Aramid fiber fabric and carbon fibre composite core for overhead transmission line conductor

An overhead transmission line, aramid fiber technology, applied in circuits, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of large bending radius and full production rate, and achieve large bending radius. , The effect of slow production speed and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

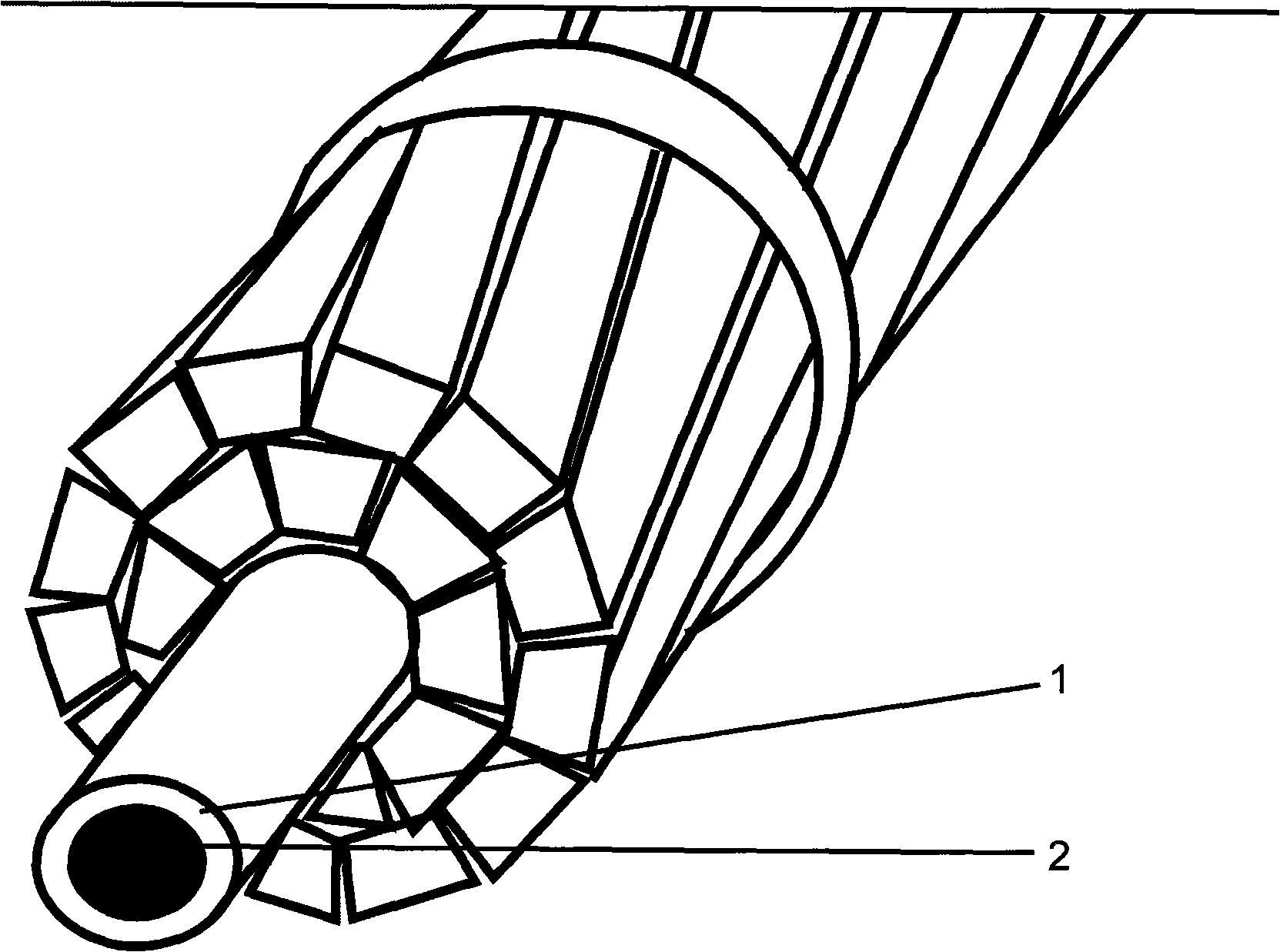

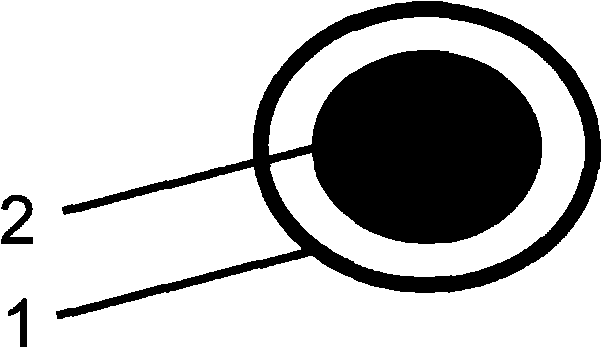

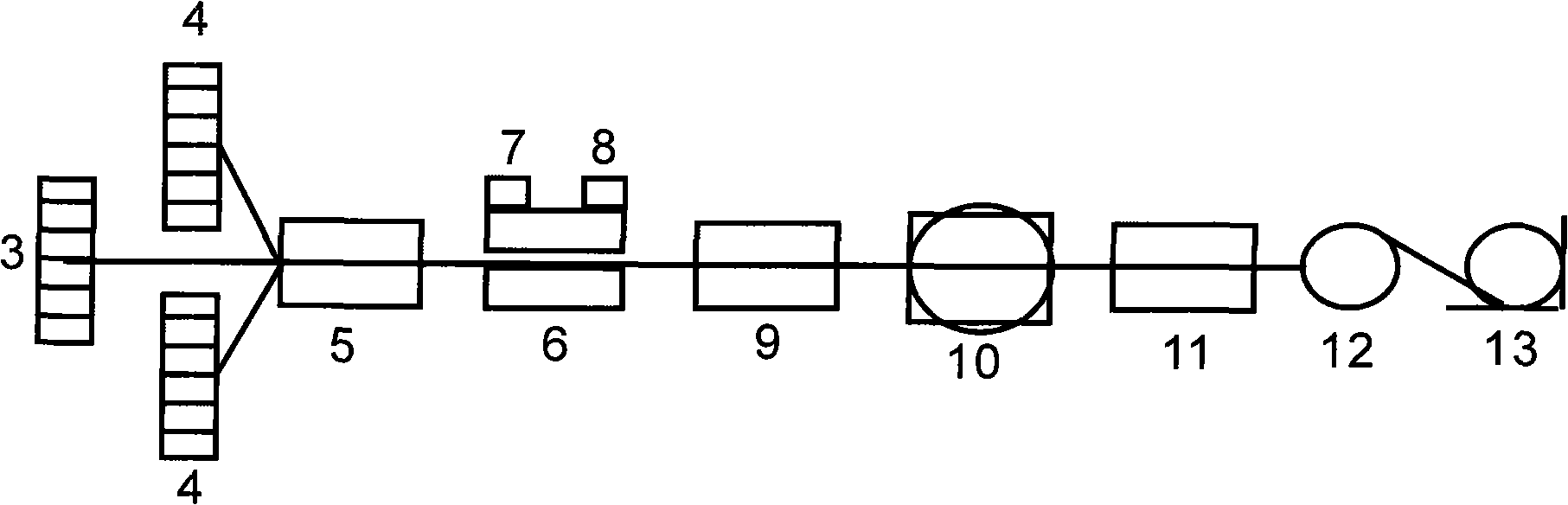

[0019] image 3 It is a schematic diagram of the production process of the present invention: the label description in the accompanying drawings:

[0020] Aramid fiber and epoxy resin bonding layer 1; carbon fiber composite core 2; manufacturing process: carbon fiber tow gathering frame 3; aramid fiber multi-layer creel 4; resin tank 5; heating mold 6; curing area 7; shaping area 8; oven 9; bridge molding machine 10; preheating oven 11; tractor 12; winder 13;

[0021] exist figure 1 , figure 2 , image 3 In the schematic diagram of the aramid fiber and carbon fiber composite core used for overhead transmission line conductors, the carbon fiber bundles are pulled out in a circular shape through the gathering frame, and the aramid fibers are pulled out from the multi-layer yarn The frame 4 wraps the carbon fiber round body and pulls it out to avoid the occurrence of carbon fiber and aramid fiber bruising and fiber fluffing. In order to prevent the aramid fiber yarn from bei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com