Preparation of metallic surface super-hydrophobic organic nano film

A metal surface and nano-film technology, applied in chemical instruments and methods, electrolytic organic material coatings, paints containing biocide, etc., can solve problems such as difficulties in industrial application and promotion, long cycle time, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

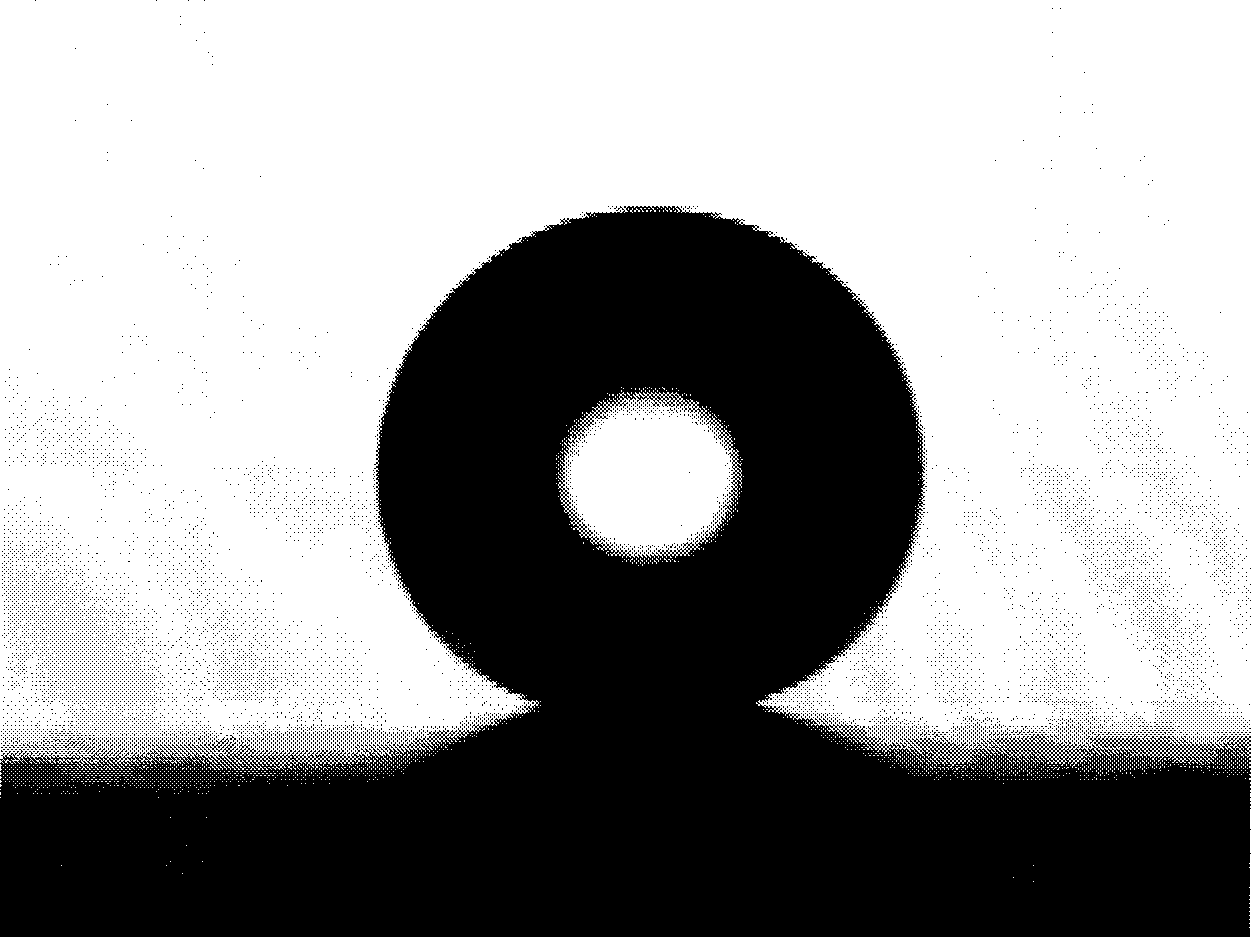

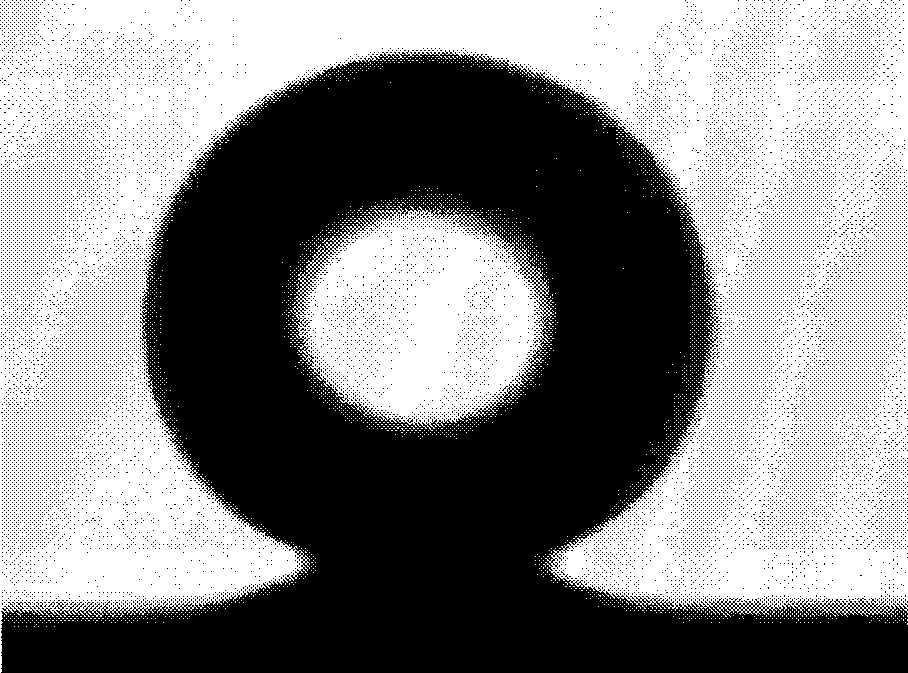

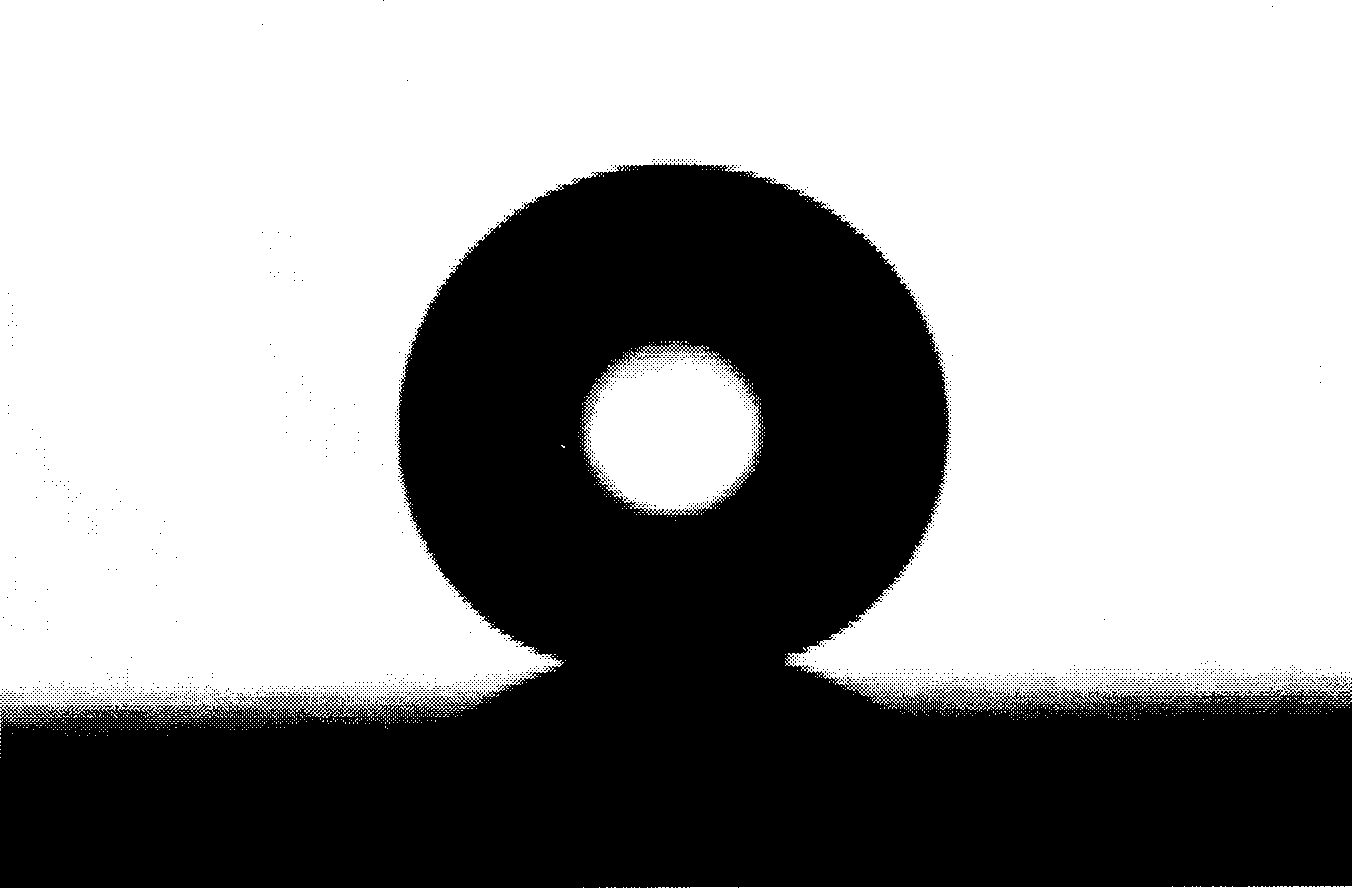

Image

Examples

Embodiment 1

[0069] In this embodiment, the substrate metal is a magnesium alloy with a grade of AZ31, and the size is 50×30×1.5 (mm). The specific steps and process conditions of the preparation method combining chemical etching and organic coating are as follows:

[0070] Step 1: Prepare organic coating electrolyte solution

[0071]

[0072] Select 0.5 mmol / l of water-soluble triazazine organic compound salt containing the functional groups shown above, 5 mol / l of sodium boronite and 0.5 mol / l of sodium nitrite to mix and prepare an electrolyte solution for organic coating;

[0073] Step 2: Chemical Etching

