Co-Ga co-blended ZnO based diluted semi-conductor thin-film and manufacturing method thereof

A dilute magnetic semiconductor and thin-film technology, which is used in the manufacture of semiconductor/solid-state devices, the manufacture/processing of electromagnetic devices, and the selection of materials, etc., can solve problems with room temperature ferromagnetism, high carrier concentration, etc. Mature craftsmanship and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Preparation of ceramic target. Weigh pure ZnO, Co 2 o 3 , Ga 2 o 3 powder, wherein the molar percentage of Co is 2%, the molar percentage of Ga is 3%, and the weighed ZnO, Co 2 o 3 , Ga 2 o 3 The powder was poured into a ball mill jar equipped with agate balls, and milled on a ball mill for 24 hours to make ZnO, Co 2 o 3 , Ga 2 o 3 The powder is well mixed and finely ground. Then the raw materials are separated and dried, added with a binder for grinding, and pressed into shape. Put the formed green body into the sintering furnace, first keep it warm at 800°C for 2 hours to volatilize the binder, then raise the temperature to 1250°C for 2 hours and sinter to obtain Zn(Co, Ga)O ceramic target.

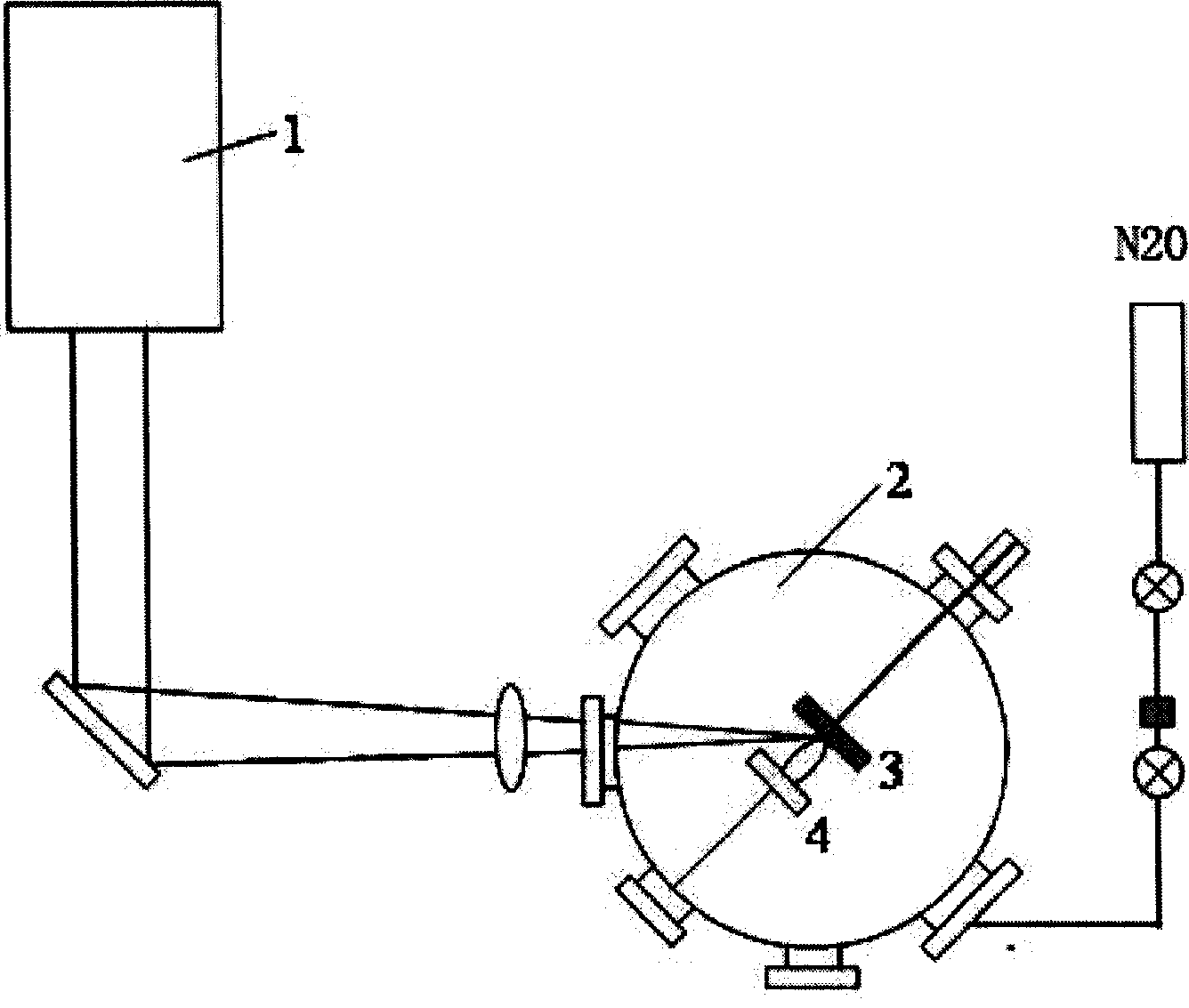

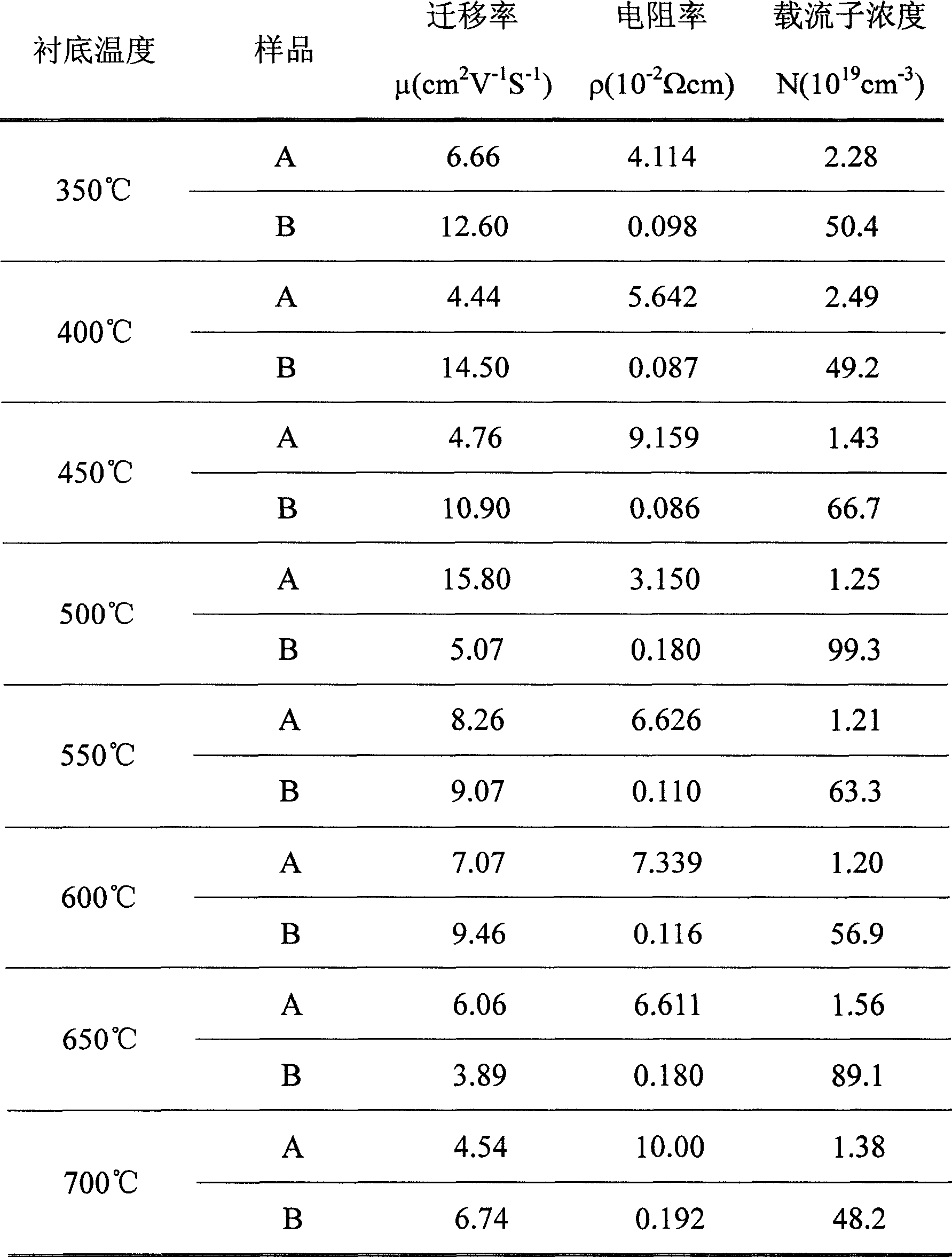

[0018] 2) Use a 2-inch quartz polished wafer as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition system. The vacuum degree of the growth chamber is evacuated to less than 8.0×10 -4 Pa, then heat th...

