Method for producing human amyloid A<beta>1-42 with methylotrophy yeast

A methylotrophic yeast, using methyl technology, applied in the field of protein production, purification and identification, to achieve the effect of simple medium composition, low production cost and high expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Human amyloid Aβ 1-42 Gene Acquisition and Amplification

[0042] (1) Human amyloid Aβ 1-42 Preparation of DNA:

[0043] A synthetic approach will encode human Aβ 1-42 The genetic codons of amino acids were all replaced with yeast preferred codons, and the specific sequence was as follows: 5'-GATGCTGAATTTAGACATGATTCTGGTTACGAAGTTCATCATCAGAAGTTGGTCTTCTTTGCTGAAGATGTTGGTTCTAACAAGGGTGCTATTATTGGTTTGATGGTTGGTGGTGTTGTTATTGCT-3' (SEQ ID NO.1).

[0044] Take the above DNA, and set up 50 μl of PCR reaction system according to the following ratio:

[0045] Take the human Aβ synthesized above 1-42 DNA as template 1μl (2pmol / μl); containing Mg 2+ 5 μl of 10×PCR buffer; 2.5 μl of dNTPs (each 2.5 mmol / L); the partial sequence of the yeast α factor signal peptide was introduced at the 5' end, and the upstream primer: 5'-CGCCTCGAGAAGAGAGATGCTGAATTTAG-3' (SEQ ID NO.2) 1μl (20pmol / μl) contains XhoI restriction site; downstream primer: 5'-CCACAACAATAACGAATTCTTAAGCGCGC-3' (S...