[0074] After degreasing and cleaning the metal surface, chemical etching is carried out until the metal surface is rough. The main process parameters of chemical etching are:

[0075] Before preparing the superhydrophobic film, it is roughened by chemical etching, and the etchant is CH 3 CH 2 COOH, the chemical etchant concentration is 0.01mol / l, the etching time is 20min, and...

Embodiment 2

[0080]In this embodiment, the substrate metal is pure copper sheet, the size is 50×30×1.5 (mm), and the specific steps and process conditions of the preparation method combining chemical etching and organic coating are as follows:

[0081] Step 1: Prepare organic coating electrolyte solution

[0082]

[0083] Select water-soluble triazazine organic compound salt 2mmol / l, sodium nitrate 0.6mol / l and sodium phosphate 2mol / l containing the above-mentioned functional groups to mix and prepare the electrolyte solution for organic coating;

[0084] Step 2: Chemical Etching

[0085] After degreasing and cleaning the metal surface, chemical etching is carried out until the metal surface is rough. The main process parameters of chemical etching are:

[0086] Before preparing the super-hydrophobic film, it is roughened by chemical etching, and the etching agent is H 2 o 2 and H at a concentration of 0.1 mol / l 2 SO 4 For the mixed reagent with a mixing ratio of 0.1:1, the etching...

Embodiment 3

[0091] In this embodiment, the substrate metal is SUS304 stainless steel with a size of 50×30×0.1 (mm). The specific steps and process conditions of the preparation method combining chemical etching and organic coating are as follows:

[0092] Step 1: Prepare organic coating electrolyte solution

[0093]

[0094] Select 5 mmol / l of water-soluble triazazine organic compound salts containing the above-mentioned functional groups, mix 0.05 mol / l of sodium hydroxide and 0.1 mol / l of potassium carbonate to prepare an electrolytic solution for organic coating;

[0095] Step 2: Chemical Etching

[0096] After degreasing and cleaning the metal surface, chemical etching is carried out until the metal surface is rough. The main process parameters of chemical etching are:

[0097] Before preparing the superhydrophobic film, carry out the roughening by chemical etching method, select the etchant as 5mol / l H 2 o 2 , and 1mol / l HF, their mixing ratio is 0.5:0.1, the etching time is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com