Method for producing xylitol and arabinose at the same time

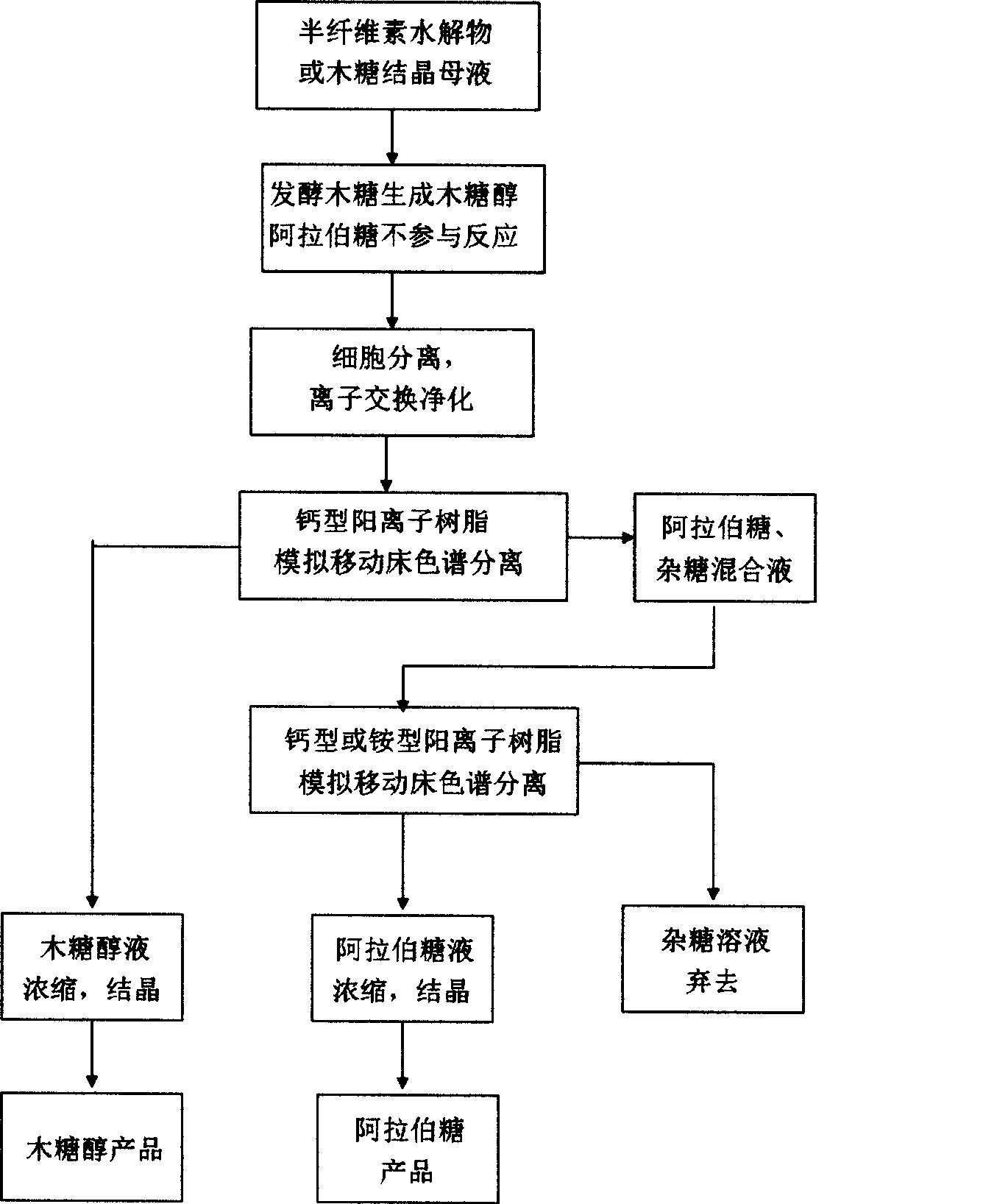

A technology of arabinose and xylitol, which is applied in the biological field, can solve the problems of low product yield, potential safety hazards, and low separation efficiency, and achieve the effect of reducing production costs and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