Embodiment 2

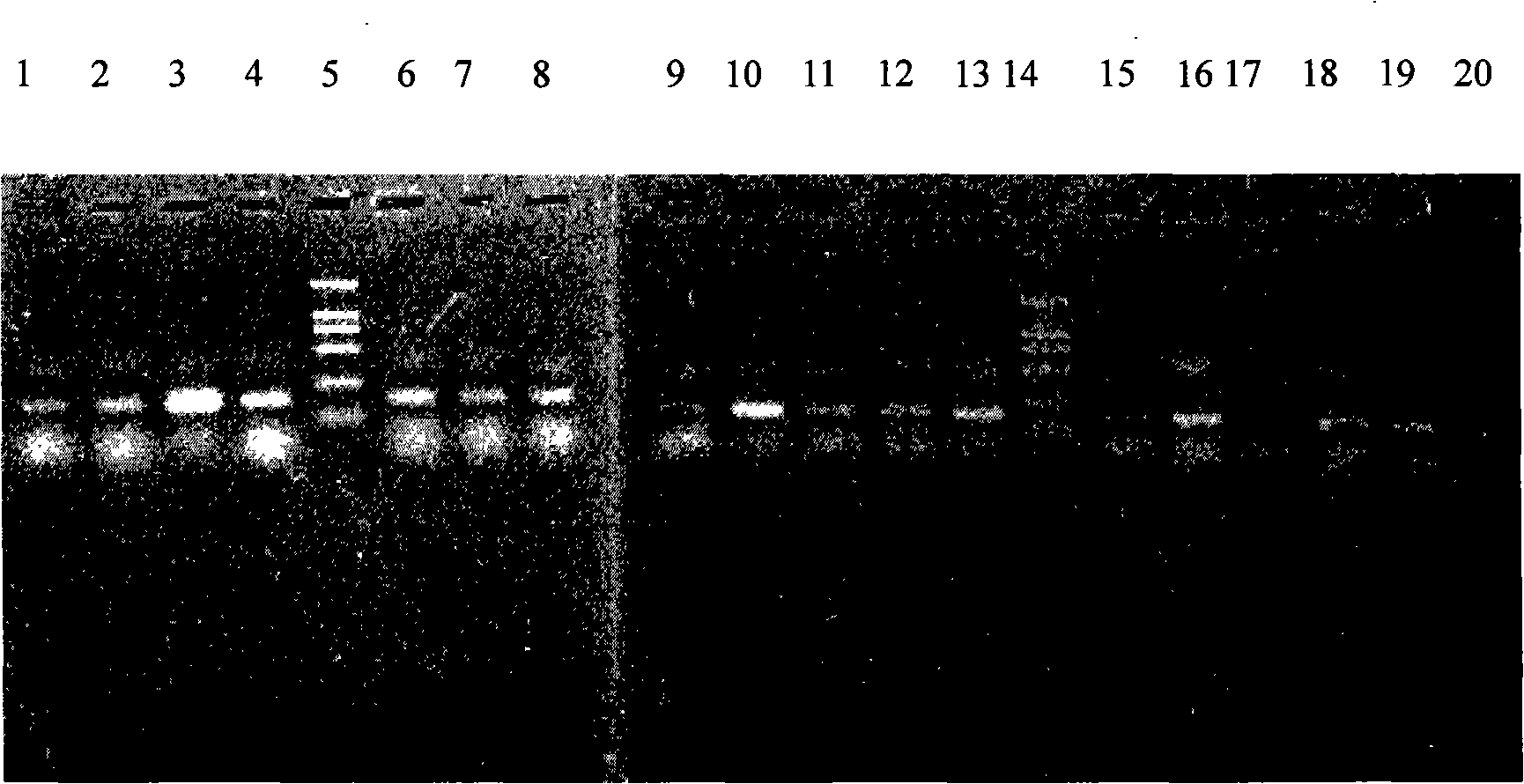

[0052] Example 2: pPICZα-hAβ 1-42 Transformation of Pichia pastoris X-33

[0053] Take the culture medium with correct sequencing, extract the plasmid DNA according to the instructions of the plasmid extraction kit, and perform quantitative analysis by agarose gel electrophoresis. Take 20~25μg pPICZα-hAβ 1-42, The recombinant plasmid was digested with SacI (linearized), extracted with phenol / chloroform and precipitated with ethanol. The linearized plasmid was dissolved in 10 μl ultrapure water and kept on ice for later use.

[0054] Pick a single colony from the YPD negative culture plate of Pichia pastoris X-33 (YPD agar plate without antibiotics), inoculate it in 5ml of YPD medium, shake it at 250rpm, 30°C for 8 hours, and prepare yeast for electroporation competent cells.

[0055] Then take 80 μl of the above-mentioned competent bacteria, mix them with 20-25 μg of linearized recombinant expression plasmids, transfer them into a 0.2 cm electroporation cup for electropora...

Embodiment 3

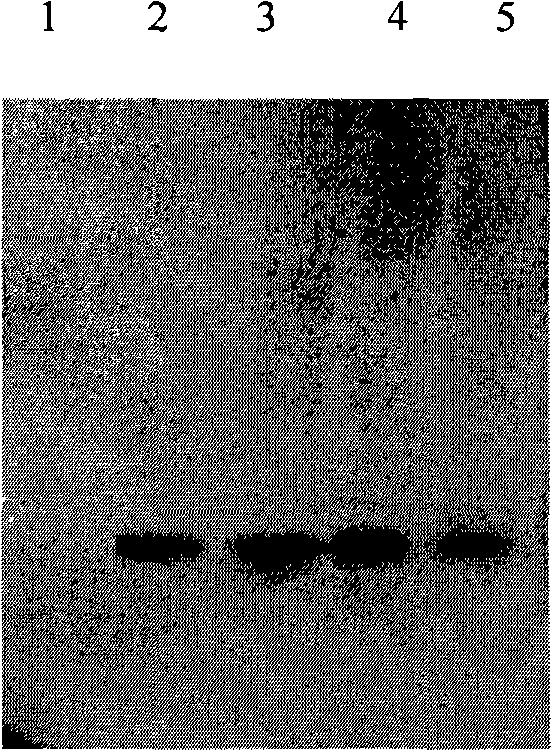

[0057] Embodiment 3: recombinant human amyloid Aβ 1-42 expression

[0058] Inoculate the positive clones of the above identification results in 10ml of BMGY (pH6.0) medium, culture with shaking at 30°C for 24 hours, until OD 600 Cells were collected when reaching 2.0-6.0. Resuspend the cell pellet with an equal volume (10ml) of BMMY (pH6.0), culture with shaking at 30°C, and induce expression. During the induction process, methanol was supplemented every 24 hours to a final concentration of 0.5%, and sterilized ultrapure water was supplemented at the same time to keep the total volume of the fermentation broth unchanged. At 0, 24, 48, 72, 96, 120, 144 and 168 hours of culture, 0.5 ml of fermentation broth was taken respectively, and the supernatant was collected by centrifugation for protein analysis (SDS-PAGE, Western Blot).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com