Dyeable and antistatic polypropylene fiber and preparation thereof

A polypropylene fiber and antistatic technology, which is applied in the field of dyeable and antistatic polypropylene fiber, can solve the problems of loss of antistatic performance and lower PEO dissolution performance, and achieve high antistatic performance and good hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

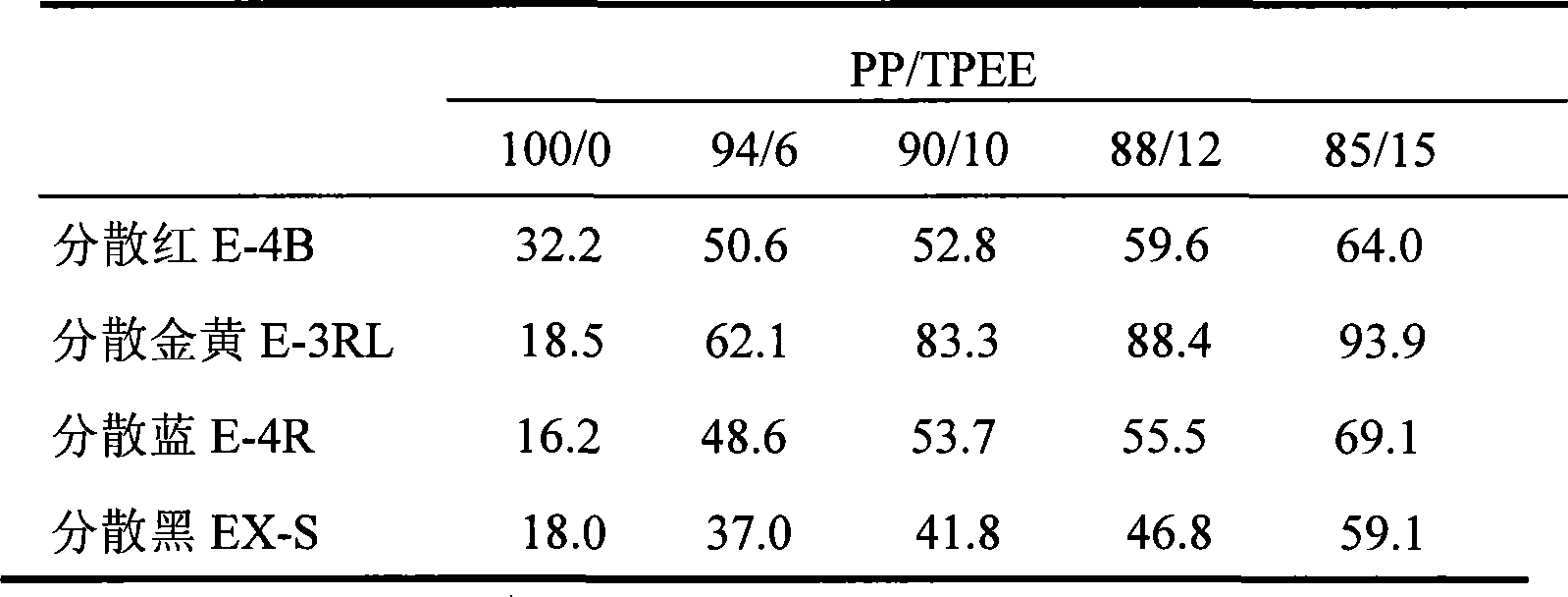

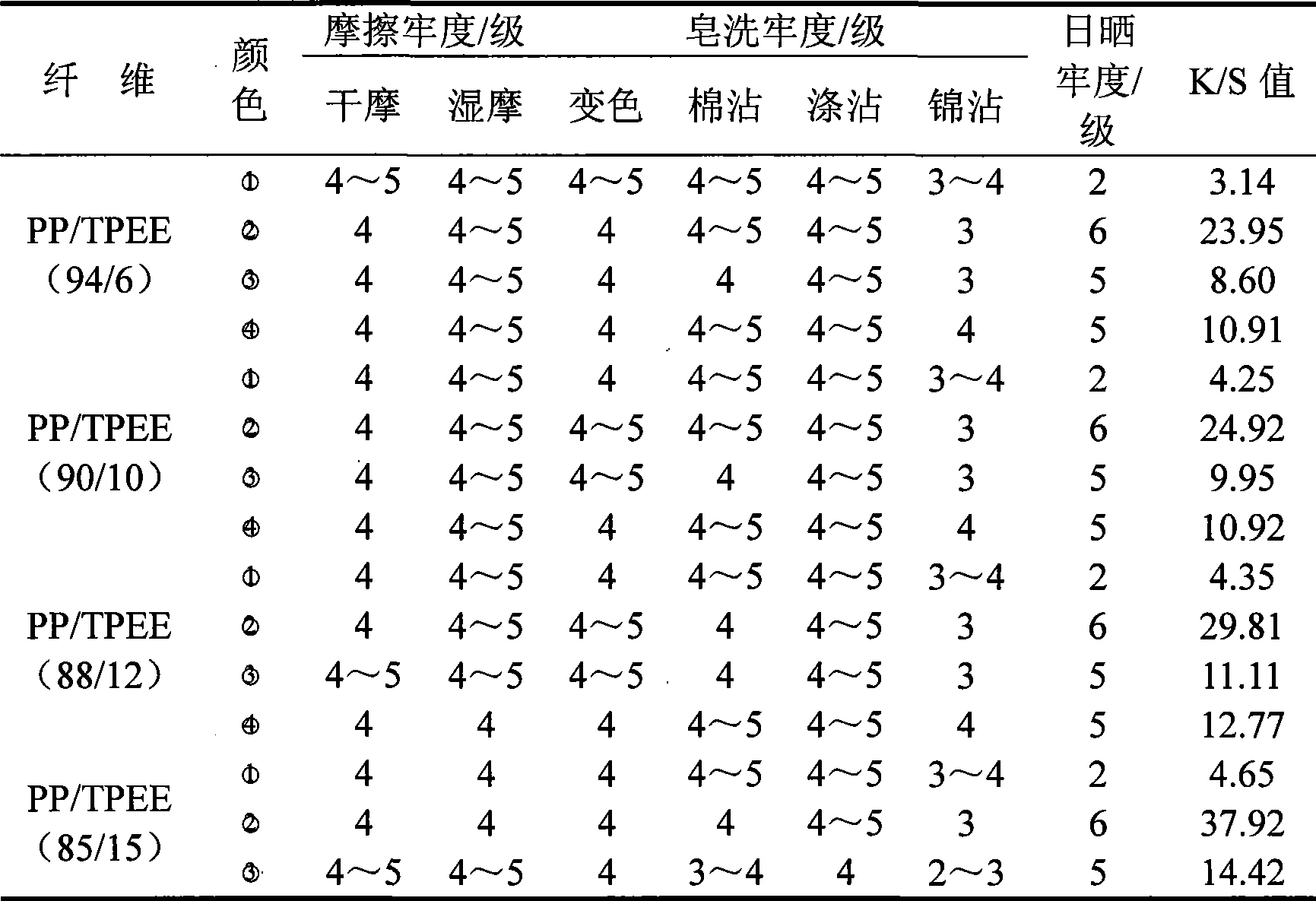

[0043] The isotactic polypropylene PP with a melt index [MI]=17g / 10min and the PBT-PEG copolyether ester with an intrinsic viscosity of 1.02dl / g and a melting temperature of 202°C (polybutylene terephthalate and A copolymer of polyethylene glycol, the mass ratio of polybutylene terephthalate and polyethylene glycol is 40 / 60); mixed in different proportions, in a single-screw melt spinning machine with a diameter of 25mm Melt in medium and mix evenly, and then the blended melt is sent to the spinning assembly quantitatively by the metering pump to extrude, after cooling, oiling and winding, the precursor of the blended fiber is obtained; the precursor is then processed according to BCF (Spinning-stretching-deformation one-step method to prepare bulky filaments) process to obtain finished fibers through stretching, shaping and deformation processing.

[0044] The number of spinneret holes is 24, the hole diameter is 0.30mm, and the aspect ratio is 2:1. The spinning temperature ...

Embodiment 2

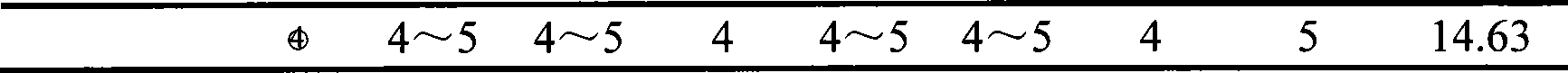