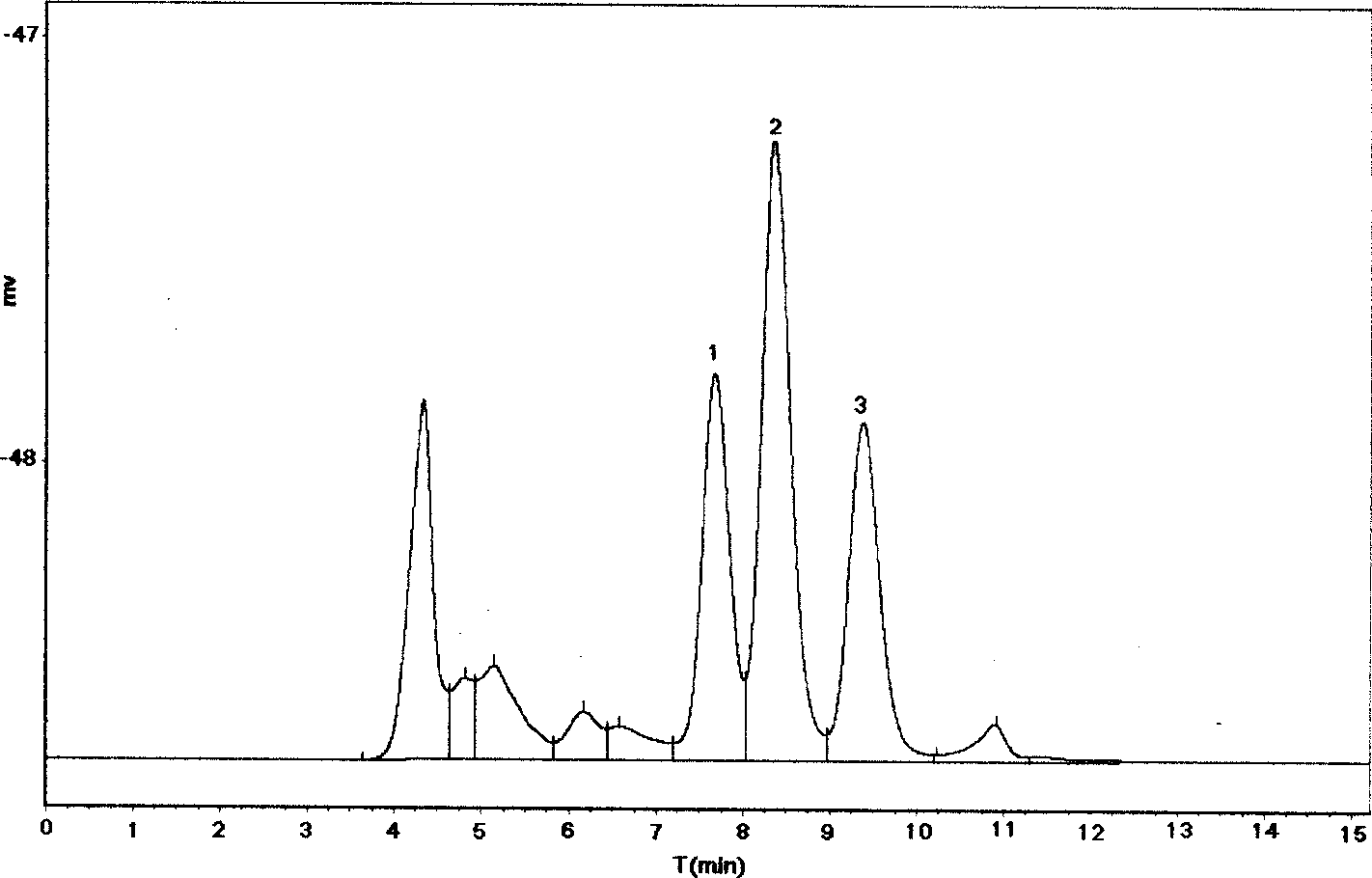

[0065] 40kg corn husks, add 160L of water, boil. Filter off the liquid part, wash the residue once with water, add 80 L of 2% (w / w) sulfuric acid solution to the dried residue, and hydrolyze in a hydrolysis reactor at 125°C for 2 hours. Remove the residue by filtration, adjust the filtrate to pH 3 with calcium carbonate, remove the precipitate by filtration, add 1 kg of activated carbon to the filtrate, remove the activated carbon after adsorption treatment for 30 minutes, and then pass through the cation and anion exchange chromatography columns in turn to obtain a colorless and transparent syrup , and concentrated to the required concentration under reduced pressure. The ratio of glucose, xylose, and arabinose content in this syrup is approximately 1:2:1 (see image 3 ).

Embodiment 2

[0067] Add 280L of 2.4% (w / w) sulfuric acid solution to 40Kg of dried bagasse, and hydrolyze at 125°C for 2 hours. All the other follow-up processing steps are the same as in Example 1. The sugar syrup prepared from bagasse hemicellulose hydrolyzate has a content ratio of glucose, xylose and arabinose of about 1:10:1.

