A method of drying a rapidly dissolving very fine sodium ferric ethylenediamine tetraacetate (nafeedta) product

A technology of sodium ferric ethylenediamine tetraacetate, which is extremely fine, is applied in the direction of drying solid materials, chemical instruments and methods, and drying solid materials without heating, which can solve the problems of slow dissolution and large particle size, and achieve high absorption rate , Improve the yield rate, the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation and drying method of rapidly dissolving iron ethylenediaminetetraacetate:

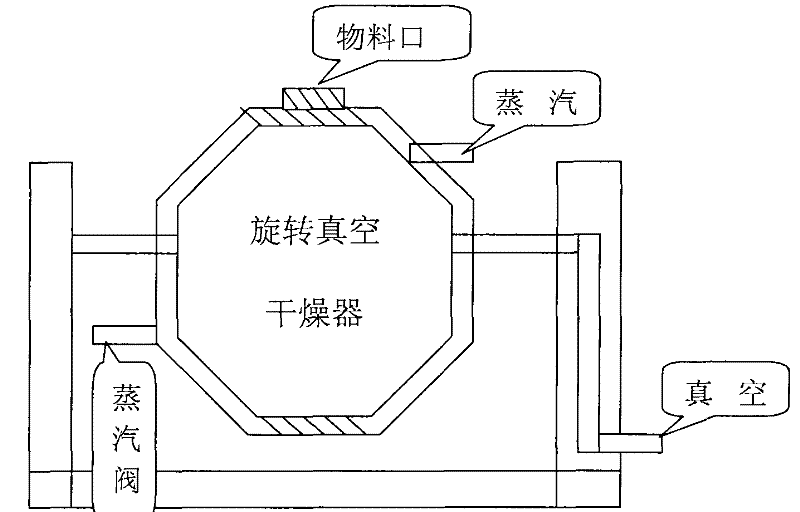

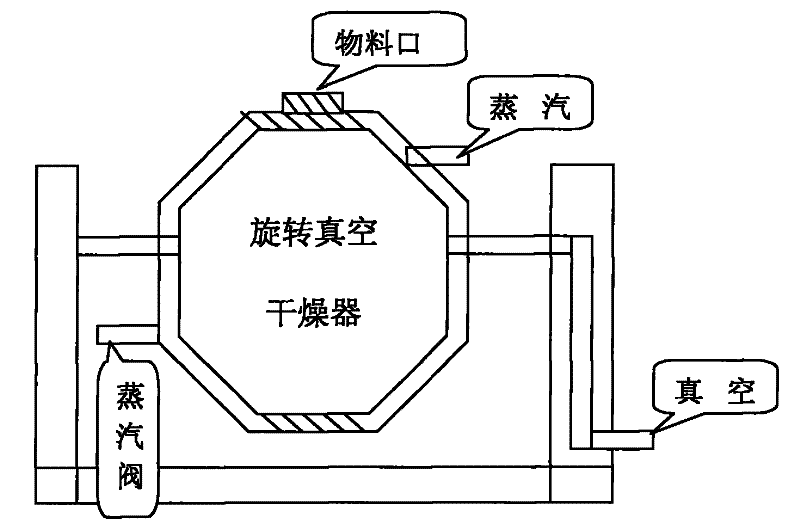

[0023] Take 180kg of ferrous lactate and dissolve it in 500 liters of water, take 240kg of disodium ethylenediaminetetraacetic acid and dissolve it in 1000 liters of water. After mixing the two, adjust the pH value to 5 with sodium bicarbonate and react for 2 hours. In the filter tank, use a vacuum pump to depressurize and filter for solid-liquid separation, concentrate to 400kg, recrystallize 3 times with 80% ethanol, and then transport the NaFeEDTA material to a SZG200 double-cone rotary vacuum dryer heated to 60°C in advance, and vacuum , the vacuum degree is -0.05MPa, start the main motor, and turn the dryer to dry. Adjust the steam control valve at any time during the drying process, control the temperature at 60°C, and dry for 120 minutes; then turn off the steam valve to stop heating, turn off the vacuum valve, stop the vacuum pump, open the negative pressure valve to restore ...

Embodiment 2

[0025] Preparation and drying method of rapidly dissolving iron ethylenediaminetetraacetate:

[0026] Take 110kg of ferrous sulfate and dissolve it in 300 liters of water, take 240kg of disodium ethylenediaminetetraacetic acid and dissolve it in 1000 liters of water. After mixing the two, adjust the pH value to 7 with sodium hydroxide and react for 1 hour. In the filter tank, use a vacuum pump to depressurize and filter for solid-liquid separation, concentrate to 400kg, recrystallize 3 times with 80% ethanol, and then transport the NaFeEDTA material to a SZG200 double-cone rotary vacuum dryer heated to 100°C in advance, and vacuum , the vacuum degree is -0.1MPa, start the main motor, and turn the dryer to dry. Adjust the steam control valve at any time during the drying process, control the temperature at 120°C, and dry for 150 minutes; then turn off the steam valve to stop heating, turn off the vacuum valve, stop the vacuum pump, open the negative pressure valve to restore th...

Embodiment 3

[0028] The preparation method of fast-dissolving ultra-fine ferric edetate:

[0029] Get 160 kg of ferric chloride and dissolve it in 500 liters of water, get 240 kg of ethylenediamine tetraacetic acid disodium salt and dissolve it in 1000 liters of water, after the two are mixed, adjust the pH value to 5 with sodium bicarbonate and sodium hydroxide, react for 0.1 hour, The reaction mixture was passed through a LLW type horizontal screw discharge filter centrifuge with a rotation speed of 4500r / min, centrifuged for 5min, concentrated to 500kg, recrystallized with 80% ethanol for 3 times, and then the NaFeEDTA material was transported to SZG200 preheated to 80°C Double-cone rotary vacuum dryer, vacuumize, the vacuum degree is -0.06MPa, start the main motor, and rotate the dryer to dry. Adjust the steam control valve at any time during the drying process, control the temperature at 110°C, and dry for 110 minutes; then turn off the steam valve to stop heating, turn off the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com