[0057] 12 parts (parts by mass) of pre-dried PBT-PBG copolyether ester (copolymerization of polybutylene terephthalate and polytetramethylene glycol) with an intrinsic viscosity of 1.05dl / g and a melting temperature of 210°C material, the mass ratio of hard segment / soft segment is 45 / 55) and 88 parts (mass parts) PP (MI=35) slices are uniformly mixed, melted in a single-screw melt spinning machine with a diameter of 30mm, and then The metering pump sends the blended melt to the spinning assembly quantitatively according to the regulations, extrudes, cools, oils, and winds to obtain the precursor of the blended fiber; the precursor is stretched and shaped to obtain the finished fiber. The number of spinneret holes is 24, the hole diameter is 0.25mm, the aspect ratio is 2, the spinning temperature is 236°C, the winding speed is 2200m / min, the stretching temperature is 70°C, the setting temperature is 125°C, and the stretching ratio is 2.4 times.

[0058] The fiber breaking stren...

Embodiment 3

[0063] The PP chips of [MI]=23 are pre-dried, and the same copolyetherester chips as in Example 2 are blended in a 92 / 8 (wt) ratio, and melt-spun on the same equipment as in Example 1, The spinning speed is 650m / min, and then stretched and shaped to obtain a specific resistance of the blended fiber of 5.5×10 11 Ω·cm, after being boiled with disperse dyes at normal pressure, the specific resistance value of the fiber is reduced to 2.1×10 10 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com