Embodiment 3

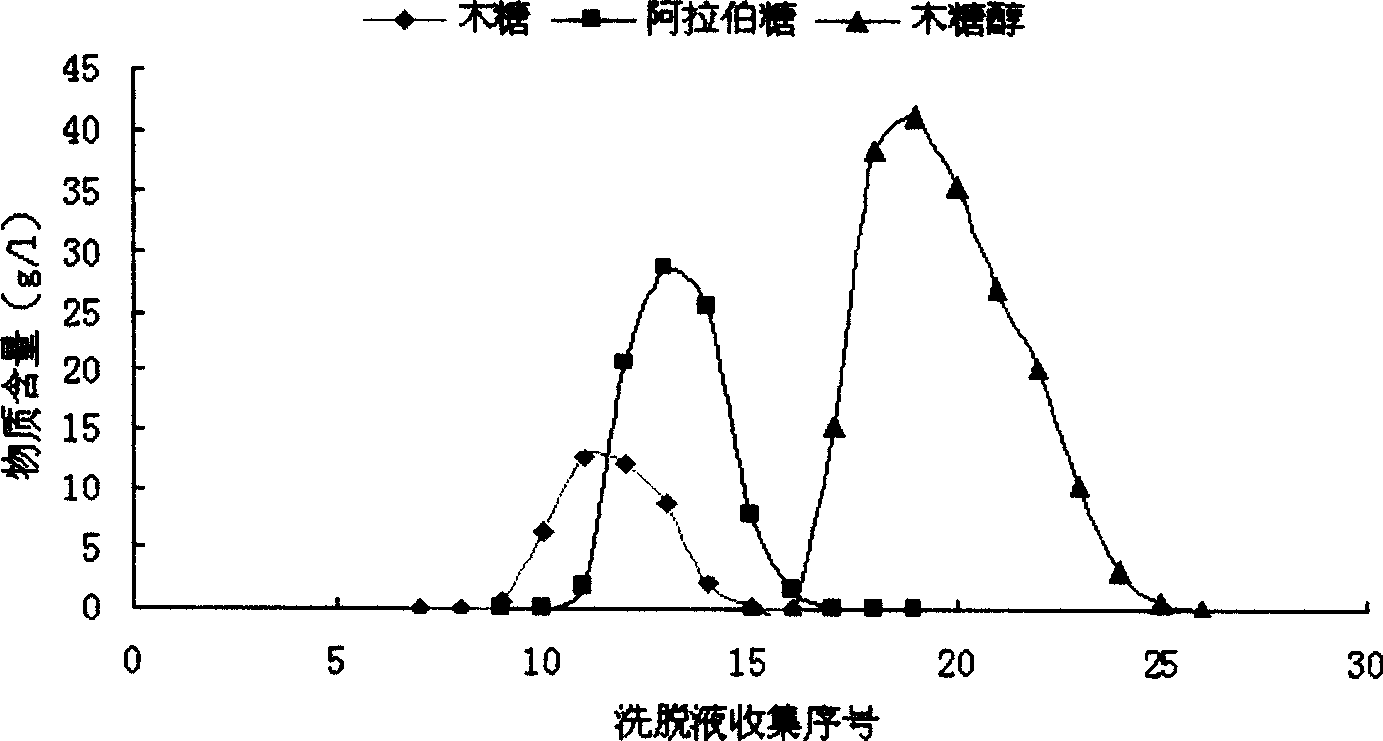

[0069] The corn bran hemicellulose hydrolyzate obtained in Example 1 was taken, and the hot water extract from 100 g of rice bran was added to each liter of fermentation broth to adjust the total sugar to 250 g / L, which contained about 120 g / L of xylose and arabinose 80g / L, sterilized at 110°C for 10 minutes. A 5L fermenter (Biotech-5BG; Shanghai Baoxin Bioengineering.Equipment, Shanghai, China) with a capacity of 3L was inoculated with fresh Candida tropicalis CCTCC M 205067 (Candida tropicalis CCTCC M 205067), with an inoculation volume of 5% (v / v), Ventilation volume 1vvm, stirring speed 300rpm, culture at 33°C for about 30h, xylose is converted into xylitol, and arabinose does not participate in the reaction ( Figure 4 ). After the fermentation was stopped, the cell pellet was collected by centrifugation, and the pelleted cells were adjusted into a slurry with fresh medium, and then injected back into the fermenter. The medium was topped up to the fill volume of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com