Method for preparing organic semiconductor material rubrene micro-nano wire

An organic semiconductor and rubrene technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, metal material coating processes, etc., can solve the problems of complex preparation process and difficulty in precise control of finished product size, and achieves a simplified preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention designs a novel method for preparing rubrene micro-nanowires, an organic semiconductor material. Compared with previous methods, its outstanding feature is that rubrene is used as a raw material in a clean silicon wafer or a physical vapor transport method. The grown naphthacene single crystal substrate is prepared by vacuum evaporation, and under the conditions of controlling the deposition rate and evaporation time, it is deposited on the semiconductor substrate to form rubrene micro-nano Wire. Necessarily, during the vacuum evaporation process, the semiconductor substrate needs to be kept at room temperature, and the deposition rate (thickness-to-time ratio) of the evaporation raw material rubrene needs to be controlled at 0.1 nm / minute to 0.4 nm / minute.

[0025] The specific steps for the controllable preparation of the organic semiconductor material rubrene micro-nanowire are:

[0026] I. Use clean commercial silicon wafers or naphthacene sin...

Embodiment 1

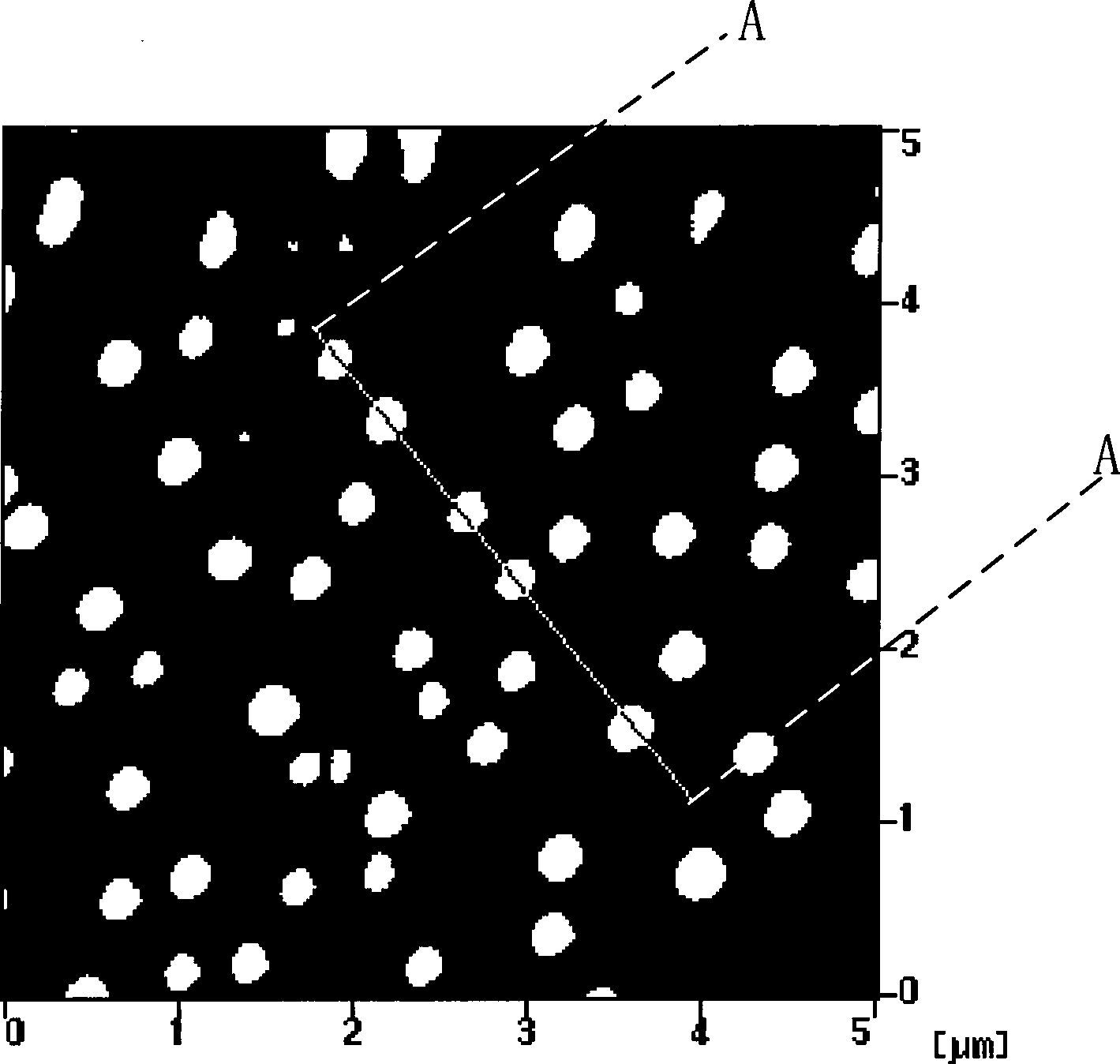

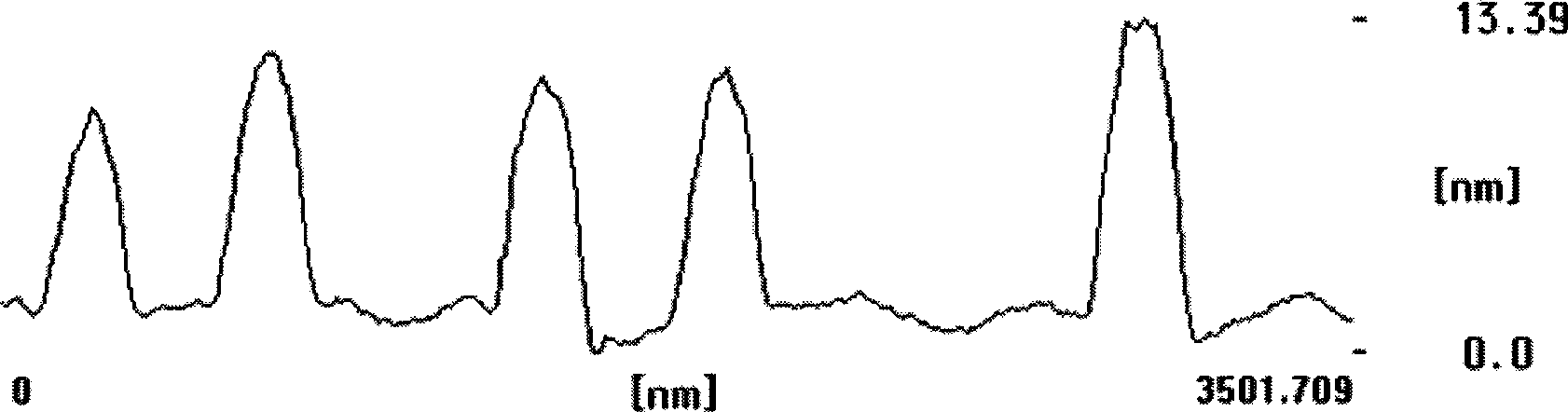

[0030] A physical vapor transport method is used to grow a millimeter-sized naphthacene single crystal under the background of an inert atmosphere at normal pressure. In a common high vacuum evaporation device, adjust the vacuum degree to 10 -3 Pa, using rubrene powder as the raw material, naphthacene single crystal as the substrate, and controlling the evaporation time to 4 minutes under the evaporation rate of 0.1nm / min. The surface of the film was tested by atomic force microscopy, and the morphology of rubrene micro-nanowires was determined by Figure 1a and Figure 1b It can be seen that the rubrene micro-nano wire is in the shape of a cone, with a diameter of about 300 nm at the bottom and a height of about 10 nm.