Embodiment 2

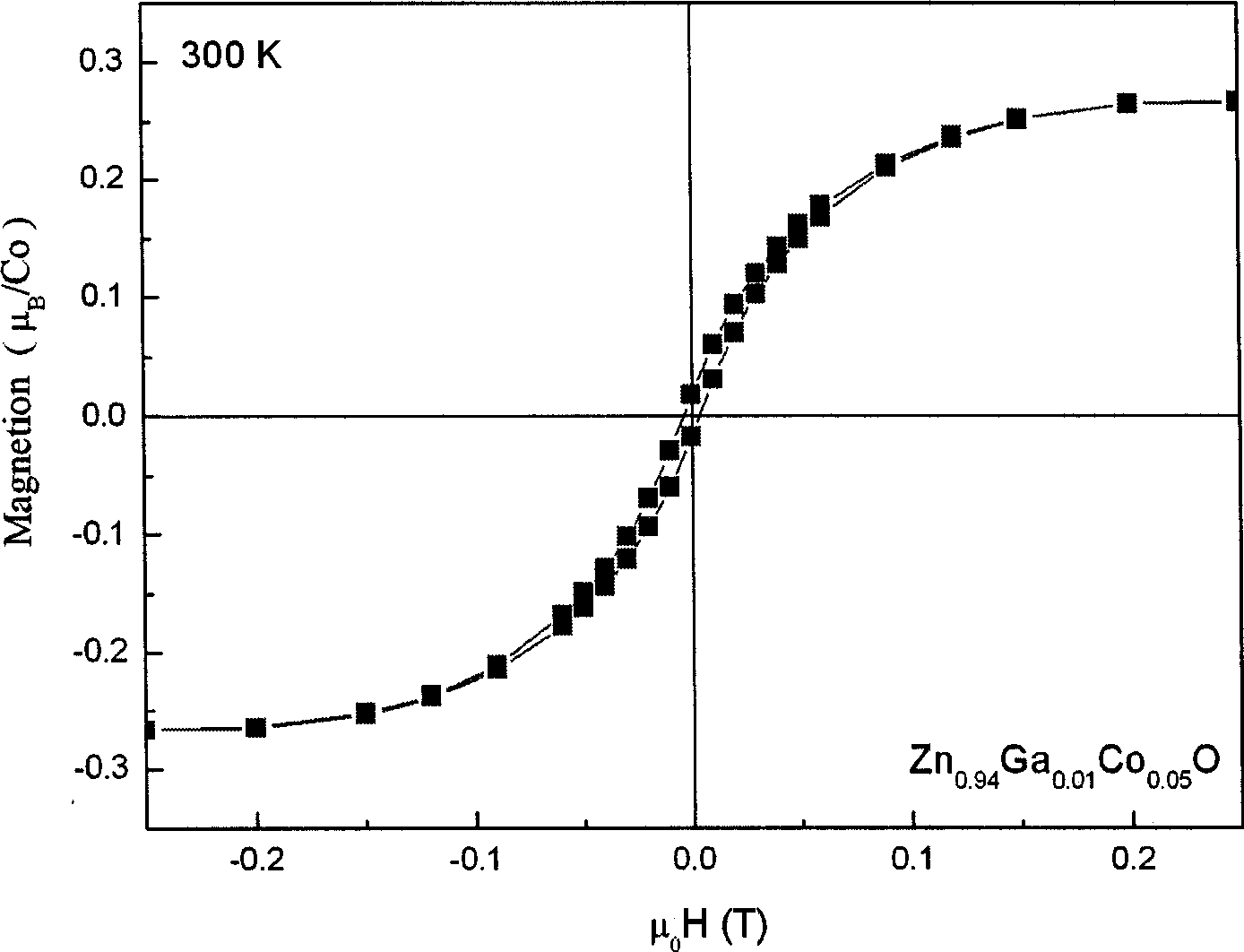

[0022] The target material preparation and film deposition process are the same as in Example 1, wherein the molar percentage of Co is 10%, and the molar percentage of Ga is 3%, and a Co-Ga co-doped ZnO dilute magnetic semiconductor film with high Carrier concentration and room temperature ferromagnetism.

Embodiment 3

[0024] The target preparation and film deposition process are the same as in Example 1, the difference is that the substrate is sapphire, and the substrate temperature rises to 700°C, and a Co-Ga co-doped ZnO dilute magnetic semiconductor film with high carrier concentration and Ferromagnetic at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com