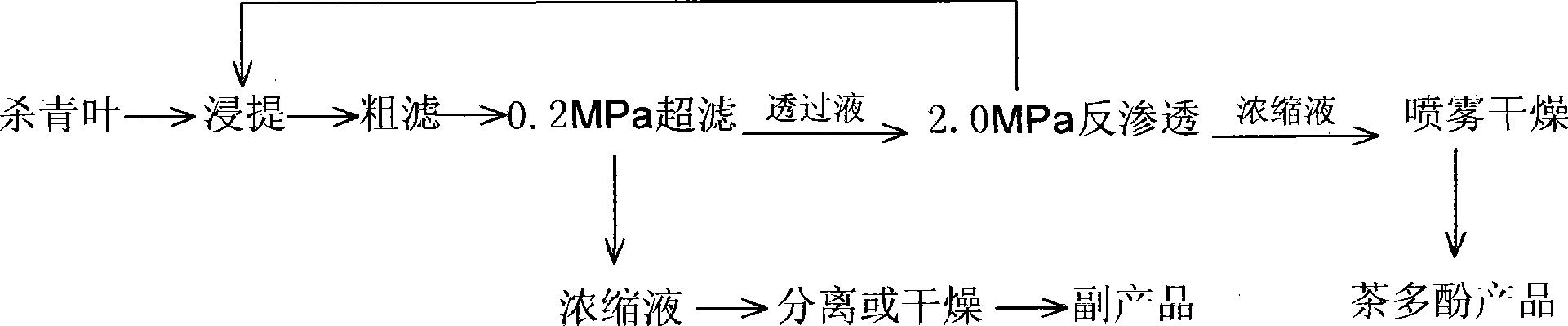

[0027] refer to figure 1 , a process for extracting tea polyphenols in tea leaves, comprising the steps of:

[0028] (1) steaming fresh tea leaves to obtain green leaves;

[0029] (2) extracting and filtering the green leaves, separating the filtrate through a reverse osmosis membrane to obtain a concentrated solution, and spray-drying the concentrated solution to obtain a tea polyphenol product.

[0030] In the step (1), the steam temperature of the steam fixation is 100-200° C., and the time is 30 seconds.

[0031] Filtration in step (2) includes performing coarse filtration first, followed by ultrafiltration, the ultrafiltration permeate is subjected to reverse osmosis membrane separation, and the ultrafiltration concentrate is separated or dried to obtain by-products.

[0032] The ultrafiltration press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com