Embodiment 2

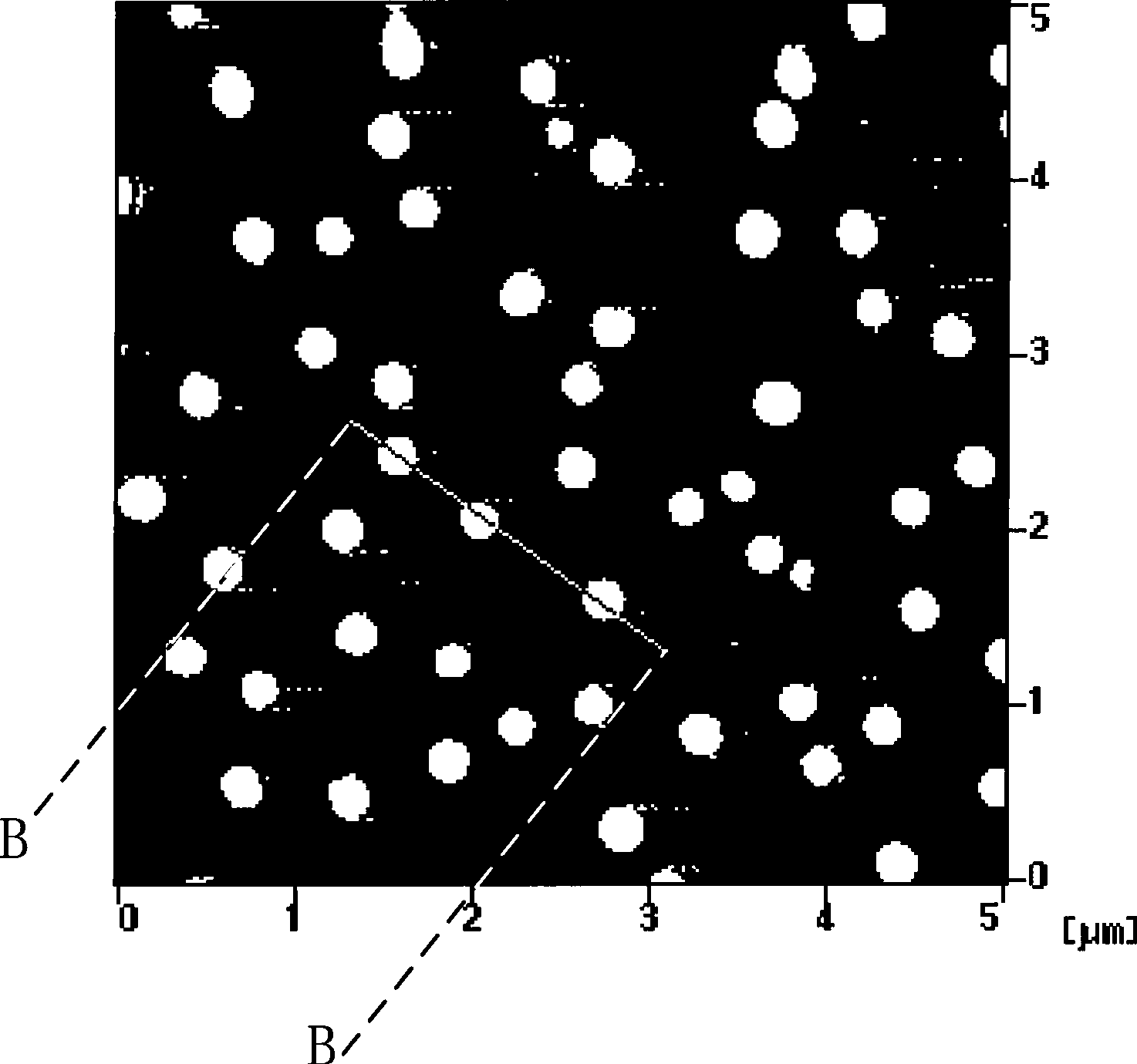

[0032] A physical vapor transport method is used to grow a millimeter-sized naphthacene single crystal under the background of an inert atmosphere at normal pressure. In a common high vacuum evaporation device, adjust the vacuum degree to 10 -3 Pa, using rubrene powder as the raw material, naphthacene single crystal as the substrate, and controlling the evaporation time to 8 minutes under the evaporation rate of 0.2nm / min. The surface of the film was tested by atomic force microscopy, and the morphology of rubrene micro-nanowires was determined by Figure 2a and Figure 2b It can be seen that the rubrene micro-nanowire is in the shape of a cone with a diameter of about 300 nm at the bottom and a height of about 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com