Method for preparing hydrochloric acid and ammonia sulfate by decomposing ammonium chloride in sulfuric acid medium

A technology of ammonium chloride and ammonium sulfate, applied in the field of salt chemical industry, can solve the problems of unutilized resource chlorine, harsh operating conditions, difficult industrialization, etc., and achieve deep development and utilization, high utilization value of finished products, and low investment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

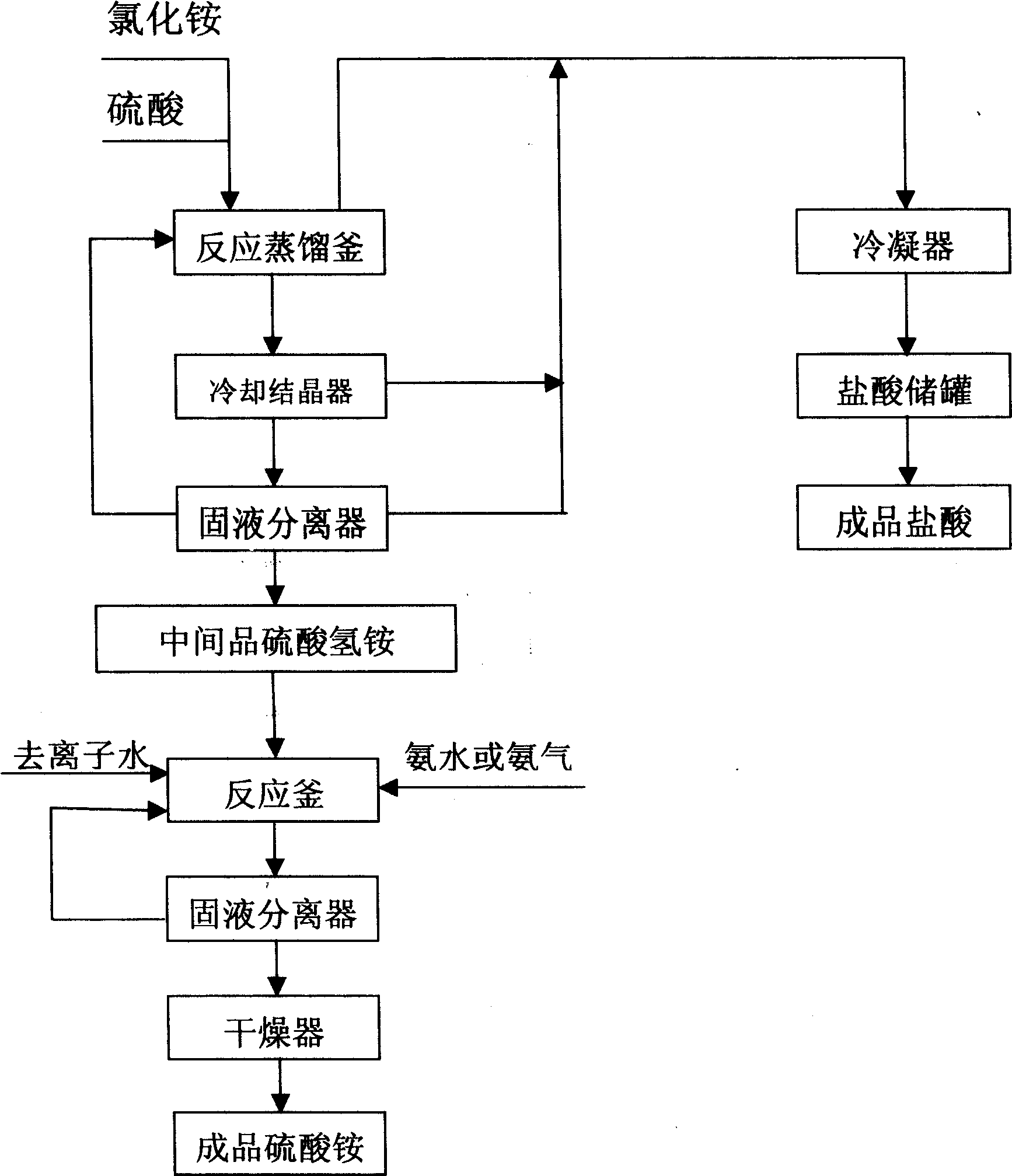

[0034] See figure 1 . Take by weighing 48.03g ammonium chloride and join concentration and be dissolved in the sulfuric acid medium of 20wt%, the mol ratio of sulfuric acid and ammonium chloride is 0.5; The mixed solution (mother liquor 1) that will prepare is dropped in the reactor, heat up until solution boils At this time, a large amount of steam is generated, which is sent into the condenser through the conduit to condense, and the condensate is hydrochloric acid; pipette 10mL of the collected hydrochloric acid solution, and use a concentration of 0.1mol / L sodium hydroxide standard solution to titrate and determine the concentration of hydrochloric acid. 3.95mol / L, the recovery rate of HCl reaches 60%; The bottom liquid crystallizes and separates out ammonium bisulfate at room temperature, filters and obtains crude product ammonium bisulfate, and can obtain ammonium bisulfate product through refining; Prepared ammonium bisulfate Concentration is the solution (mother liquo...

Embodiment 2

[0036] See figure 1 . Take by weighing 145.17g ammonium chloride and join concentration and be dissolved in the sulfuric acid medium of 60wt%, the mol ratio of sulfuric acid and ammonium chloride is 1.0; The mixed solution (mother liquor I) that will prepare is dropped in the reactor, normal pressure (1atm ), heat up until the mixed solution boils, the temperature is 80°C, at this time there are a lot of HCl and H 2 The vapor composed of O is generated to keep the solution in a boiling state; the HCl and H 2 The steam composed of O is sent into the condenser through the conduit to condense, and the condensate is hydrochloric acid; pipette 10mL of the collected hydrochloric acid solution, and use the sodium hydroxide standard solution with a concentration of 0.1mol / L to titrate and measure the concentration of hydrochloric acid to be 12mol / L, The recovery rate of HCl reaches 96%; The bottom liquid crystallizes at room temperature (20 ℃) for 5 hours and separates out ammoniu...

Embodiment 3

[0038] See figure 1 . Take by weighing 205.95g ammonium chloride and join in concentration and be dissolved in the sulfuric acid medium of 80wt%, the mol ratio of sulfuric acid and ammonium chloride is 2.5; The mixed solution (mother liquor I) that will prepare is dropped in the reactor, normal pressure (1atm) Next, raise the temperature until the mixed solution boils, the temperature is 110°C, at this time there are a lot of HCl and H 2 The steam composed of O is generated, the condenser tube condenses, and the condensate is hydrochloric acid; pipette 10mL of the collected hydrochloric acid solution, and use a sodium hydroxide standard solution with a concentration of 0.1mol / L to titrate and determine that the concentration of hydrochloric acid is 12mol / L, and the recovery of HCl The rate reaches 99%; the liquid at the bottom of the kettle is cooled to precipitate crystals, the crystallization temperature is 25°C, and the crystallization time is 3 hours. The separated and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com