Method for preparing active carbon

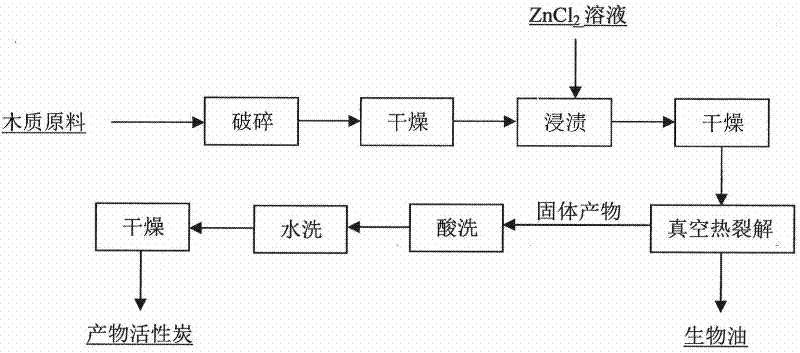

A technology for preparing activated carbon and drying, which is applied in the field of preparation of adsorption materials, can solve problems such as micropore blockage and carbon structure damage, and achieve the effects of increasing specific surface area, cleaning the process, and reducing expansion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] When the mass ratio of Chinese fir sawdust to zinc chloride is 1:1, the Chinese fir sawdust is immersed in the zinc chloride solution for 24 hours, the dried sample is weighed, placed in a reaction furnace, and vacuumized. The activated carbon is prepared under the conditions of system pressure of 10.5kPa, heating rate of 5°C / min, final cracking temperature of 400°C, and holding time of 60min. After testing, the iodine adsorption value of the prepared activated carbon was 916.28 mg / g, and the methylene blue adsorption value was 250.14 mg / g.

Embodiment 2

[0021] When the mass ratio of Chinese fir sawdust to zinc chloride is 1:1, the Chinese fir sawdust is immersed in the zinc chloride solution for 24 hours, the dried sample is weighed, placed in a reaction furnace, and vacuumized. The activated carbon was prepared under the condition that the system pressure was 50.5kPa, the heating rate was 5°C / min, the cracking final temperature was 500°C, and the holding time was 60min. After testing, the prepared iodine adsorption value is 976.68 mg / g, and the methylene blue adsorption value is 323.28 mg / g.

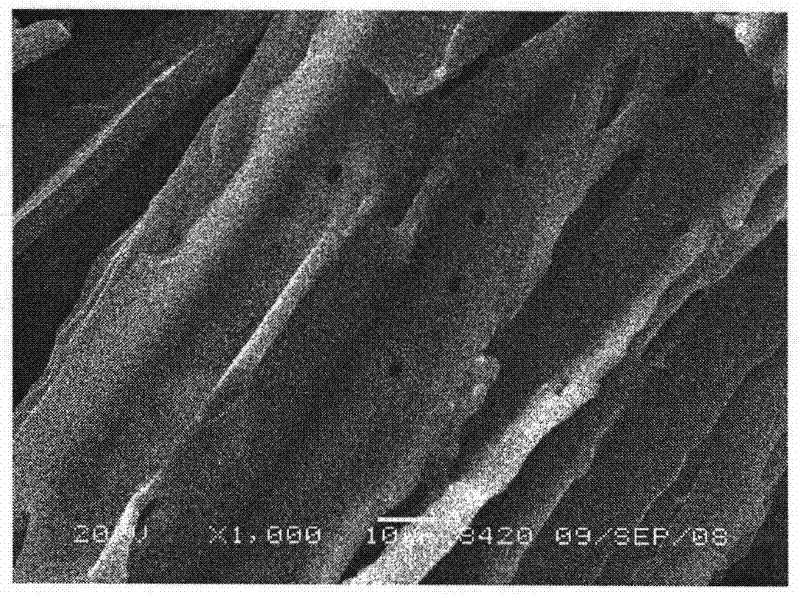

Embodiment 3

[0023] When the mass ratio of Chinese fir sawdust to zinc chloride is 1:1, the Chinese fir sawdust is immersed in the zinc chloride solution for 24 hours, the dried sample is weighed, placed in a reaction furnace, and vacuumized. Under the condition that the system pressure is 30.5kPa, the heating rate is 5°C / min, the final cracking temperature is 500°C, and the holding time is 60min, the SEM photo of the activated carbon is shown in the attached figure 2 . After testing, the prepared iodine adsorption value is 1008.69 mg / g, and the methylene blue adsorption value is 321.61 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com